Three-dimension laser fine machining system and method for crisp and hard materials

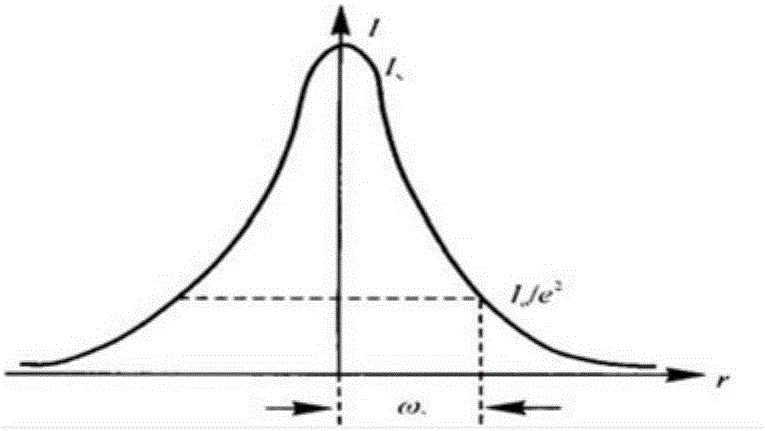

A three-dimensional laser and fine processing technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult popularization and application, low average laser power, high equipment cost, etc., to avoid heat accumulation and improve spatial uniformity , The effect of uniform focal spot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0051] The three-dimensional laser fine processing system for brittle and hard materials disclosed in the present invention includes a computer control system, a three-dimensional dynamic focusing scanning system, and a pulse laser;

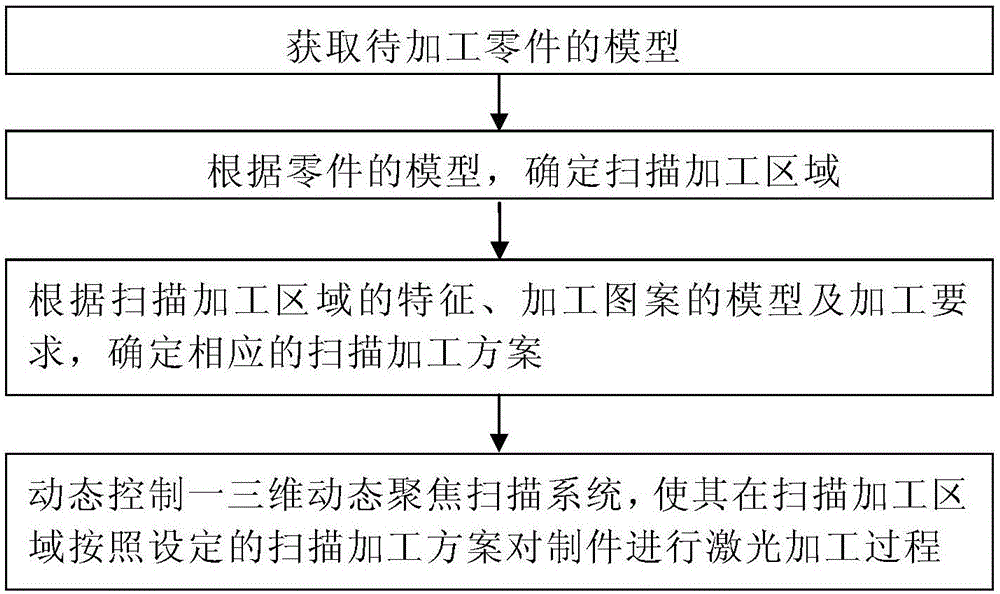

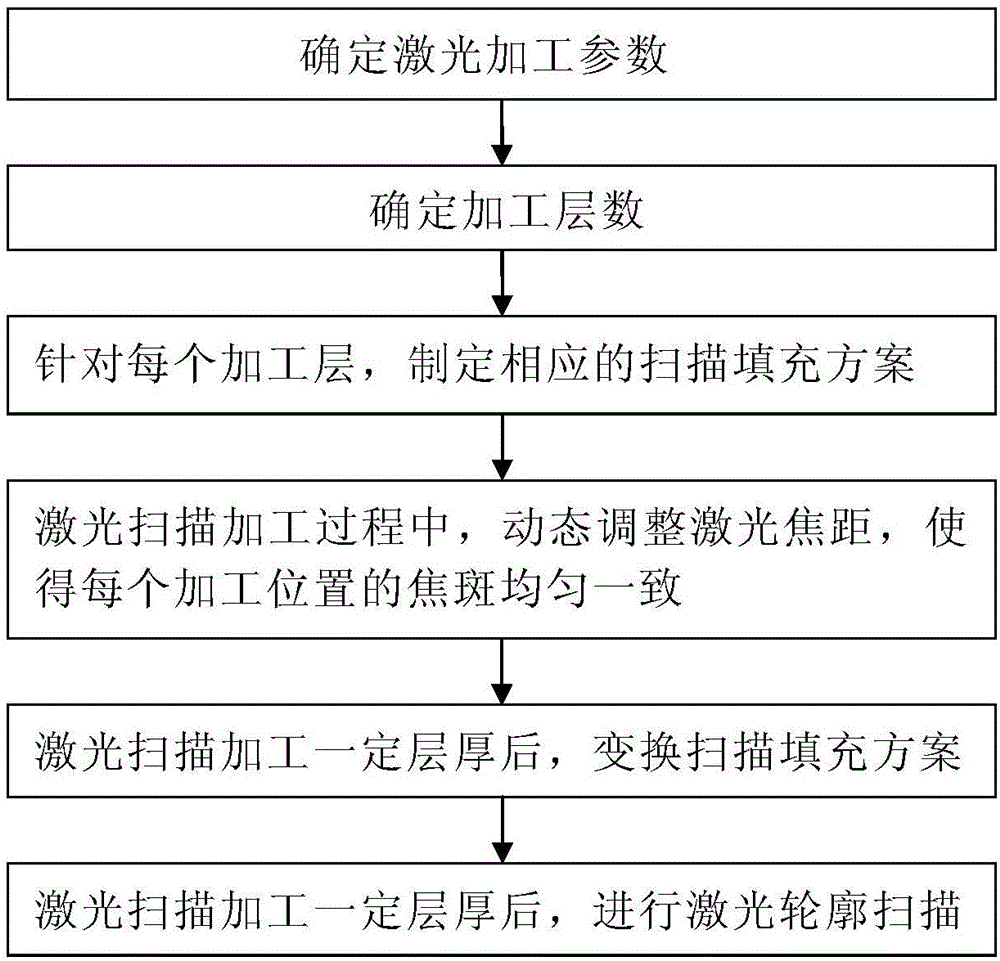

[0052] The computer control system is used to input the model of the part to be processed and the model of the processing pattern, determine the scanning processing area on the workpiece according to the model of the part, and determine the scanning processing according to the characteristics of the scanning processing area, the model of the processing pattern and the processing requirements Program;

[0053] The three-dimensional dynamic focusing scanning system is used to perform laser processing on the scanning processing area on the surface of the workpiece according to the set scanning processing plan. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spot diameter | aaaaa | aaaaa |

| Pulse width | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com