A kind of medical composite adhesive and preparation method thereof

A composite adhesive, medical technology, applied in surgical adhesives, applications, medical science, etc., can solve the problems of short operation time, difficulty in control, slight tissue toxicity, and high brittleness of the adhesive layer, and achieve no toxic side effects, good biological phase, etc. The effect of capacitive, large adhesive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The preparation of embodiment 1 composite adhesive

[0018] Preparation of defatted soybean powder: after commercially available fresh soybeans are ground and passed through a 100-mesh sieve, the soybean powder under the sieve is taken for defatting. The specific method of degreasing: add 9mL of ether to each gram of soybean powder, shake in a constant temperature shaker at 27°C and 100r / min for 10h, take it out and let it stand for 25min, then discard the supernatant. The degreasing process was repeated twice. The defatted soybean flour was air-dried in a fume hood.

[0019] Preparation of soybean protein isolate: Add 10 mL of deionized water to each gram of defatted soybean powder, adjust the pH of the solution to 8.4, put it in a 45°C water bath, and extract for 35 minutes while stirring; centrifuge at 4°C and 3500×g After 30 min, the supernatant was taken as the extract. Take the extract and adjust the pH to 4.6 to precipitate the protein, centrifuge at 4°C and 3...

Embodiment 2

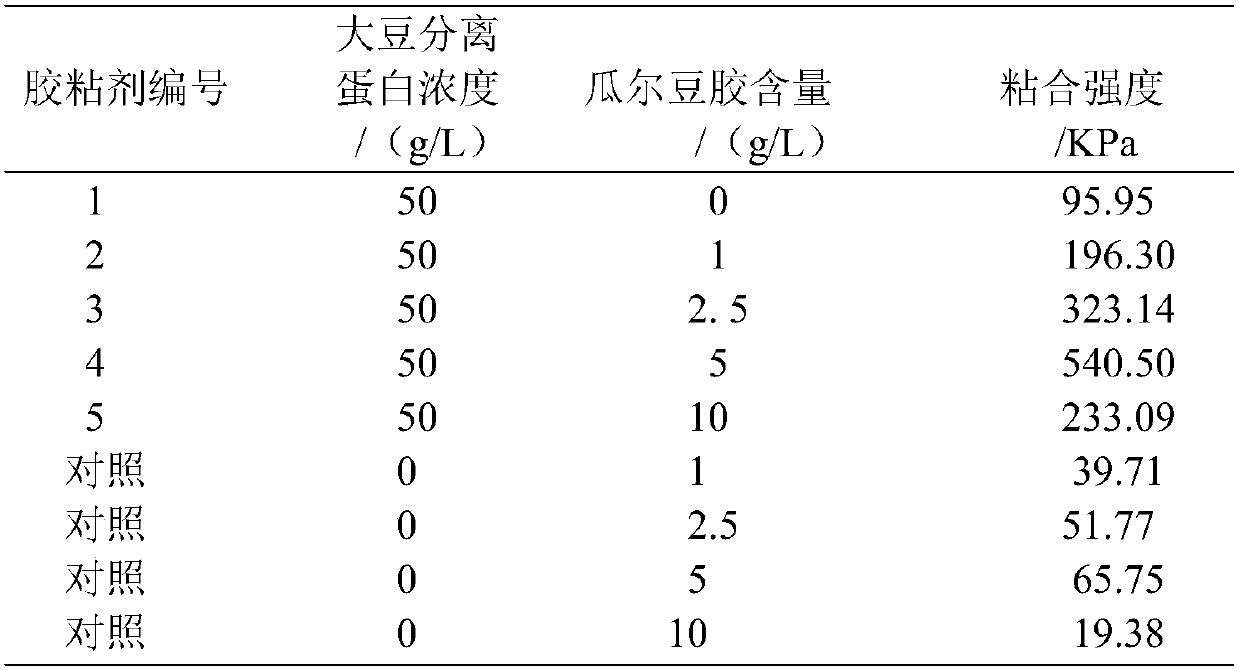

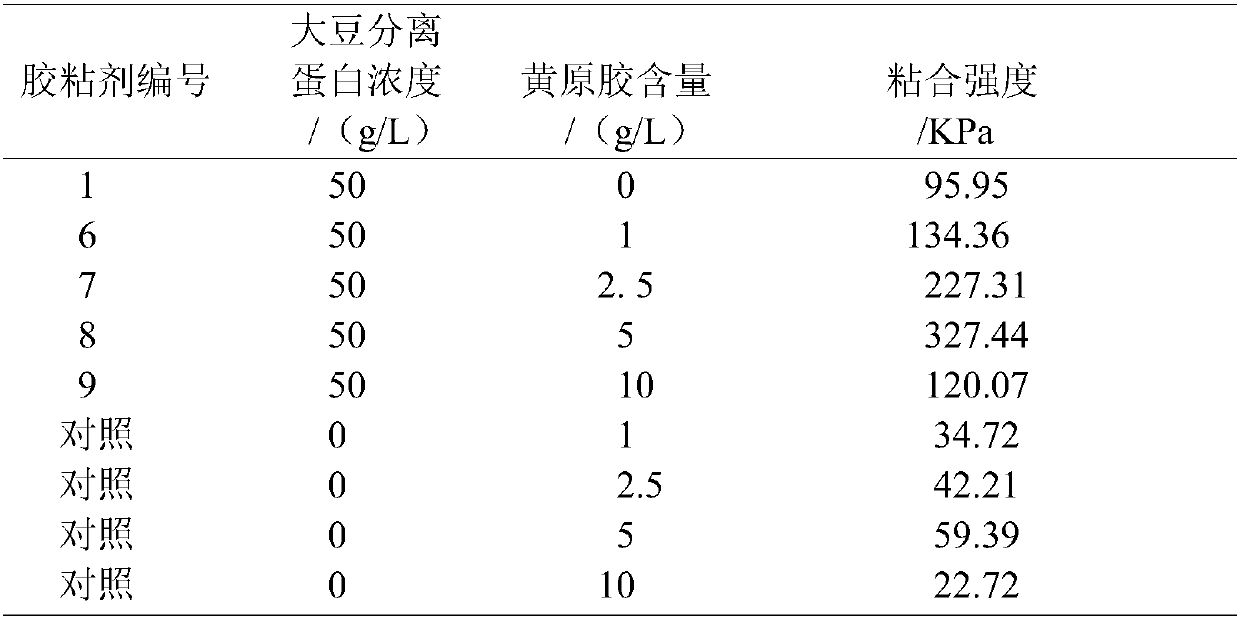

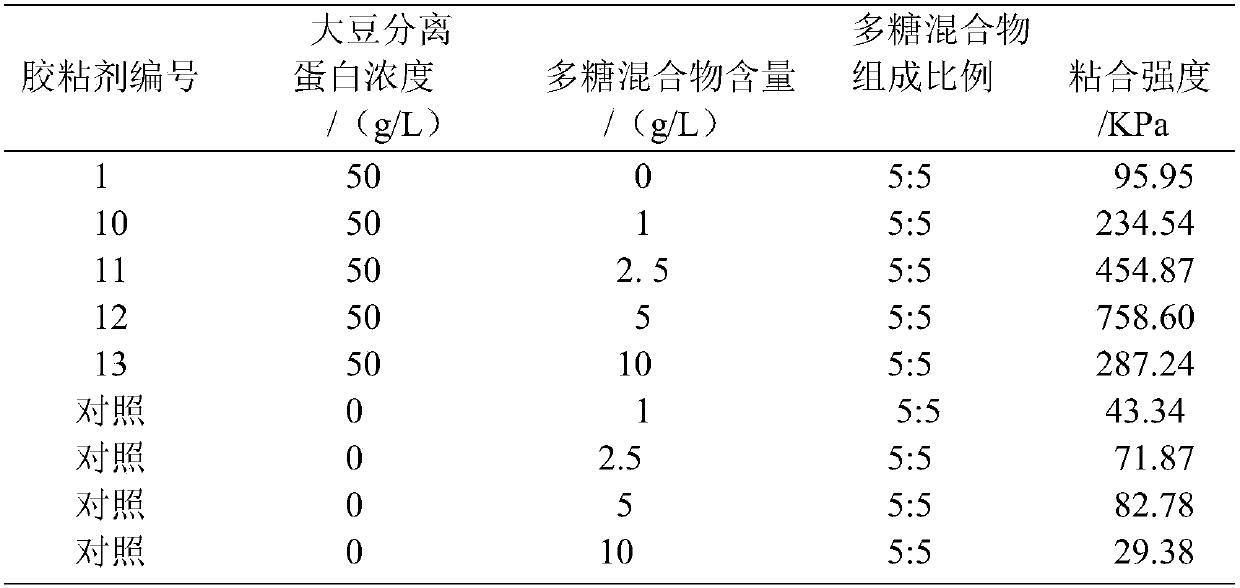

[0023] The bonding strength of embodiment 2 composite adhesives

[0024] This example tests the adhesive strength of each adhesive prepared in Example 1.

[0025] Bone-bonding model establishment: buy fresh pork fan bone, use T-504 medical electric drill, P-500-3 micro electric drill to saw it into bone slices with similar length and width. Soak fresh bone slices in pH 7.0, 0.01mol / L PBS buffer, shake in a constant temperature shaker at 37°C, 70r / min for 30min, repeat twice, remove blood and dry at room temperature for 2h, set aside. Divide two bone slices A and B with similar size and shape after treatment into one group. Apply the adhesive evenly on one side of bone pieces A and B at room temperature, the coating amount is about 0.5mg / cm 2 , the coating area is about 10mm×10mm, and then fully fix the bonding part with a rubber band. After standing for 20 minutes, soak the bound bone in saturated calcium chloride solution, take it out after curing for 5 minutes, and place t...

Embodiment 3

[0037] Example 3 Effects of Different Standing Times at Room Temperature on the Bonding Strength of Soy Protein Isolate-Guar Gum Composite Adhesive

[0038] Only change the standing time at room temperature in the preparation method of adhesive 4, and investigate the influence of standing at room temperature for 1h, 2h, 3h, and 4h on the adhesive strength of the adhesive. The composition, standing time at room temperature and bonding strength of each adhesive are shown in Table 5. The standing time at room temperature here refers to the standing time under the condition of 21°C-25°C.

[0039] Table 5 Adhesive formulation and its bond strength

[0040]

[0041] It can be seen from Table 5 that when the concentration of soybean protein isolate is 50 g / L, and the concentration of guar gum is 5 g / L, the maximum adhesive strength is 540.50 KPa after standing at room temperature for 2 hours during the preparation process. And the composite adhesives under different standing tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com