Multicomponent alloy co-permeation anticorrosive coating on surface of steel and co-permeation method thereof

A technology of anti-corrosion layer and steel, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problem of no zinc-nickel light rare earth multi-element alloy, etc., and achieve strong corrosion resistance, high cost performance, and anti-corrosion performance excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

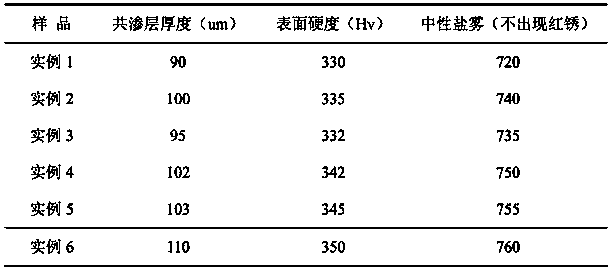

[0025] 100g zinc powder, 10g nickel powder, 2.5g La 2 o 3 , 2.5g Ce 2 o 3 Mix evenly to prepare multi-element alloy powder. Mix the multi-element alloy powder and 200g of quartz sand with a particle size of 80 mesh evenly and place it in the co-infiltration furnace for heating at 180°C for 2 hours. After cooling down to 60°C, remove it from the co-infiltration furnace.

[0026] The pretreated mixture, 0.2g NH 4 Add Cl and clean steel parts into the co-infiltration furnace, co-infiltrate at 400°C for 2 hours, and control the pressure at 0.1MPa to form a multi-component alloy co-infiltration layer with a certain thickness and excellent anti-corrosion performance on the surface of the metal substrate. Its main properties The results are shown in Table 1.

Embodiment 2

[0028] 100g zinc powder, 10g nickel powder, 2.5g La 2 o 3 , 2.5g Nd 2 o 3 Mix evenly to prepare multi-element alloy powder. Mix the multi-element alloy powder and 200g of quartz sand with a particle size of 80 mesh evenly and place it in the co-infiltration furnace for heating at 180°C for 2 hours. After cooling down to 60°C, remove it from the co-infiltration furnace.

[0029] The pretreated mixture, 0.2g NH 4 Add Cl and clean steel parts into the co-infiltration furnace, co-infiltrate at 400°C for 2 hours, and control the pressure at 0.1MPa to form a multi-component alloy co-infiltration layer with a certain thickness and excellent anti-corrosion performance on the surface of the metal substrate. Its main properties The results are shown in Table 1.

Embodiment 3

[0031] 100g zinc powder, 15g nickel powder, 2.5g Ce 2 o 3 , 2.5g Nd 2 o 3 Mix evenly to prepare multi-element alloy powder. Mix the multi-element alloy powder and 200g of quartz sand with a particle size of 80 mesh evenly and place it in the co-infiltration furnace for heating at 200°C for 2 hours. After cooling down to 60°C, remove it from the co-infiltration furnace.

[0032] The pretreated mixture, 0.2g NH 4 Add Cl and clean steel parts into the co-infiltration furnace, co-infiltrate at 400°C for 2 hours, and control the pressure at 0.1MPa to form a multi-component alloy co-infiltration layer with a certain thickness and excellent anti-corrosion performance on the surface of the metal substrate. Its main properties The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com