A drill pipe joint

A technology for drill pipe joints and drill pipes, which is applied in the direction of drill pipes, drill pipes, drilling equipment, etc., and can solve problems such as difficulty in ensuring the sealing effect, falling of drill pipes or bits into holes, and affecting the service life of threaded joints. Reliable, uniform cracking results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

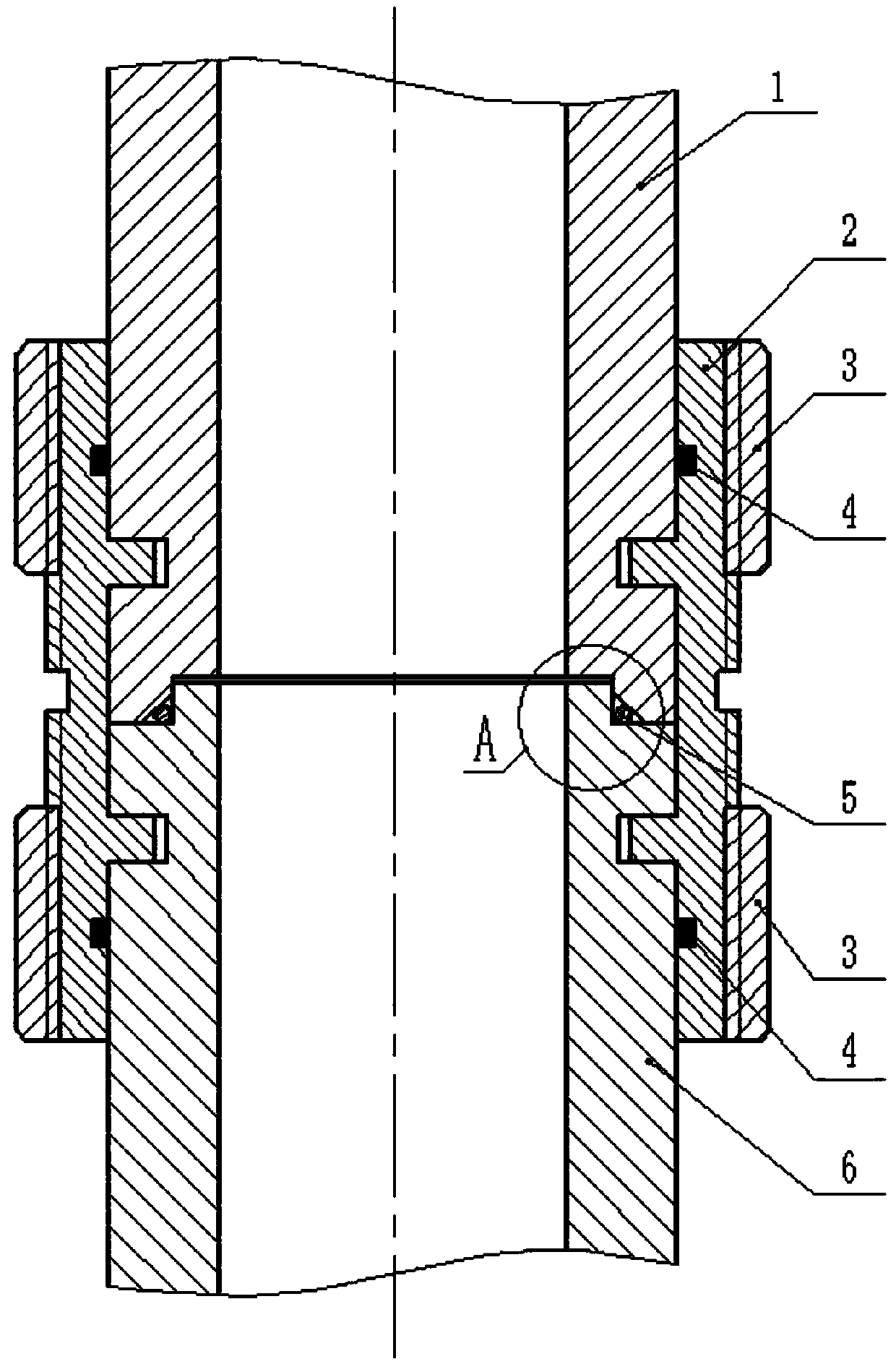

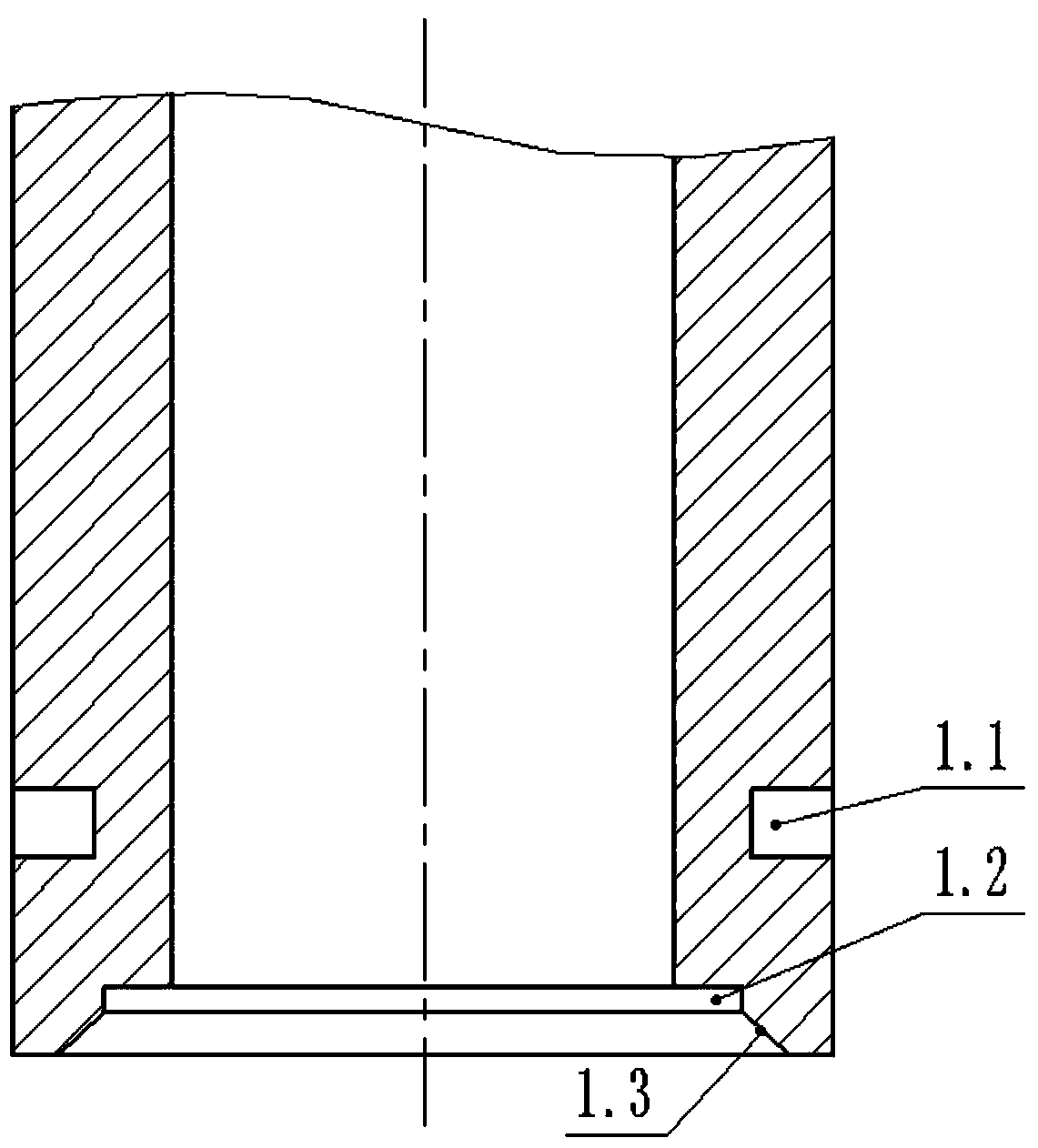

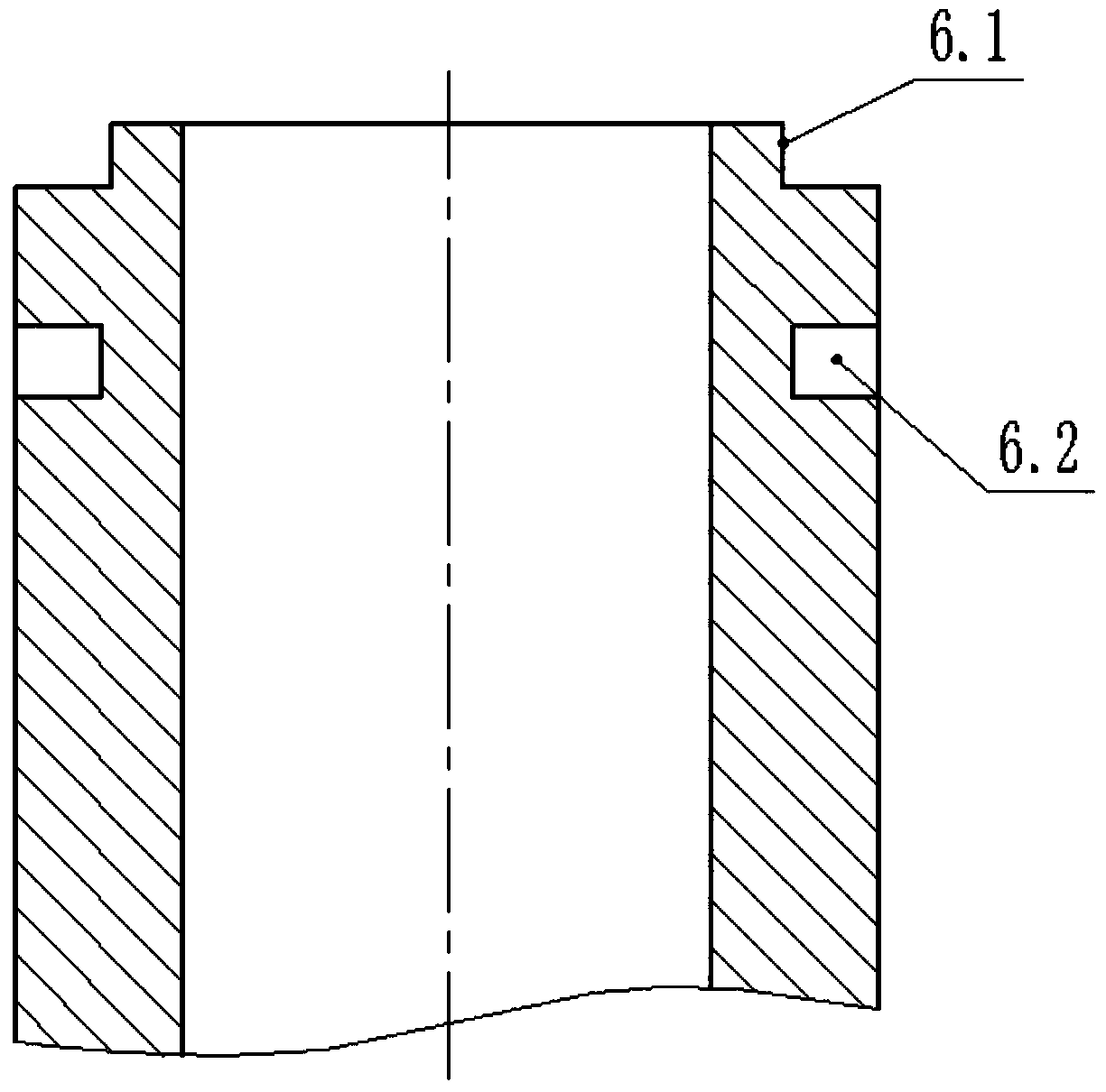

[0035] Such as Figure 1-6 As shown, a drill pipe joint provided by the present invention includes a male drill pipe 1, a female drill pipe 6, a snap ring 2 and a nut 3, the lower end surface of the male drill pipe 1 is provided with an inner stop 1.2, and the inner The opening of the spigot 1.2 is provided with a chamfer 1.3, the outer wall of the male drill rod 1 is provided with a groove 1.1, and the upper end surface of the female drill rod 6 is provided with a groove corresponding to the inner spigot 1.2 of the male drill rod. Matched outer stop 6.1, the peripheral outer wall of the female drill pipe 6 is provided with the same groove 6.2 as the male drill pipe groove 1.1, the snap ring 2 has a symmetrical structure up and down, and the snap ring 2 The outer wall of the circumference is provided with two external threads, and a tool relief groove 2.3 is provided between the two external threads, and the inner wall of the circumference of the snap ring 2 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com