Right-angle electrical connector

An electrical connector and connector technology, applied in the direction of connection, fixed connection, and components of the connection device, can solve the problems of poor welding, inconsistent welding, incomplete welding, etc., and achieve good welding results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

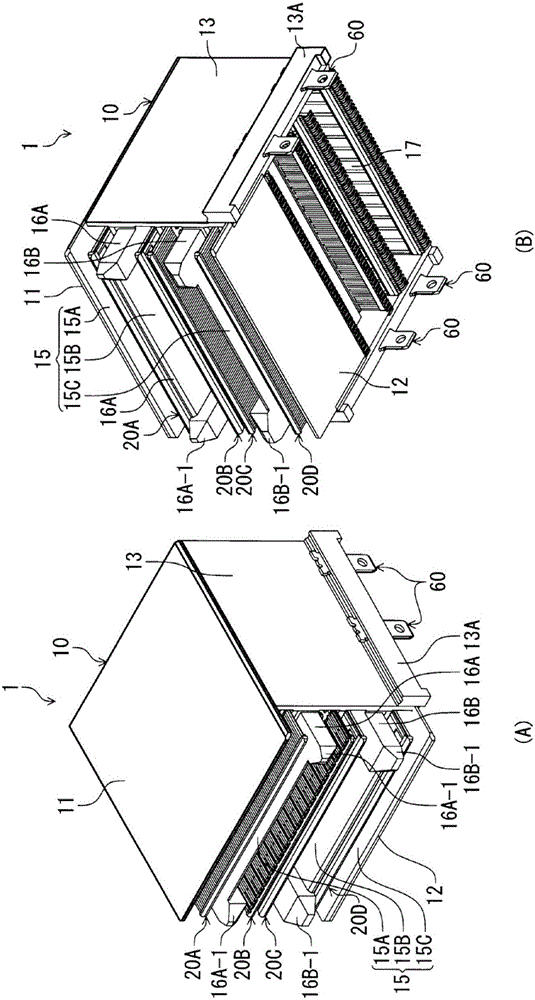

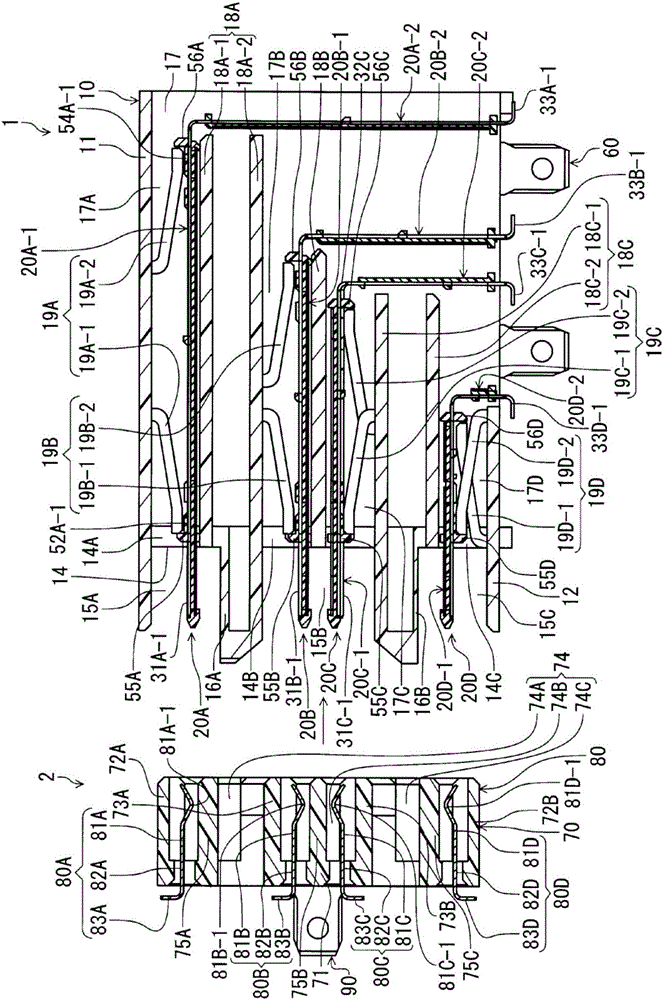

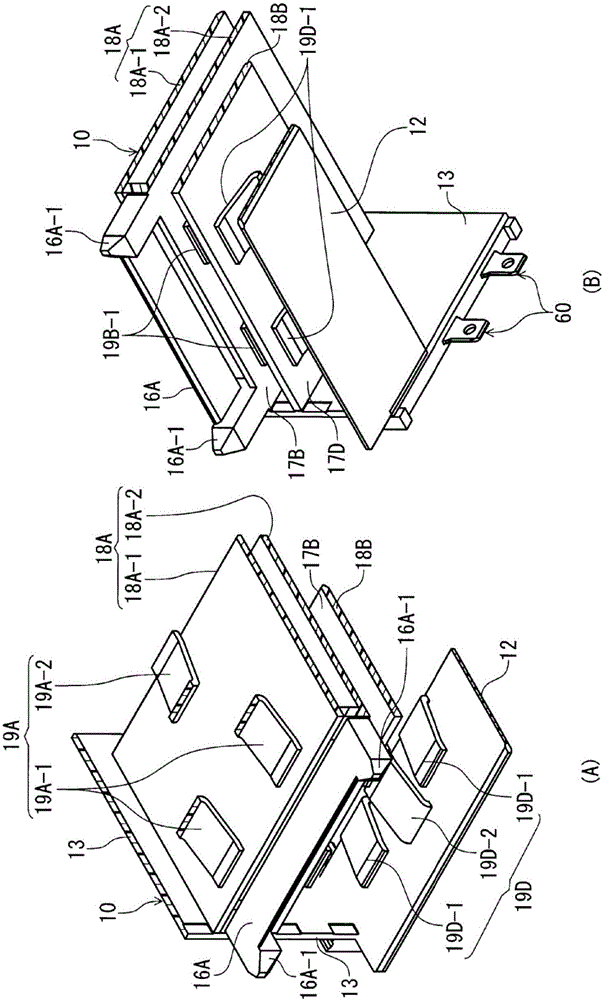

[0034] Hereinafter, embodiments of the present invention will be described based on the drawings.

[0035] figure 1 The electrical connectors of this embodiment shown in (A) and (B) are formed in a direction in which a mating connector is fitted and a connection portion soldered to a circuit board (not shown) is arranged in the direction of the circuit board. A so-called right-angle electrical connector (hereinafter referred to as "connector") in which the direction in which the legs of the terminals of the connecting portion extend is at right angles. figure 1 (A) is a perspective view showing the appearance of the connector 1 according to the present embodiment viewed obliquely from above, figure 1 (B) is a perspective view showing the appearance of the connector 1 viewed obliquely from below. figure 2 It is a cross-sectional view of the connector 1 on a plane perpendicular to the width direction of the connector, and shows a cross section of the position of the termin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com