Organopolysiloxane composition, and curing method and application thereof

A polysiloxane and composition technology, applied in electrical components, semiconductor devices, circuits, etc., can solve the problems of low tensile strength, short operation time, affecting the service life of light-emitting diodes, etc., and achieve high tensile strength, The effect of high bonding strength and easy control of operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Add 50g of silicone resin to 100g of terminal vinyl silicone oil with a viscosity of 4000mPa·s (25°C) {its molecular structure is [(CH 3 ) 3 SiO 1 / 2 ] m [(CH 3 ) 2 (CH 2 =CH)SiO 1 / 2 ] n [SiO 4 / 2 ] z (Wherein (m+n) / z=1.0, z=25), the vinyl content is 0.4%}, mix uniformly and make base rubber compound.

[0046] Then add 0.005 g of 1,3-divinyl-1,1,3,3-tetramethyldisiloxane platinum complex and 1 g of vinyl tri-tertbutyl peroxide silane into 100 g of base rubber, and stir evenly Component (A) was prepared and used for later use.

[0047] Add 30g hydrogen-containing silicone oil (H%=1.0%) and 0.035g 1-ethynyl-1-cyclohexanol to 50g parts by mass of the base rubber, and mix uniformly at room temperature to prepare component (B), which is set aside.

[0048] Then component (A) and component (B) are mixed with each other according to the weight ratio of 1:1, heated and cured at 150° C. for 30 minutes to obtain the LED potting silicone rubber.

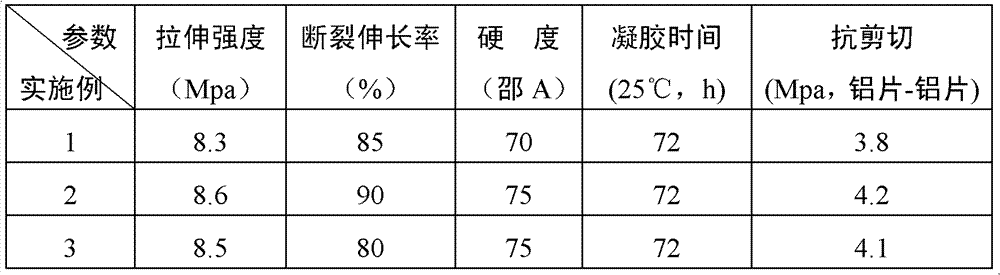

[0049] Table 1 shows th...

Embodiment 2

[0051] Add 60g of silicone resin to 100g of terminal vinyl silicone oil with a viscosity of 5000mPa·s (25°C) {its molecular structure is [(CH 3 ) 3 SiO 1 / 2 ] m [(CH 3 ) 2 (CH 2 =CH)SiO 1 / 2 ] n [SiO 4 / 2 ] z (wherein (m+n) / z=0.7, z=30) the vinyl content is 0.36%}, mix evenly to make the base rubber.

[0052] Then add 0.005g of 1,3-divinyl-1,1,3,3-tetramethyldisiloxane platinum complex and 1g of vinyl tri-tertbutylperoxysilane to 100g of base rubber, and stir well Component (A) was prepared and used for later use.

[0053] Add 20g of hydrogen-containing silicone oil (H%=1.2%) and 0.04g of 1-ethynyl-1-cyclohexanol to 75g of base rubber, and mix uniformly at room temperature to prepare component (B), which is set aside.

[0054] Then component (A) and component (B) are mixed with each other according to the weight ratio of 1:1, heated and cured at 150° C. for 30 minutes to obtain the LED potting silicone rubber.

[0055] Table 1 shows the physical and mechanical propert...

Embodiment 3

[0057] Add 50g of silicone resin to 100g of vinyl silicone oil with a viscosity of 4000mPa·s (25°C) {its molecular structure is [(CH 3 ) 3 SiO 1 / 2 ] m [(CH 3 ) 2 (CH 2 =CH)SiO 1 / 2 ] n [SiO 4 / 2 ] z , where (m+n) / z=1.2, z=35) the vinyl content is 0.39%}, mix evenly to make the base compound.

[0058] Then add 0.005g bis(alkynyl) (1,5-cyclooctadiene) platinum complex in 100g base rubber compound, 1g vinyl trit-butyl peroxide silane, stir to obtain component (A), spare.

[0059] Add 20 g of polymethylhydrogen siloxane (H%=1.6%) and 0.04 g of 2-methyl-3-butyn-2-ol into 80 g of base rubber, and mix uniformly at room temperature to obtain a compound Point (B), spare.

[0060] Then component (A) and component (B) are mixed with each other according to the weight ratio of 1:1, heated and cured at 150° C. for 30 minutes to obtain the LED potting silicone rubber.

[0061] Table 1 shows the physical and mechanical properties of the above-mentioned LED potting silicone rubber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molar mass | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com