Manufacturing method for integrated panel with thin-wall ultrahigh reinforcing rib

A technology of integral wall panels and manufacturing methods, which is applied in the field of manufacturing thin-wall integral wall panels, can solve problems such as the inability to manufacture thin-wall integral wall panels, and achieve simplification of size and structure, reduction of thickness or strength, and long life of molds. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

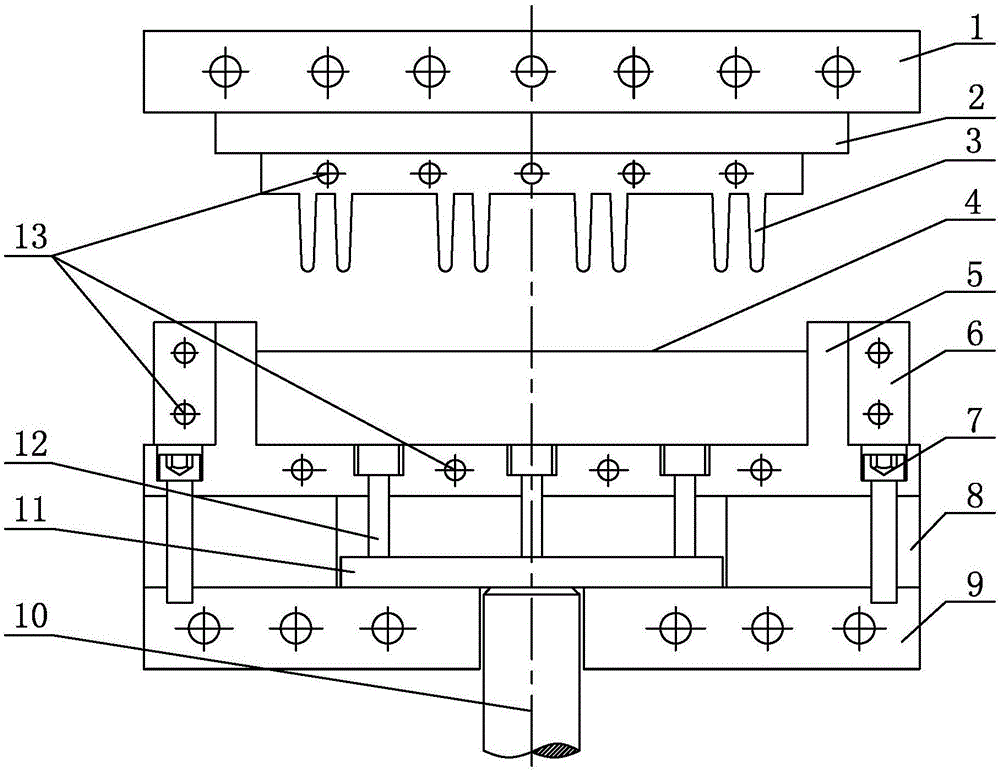

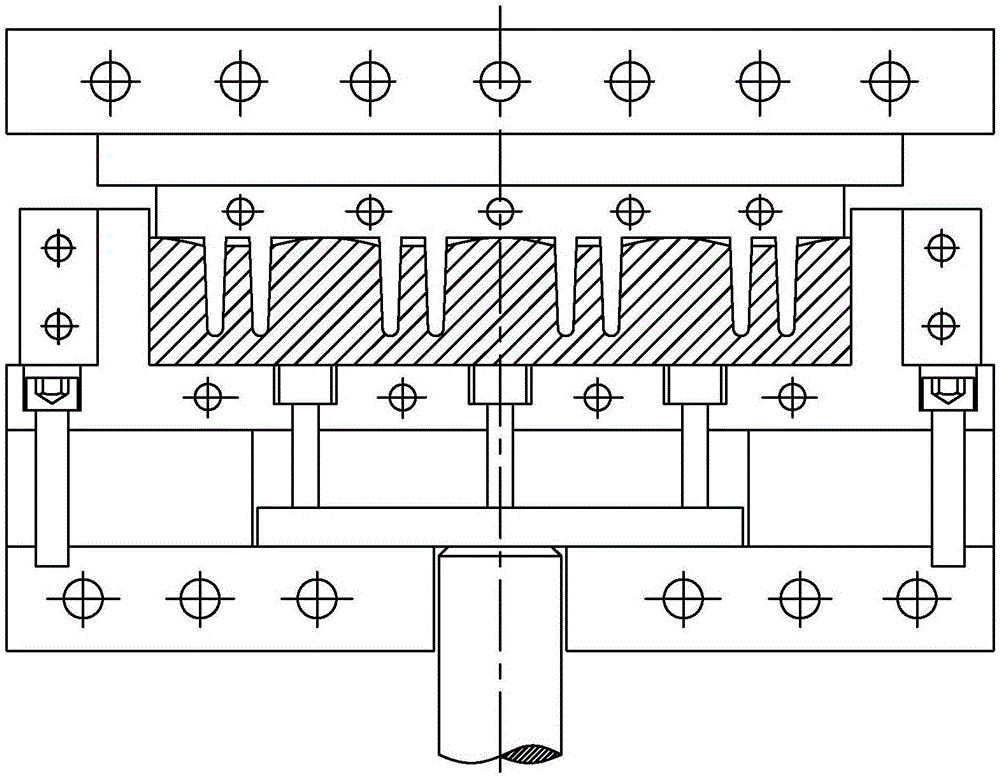

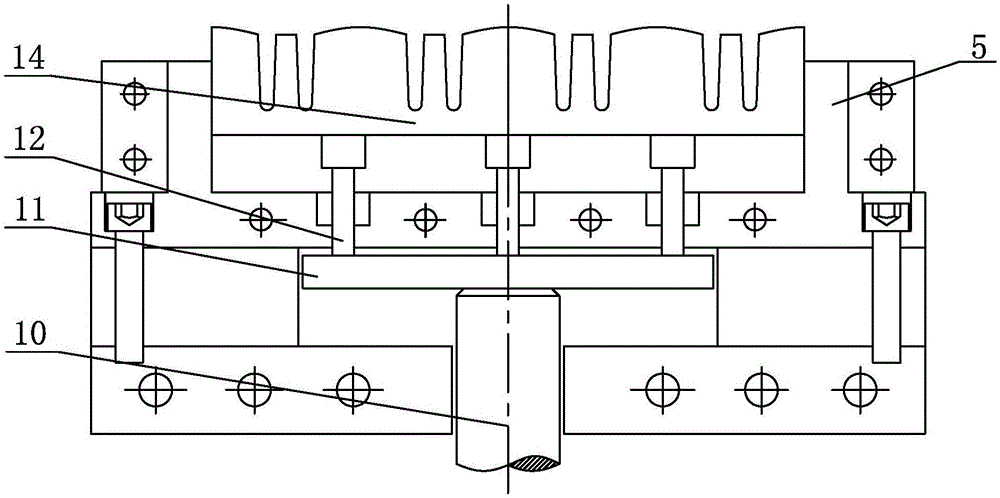

[0032] Specific implementation mode one: combine Figure 1-7 Illustrate, a kind of manufacturing method of the integral panel with thin-walled ultra-high reinforcing rib of this embodiment is realized according to the following steps:

[0033] Step 1, select the original plate with a certain thickness, and make the required smooth slab 4 by cutting and punching;

[0034] Step 2, preheating the blank, putting the slab 4 to be formed into a heating furnace and heating it to (0.5-0.7) Tm, and keeping it warm for a period of time to make the internal temperature of the blank uniform, and Tm is the melting point of the material;

[0035] Step 3, preheating and lubricating the mold, using the electromagnetic induction heating coil 13 and the intermediate heating plate 6 to heat the upper mold 3 and the lower mold 5, and when the upper mold 3 and the lower mold 5 reach the preset temperature, the upper mold 3 and the lower mold 5 are heated. Lubricant is sprayed on the cavity of the...

specific Embodiment approach 2

[0042] Specific implementation mode two: combination figure 1 Note that when the overall size of the thin-walled ultra-high ribs to be processed is small and the processing temperature is low (less than 700°C), the second step can be to place the slab 4 directly into the lower mold 5 and use electromagnetic induction heating The coil 13 and the middle heating plate 6 heat the upper mold 3 and the lower mold 5, and heat the slab 4 to a predetermined temperature through the heat conduction of the upper mold 3 and the lower mold 5. Others are the same as the first embodiment.

specific Embodiment approach 3

[0043] Specific implementation mode three: combination figure 1 , Figure 4 , Figure 6 and Figure 9 Explain that step 1 can cut off a small part of the upper mold cavity filling area ⑤ in the slab 4 through initial simple machining, and the machined grooved slab 20 after processing can be used as the initial slab for hot molding for hot state Molded. Others are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com