Tool type steel pipe cutting machine

A cutting machine and tool-type technology, applied in the field of pipe cutting equipment, can solve the problems of poor processing quality, high labor intensity, pollution of the environment, etc., achieve fast cutting speed, improve work efficiency, and avoid the effect of knife-edge eversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

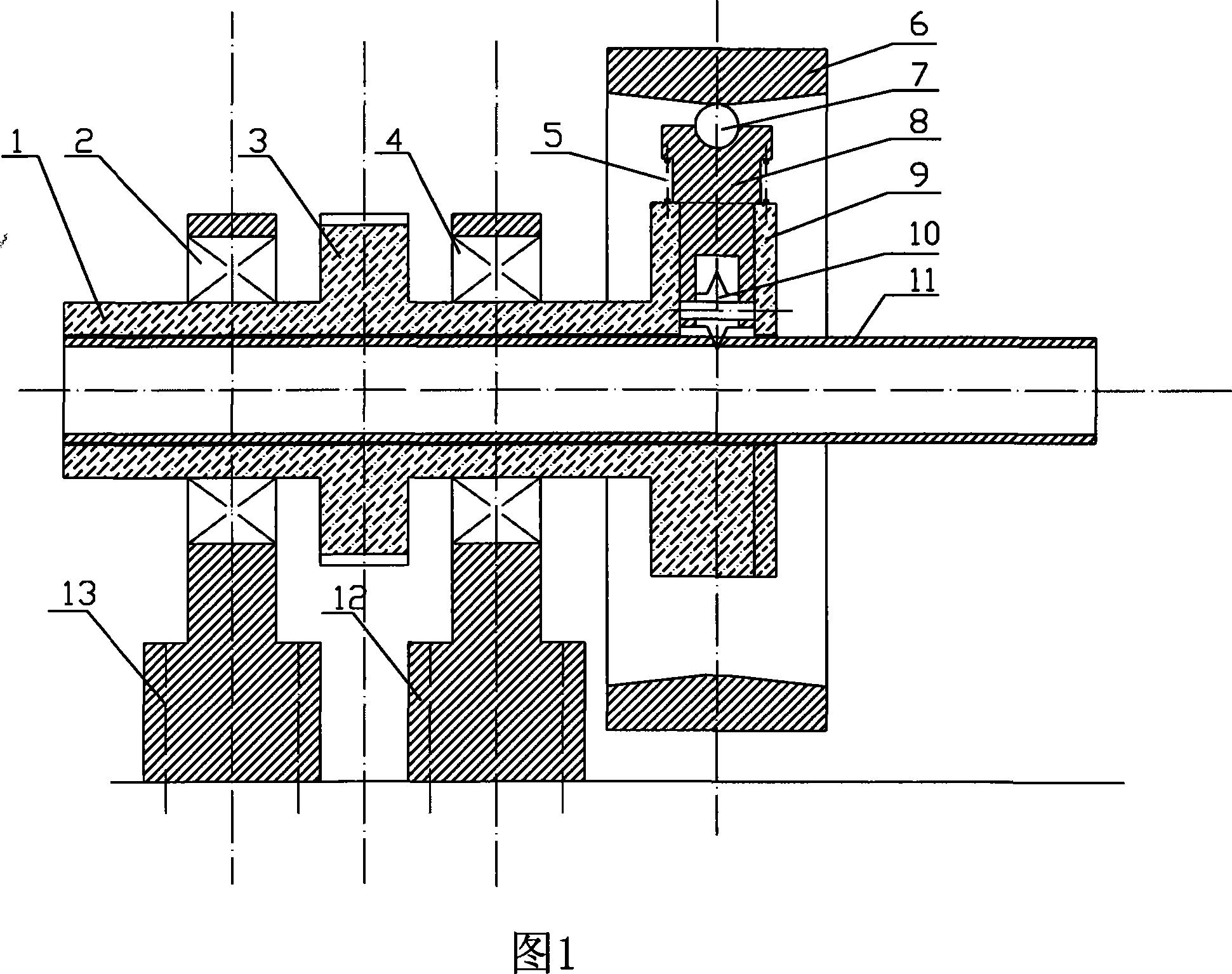

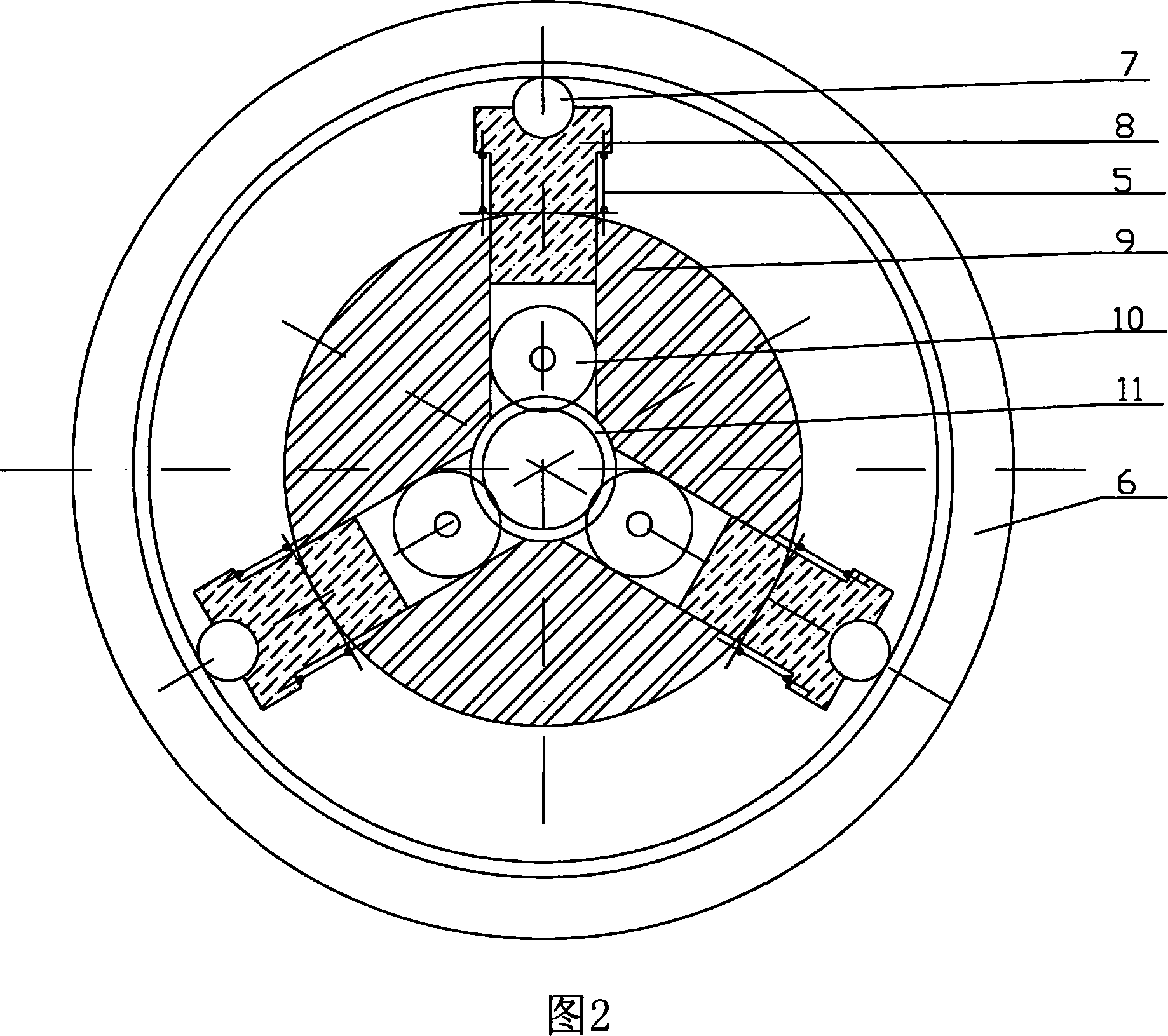

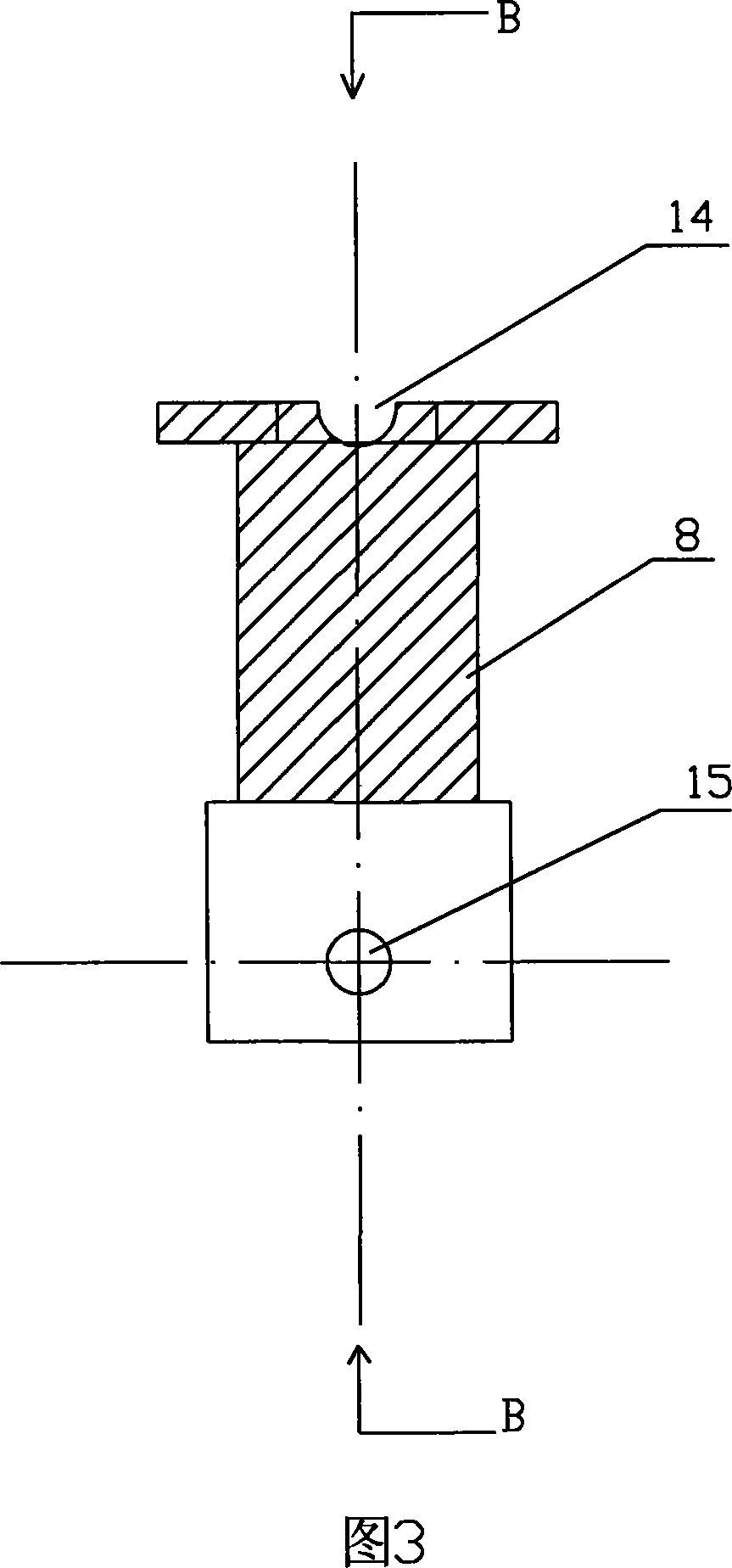

[0018] In Fig. 1, the specific technical solution of the present invention is provided, the knife rest 1 is cylindrical, and the knife rest 1 is fixed on the bearing supports 12, 13 through bearings 2, 4, and a belt pulley is fixed in the middle of the knife rest 1 3. There is a driving motor (not shown in the figure) to drive the knife rest 1 to rotate through a belt. A chuck 9 is fixed on the right end of the tool rest 1, and the axes of the tool rest 1 and the chuck 9 overlap each other, and the chuck 9 is a chuck used on a common lathe. A cutter head 8 is placed in the chute arranged radially at an angle of 120° C. on the chuck 9 . The inner end of the cutter head 8 is fixed with a hob 10 through a groove and a rotating shaft. The outer diameter of the hob 10 is smaller than the width of the chute of the chuck 9 and is located inside it. The outer end of cutter head 8 has a circle of bosses, and a back-moving spring 5 is arranged to be enclosed within the outer part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com