Antibacterial plastic master batch, and preparation method and antibacterial plastic thereof

A technology of antibacterial plastics and masterbatches, applied in the field of polymer composite materials, can solve the problems of low decomposition temperature of organic antibacterial agents, large particle size of inorganic antibacterial agents, high decomposition possibility, etc., and achieve simple process, good temperature resistance, Good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

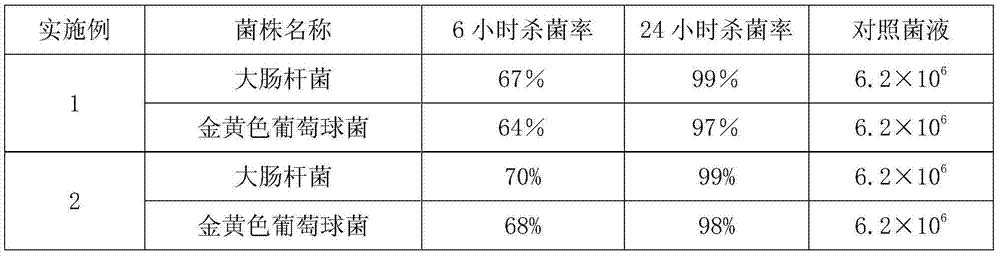

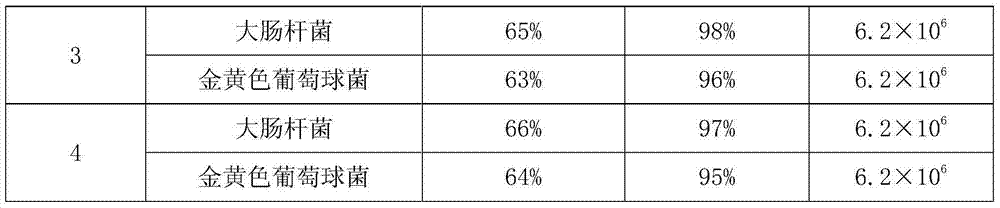

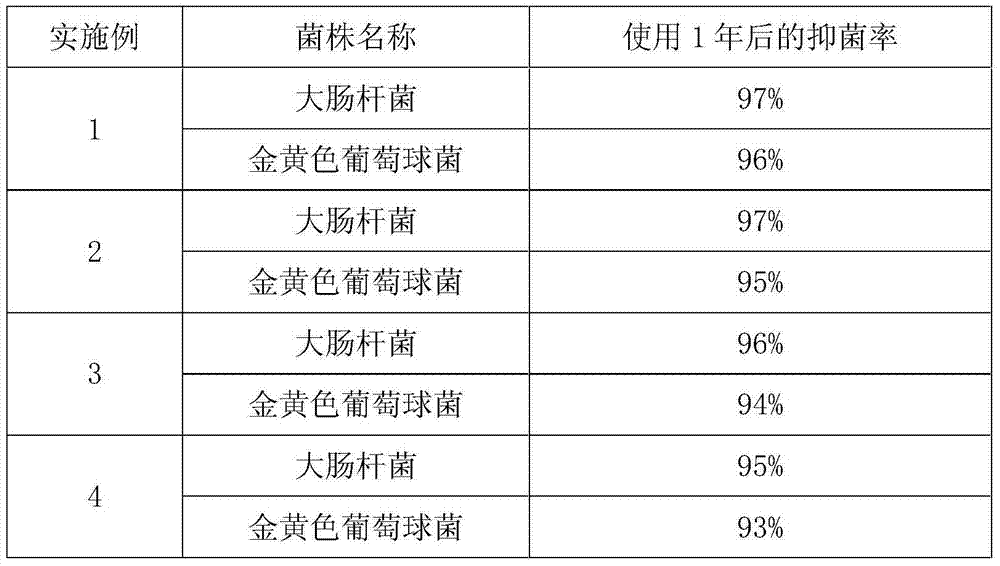

Examples

Embodiment 1

[0023] An antibacterial plastic masterbatch, the raw material components and their mass parts are: 1 part of coupling agent, 1 part of dispersant, 5 parts of polyethylene wax, 65 parts of nano-titanium dioxide antibacterial agent, and 28 parts of plastic resin.

[0024] The coupling agent is a high-efficiency monoalkoxy fatty acid titanate coupling agent, the manufacturer is Chengdu Tongli Auxiliary Co., Ltd., specification 901;

[0025] The dispersant is a grafted EBA dispersant, the manufacturer is Suzhou Xingtai Photochemical Auxiliary Co., Ltd., and the specification is TAS-2A;

[0026] The polyethylene wax manufacturer is Shanghai Jinshan Xingxing Plastic Co., Ltd., and the specification is WE-3 type;

[0027] The nano-titanium dioxide antibacterial agent is anatase nano-titanium dioxide with an average particle size of 10±5nm, and the manufacturer is Hangzhou Wanjing New Material Co., Ltd., the specification is VK-TA03;

[0028] The plastic resin is polypropylene plasti...

Embodiment 2

[0038] An antibacterial plastic masterbatch, the raw material components and their mass parts are: 0.3 parts of coupling agent, 5 parts of dispersing agent, 2 parts of polyethylene wax, 52 parts of nano-titanium dioxide antibacterial agent, and 40 parts of plastic resin.

[0039] The coupling agent is a high-efficiency monoalkoxy fatty acid titanate coupling agent, the manufacturer is Chengdu Tongli Auxiliary Co., Ltd., specification 901;

[0040] The dispersant is a grafted EBA dispersant, the manufacturer is Suzhou Xingtai Photochemical Auxiliary Co., Ltd., and the specification is TAS-2A;

[0041] The polyethylene wax manufacturer is Shanghai Jinshan Xingxing Plastic Co., Ltd., and the specification is WE-3 type;

[0042] The nano-titanium dioxide antibacterial agent is anatase nano-titanium dioxide with an average particle size of 20±10nm, the manufacturer is Hangzhou Wanjing New Material Co., Ltd., and the specification is VK-TA10;

[0043] The plastic resin is polyethyl...

Embodiment 3

[0053] An antibacterial plastic masterbatch, the raw material components and their mass parts are: 5 parts of coupling agent, 0.1 part of dispersant, 8 parts of polyethylene wax, 60 parts of nano-titanium dioxide antibacterial agent, and 37 parts of plastic resin.

[0054] The coupling agent is a high-efficiency monoalkoxy fatty acid titanate coupling agent, the manufacturer is Chengdu Tongli Auxiliary Co., Ltd., specification 901;

[0055] The dispersant is EBA dispersant, the manufacturer is Suzhou Xingtai Photochemical Auxiliary Co., Ltd., the specification is TAS-2A;

[0056] The polyethylene wax manufacturer is Shanghai Jinshan Xingxing Plastic Co., Ltd., and the specification is WE-3 type;

[0057] The nano-titanium dioxide antibacterial agent is anatase nano-titanium dioxide with an average particle size of 10±5nm, and the manufacturer is Hangzhou Wanjing New Material Co., Ltd., the specification is VK-TA03;

[0058] The plastic resin is polystyrene plastic resin, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com