Temperature and solidification rate real-time monitoring device for polymer based composite material forming process

A composite material and molding process technology, applied in the direction of measuring devices, thermometers with physical/chemical changes, thermometers, etc., can solve the problem of inability to monitor temperature and curing degree simultaneously in real time, low measurement accuracy of small test pieces, and not being widely used, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

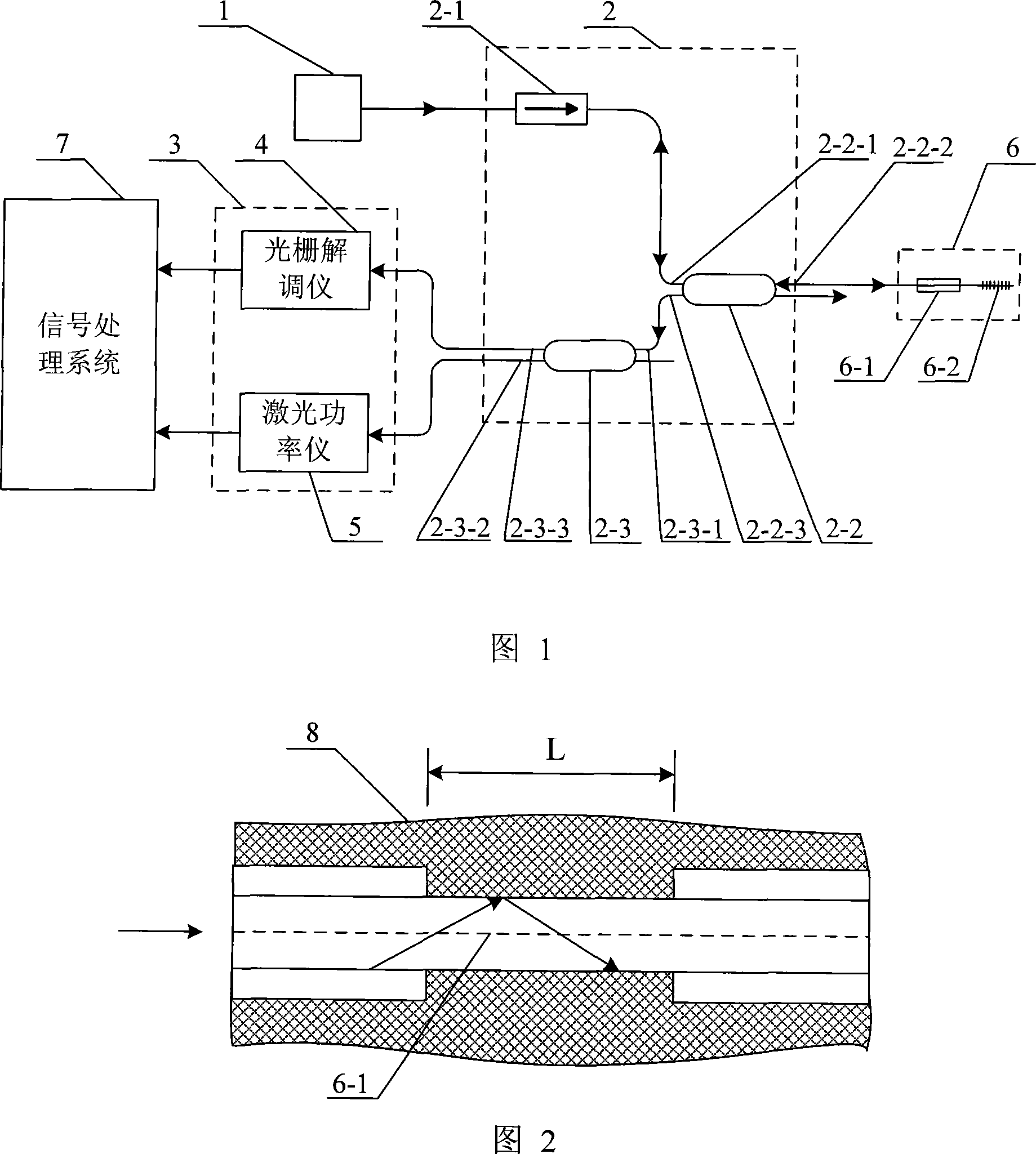

[0011] Specific Embodiment 1: This embodiment is described in conjunction with FIG. 1 and FIG. 2. This embodiment is composed of a laser 1, an optical transmission line assembly 2, an optical receiver 3, a sensing module 6 and a signal processing system 7;

[0012] The optical transmission line assembly is composed of an isolator 2-1, a first coupler 2-2 and a second coupler 2-3, the output end of the laser 1 is connected to the input end of the isolator 2-1, and the isolator 2-1 The output end is connected to the first port 2-2-1 of the first coupler 2-2, the second port 2-2-2 of the first coupler 2-2 is connected to the port of the sensor module 6, and the first coupler 2- The third port 2-2-3 of 2 connects the first port 2-3-1 of the second coupler 2-3, the second port 2-3-2 of the second coupler 2-3 and the third port 2- 3-3 are respectively connected to the two input terminals of the optical receiver 3, and the two output terminals of the optical receiver 3 are respective...

specific Embodiment approach 2

[0013] Specific embodiment two: this embodiment is described in conjunction with Fig. 1, the difference between this embodiment and specific embodiment one is that the optical receiver 3 is made up of a grating demodulator 4 and a laser power meter 5, and the grating demodulator 4 The input end of the input end and the laser power meter 5 are respectively connected to the second port 2-3-2 and the third port 2-3-3 of the second coupler 2-3, the output end of the grating demodulator 4 and the laser power meter The output terminals of 5 are respectively connected to the two data input terminals of the signal processing system 7 . Other compositions and connection methods are the same as those in Embodiment 1.

specific Embodiment approach 3

[0014] Specific embodiment three: This embodiment is described in conjunction with Fig. 1 and Fig. 2. The difference between this embodiment and specific embodiment one is that the distance between the optical fiber refractive index sensor 6-1 and the Bragg grating 6-2 connected in series is 1-2 cm, and other The composition and connection method are the same as those in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com