Tetraethylorthosilicate inorganic high-temperature-resistant coating and preparation method thereof

A technology of ethyl orthosilicate, inorganic high temperature resistance, applied in anti-corrosion coatings, coatings, etc., can solve the problems of passive film damage on metal surfaces, corrosion of metal facilities, etc., and achieve the effect of reducing the tendency of cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

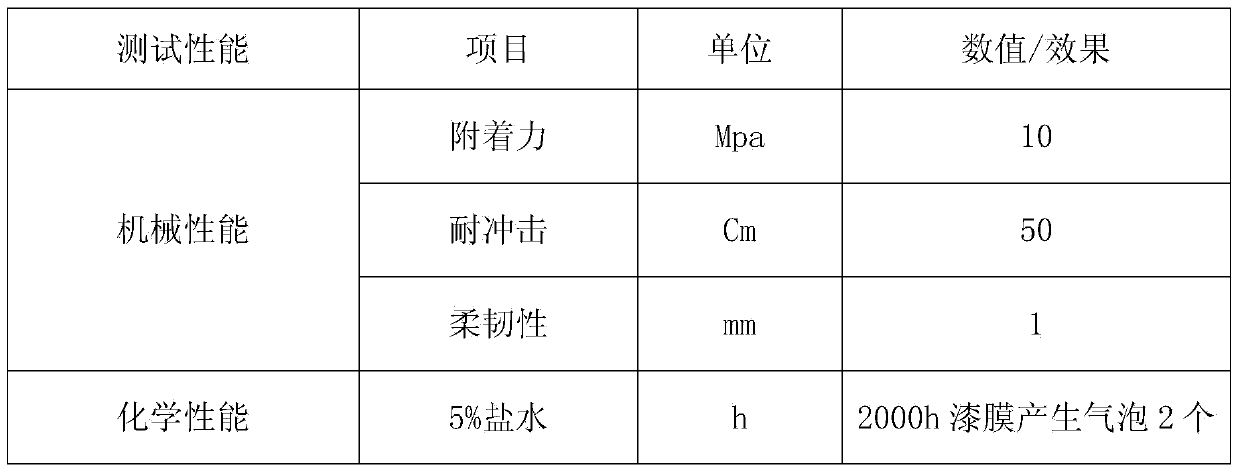

Embodiment 1

[0031] A tetraethyl orthosilicate inorganic high-temperature-resistant coating provided in this example has the following mass percentages of its components: 28% orthoethyl silicate; heat-resistant pigments and fillers: 35%; additives: 3%, dimethyl Formamide: 15% of which:

[0032] Heat-resistant pigments and fillers include:

[0033] Nano silicon dioxide, barrier type functional filler and aluminum powder and the mass ratio of nano silicon dioxide, barrier type functional filler and aluminum powder is 1.5:1:1;

[0034] Barrier functional fillers include the following components in parts by mass:

[0035] Hollow glass microspheres: 3 parts, graphite: 12 parts, black silicon carbide: 2444 parts, fine-grained alumina: 26 parts, molybdenum disulfide: 6 parts, zinc oxide: 3 parts, talcum powder: 4 parts;

[0036] Auxiliaries include the following components in parts by mass:

[0037] Dispersing agent: 12 parts, wetting agent: 3 parts, curing agent: 26 parts, matting agent: 3 pa...

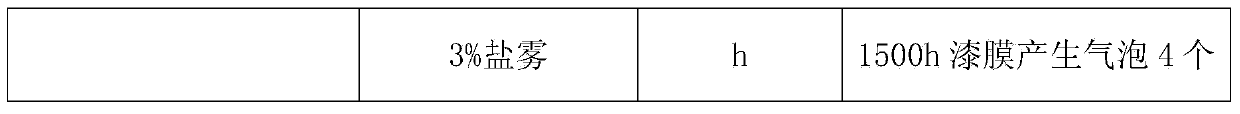

Embodiment 2

[0043]A tetraethyl orthosilicate inorganic high-temperature-resistant coating provided in this example has the following percentages by mass of each component: tetraethyl orthosilicate 32%; heat-resistant pigments and fillers: 49%; additives: 3%, two Methylformamide: 16%, heat-resistant pigments and fillers are nano-silica and aluminum powder, the mass ratio of nano-silica and aluminum powder is 1.5:1, wherein,

[0044] Heat-resistant pigments and fillers include:

[0045] Nano silicon dioxide, barrier type functional filler and aluminum powder and the mass ratio of nano silicon dioxide, barrier type functional filler and aluminum powder is 1.5:1:1;

[0046] Barrier functional fillers include the following components in parts by mass:

[0047] Hollow glass microspheres: 4 parts, graphite: 11 parts, black silicon carbide: 26 parts, fine-grained alumina: 26 parts, molybdenum disulfide: 6 parts, zinc oxide: 4 parts, talcum powder: 4 parts;

[0048] Auxiliaries include the follo...

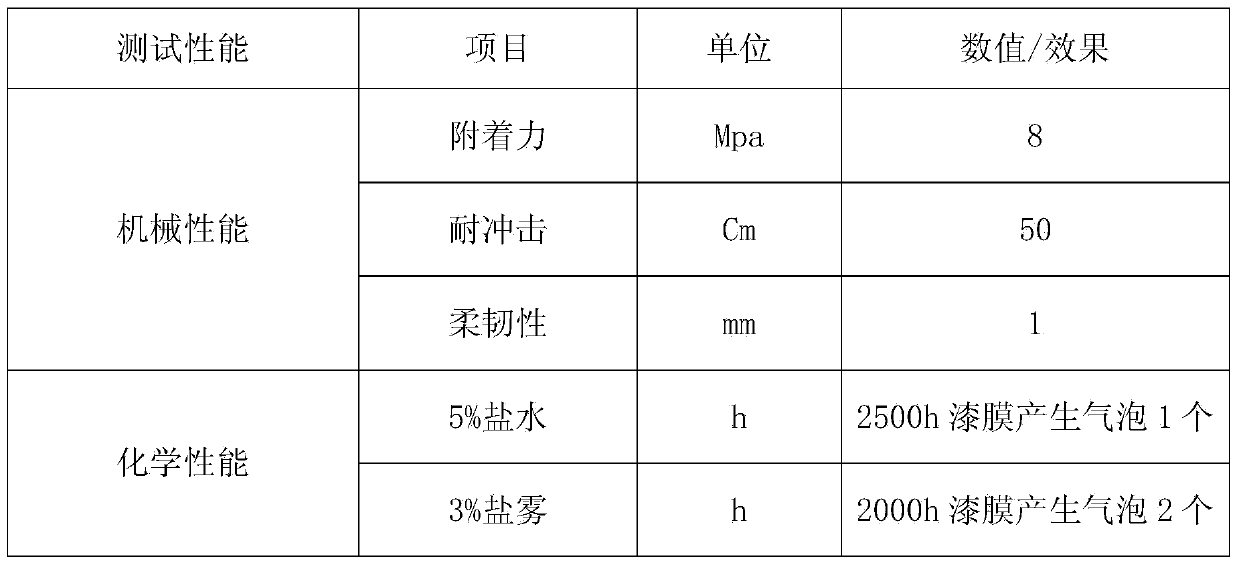

Embodiment 3

[0055] The preparation method of a kind of tetraethyl orthosilicate inorganic high-temperature-resistant coating provided by the present embodiment comprises the following steps:

[0056] (1) Prepare the base material by hydrolyzing tetraethyl orthosilicate. The specific operation is as follows: adjust the temperature of the water bath to 45°C, stir and mix 32% by mass of tetraethyl orthosilicate and the silane coupling agent evenly, and the silane The mass ratio of coupling agent to tetraethyl orthosilicate is 1:15, then slowly add a mixture of water, ethanol and hydrochloric acid dropwise, heat and stir in a water bath for 2 hours, wherein the mass of water is half of the mass of tetraethyl orthosilicate One, the quality of ethanol is 1 / 4th of tetraethyl orthosilicate quality, and the mass ratio of the quality of hydrochloric acid and tetraethyl orthosilicate is 0.6:1;

[0057] (2) After mixing 32% by mass of tetraethyl orthosilicate hydrolyzed base material and 45% by mass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com