Reinforced flame retardant polyester with high molding rate and fluidity and production method thereof

A flame-retardant polyester and high-fluidity technology, which is applied in the field of flame-retardant polyester and its production, can solve the problems of short injection molding cycle, flame-retardant polyester material does not have fluidity and mold release ability, and achieves high mold release efficiency, Excellent mold release effect, high uniformity of toughness and fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

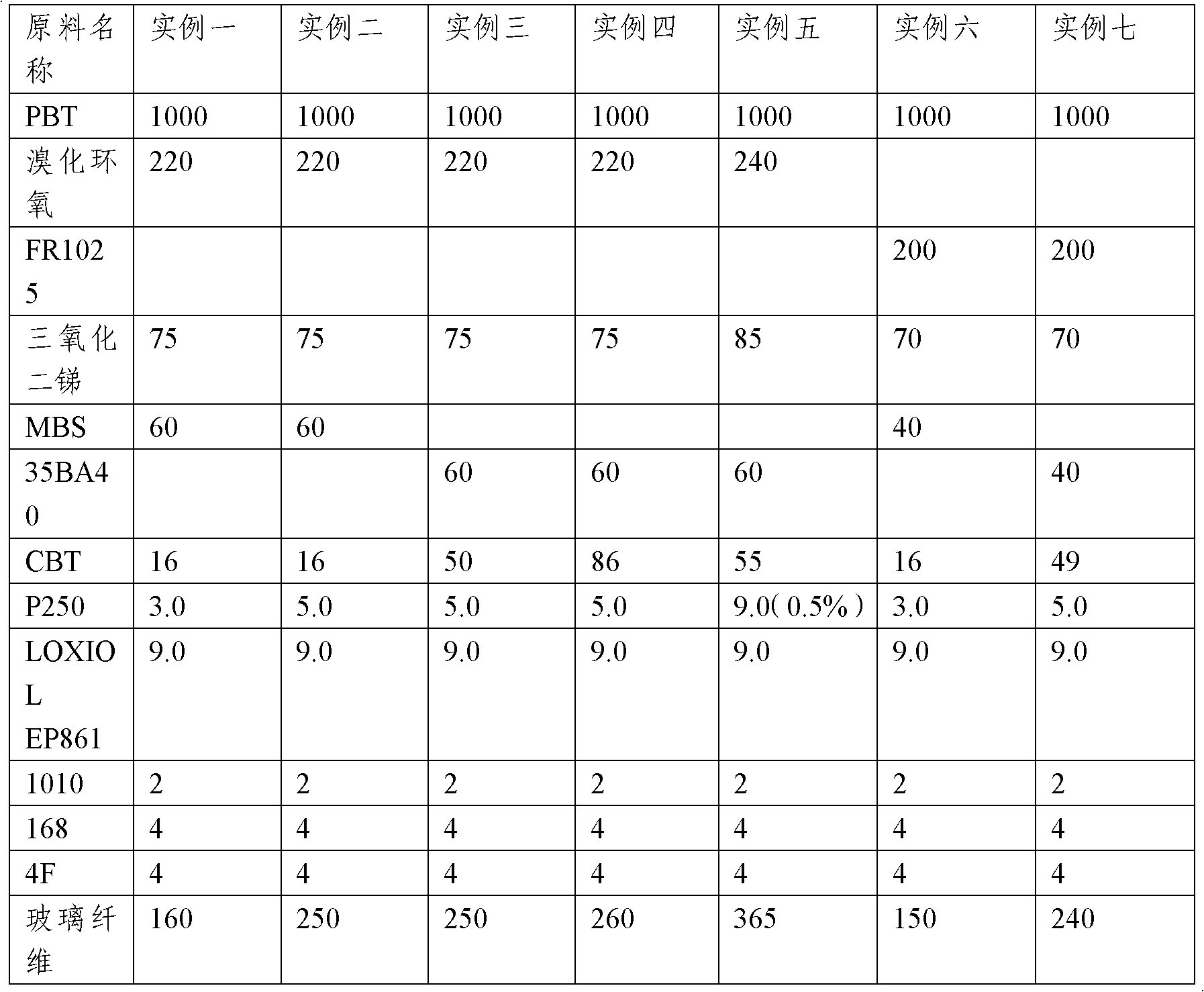

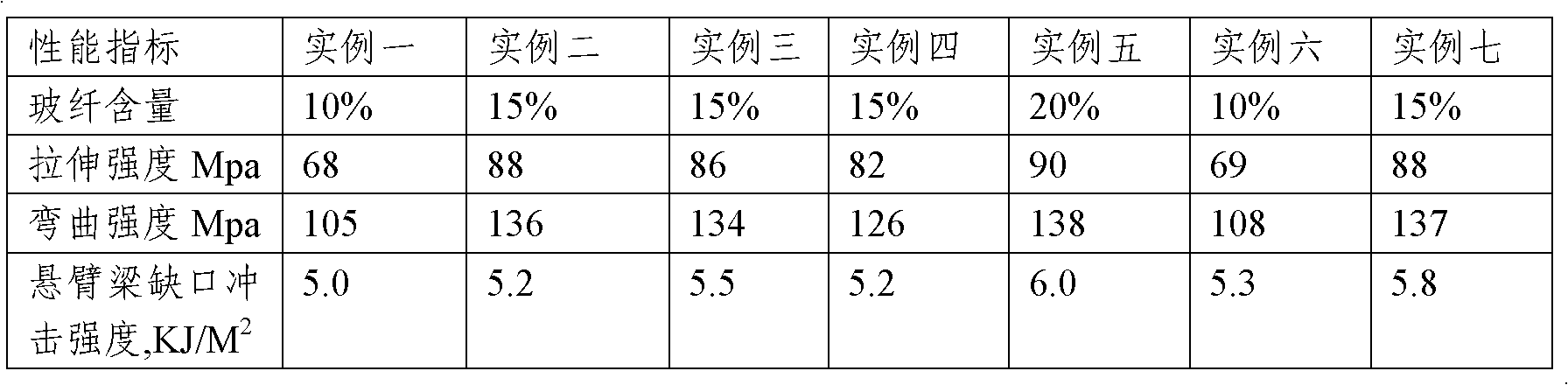

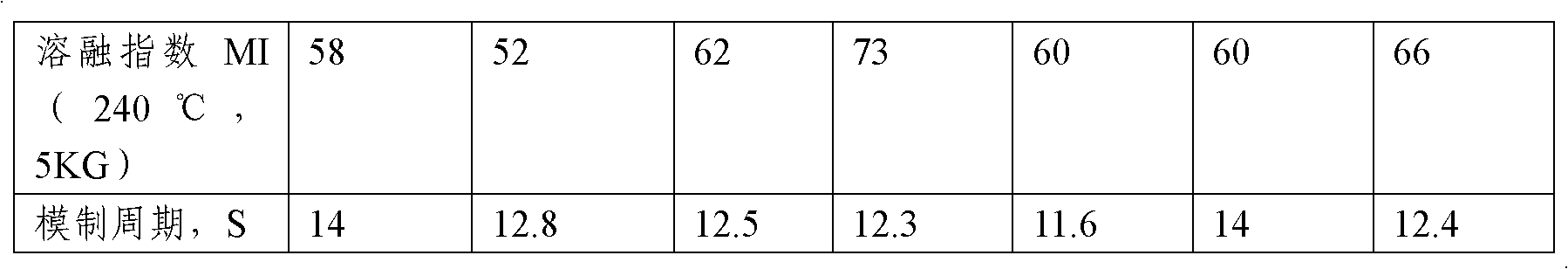

Examples

example 1、15、30

[0072] 0.1-30 parts of low-viscosity cyclic polyester (Example 1, 15, 30)

example 1

[0073] Antioxidant 0.1-5.0 parts (Example 1, 3, 5)

[0074] Nucleating agent 0.1-2.0 parts (for example 0.2, 1, 2)

[0075] Lubricant 0.2-8.0 parts (eg 0.5, 5, 8)

example 1、80、150

[0077] Other additives 0-10.0 parts (Example 1, 5, 10).

[0078] Described semi-crystalline thermoplastic polyester is polybutylene terephthalate, polytrimethylene terephthalate, polyethylene terephthalate, polyethylene terephthalate-1,4-cyclohexyl One of alkane dimethyl esters;

[0079] The main flame retardant is brominated epoxy, decabromodiphenylethane, brominated polycarbonate, brominated polyphenylene, polybrominated styrene, three-(tribromophenoxy)-triazine, polybrominated One or more of pentabromobenzyl esters and phosphorus (phosphine) nitrogen flame retardants;

[0080] The flame retardant synergist is one or more of antimony trioxide, sodium antimonate, and antimony pentoxide;

[0081] The toughening agent is one or more of rubber elastomers, core-shell impact modifiers, binary or ternary olefin copolymers, and olefin graft-modified copolymers;

[0082] Described low-viscosity cyclic polyester is cyclobutylene terephthalate resin;

[0083] The antioxidant includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com