PC/ABS (Polycarbonate/Acrylonitrile-Butadiene-Styrene) alloy with low odor and low emission and preparation method of PC/ABS alloy

A low-emission, low-odor technology, applied in low-emission PC/ABS alloy and its preparation, and low-odor field, to achieve the effect of simple preparation process, low cost and low odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] Preparation of jellyfish pellets:

[0046]Fully mix high-melt-strength polypropylene with different melt strengths and mineral fillers (talc powder, calcium carbonate or barium sulfate) according to the ratio shown in Table 1, extrude strip-shaped polypropylene in an extruder, and then Shred it into polypropylene pre-expanded granules; use water as a foaming agent to foam the polypropylene pre-expanded granules to prepare expanded polypropylene with high melt strength; Polypropylene and water were mixed in a high-speed mixer for 5-10 minutes. By controlling the mixing time, jellyfish particles with the water content shown in Table 1 were prepared and released for use.

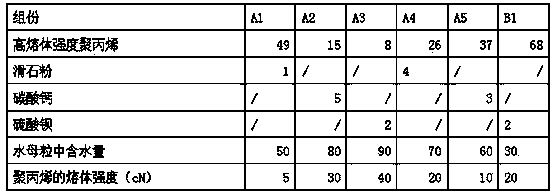

[0047] Table 1 The content of each component of jellyfish pellets (weight percent)

[0048]

Embodiment 1-5

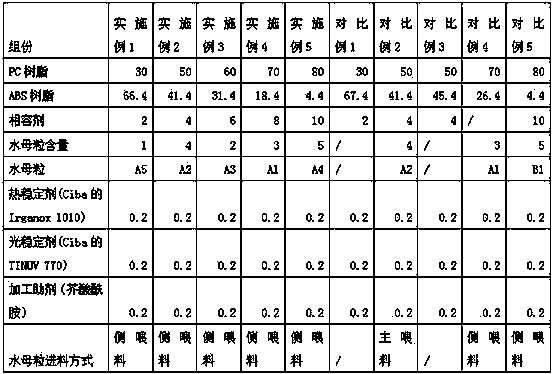

[0050] A kind of low odor, low emission PC / ABS alloy, its raw material formula is as shown in table 3, and its preparation method comprises the following steps:

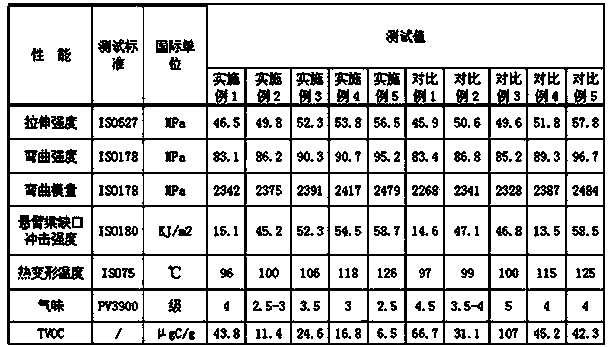

[0051] Weigh each component according to the weight percentage, mix in the high mixer for 1-3min; mix evenly to obtain the premix; put the premix in the main feeding port of the twin-screw extruder, Add jellyfish pellets, melt and extrude, then granulate and cool to obtain PC / ABS alloy. Determination of its performance, odor and volatile content, the specific data are listed in Table 4.

Embodiment 5

[0080] Comparing Example 5 with Comparative Example 5, the water content of jellyfish pellets in Comparative Example 5 is relatively low, and the prepared PC / ABS alloy has poor odor and high volatile matter content.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com