A core-shell structure al@ti-al 2 o 3 Phase change heat storage composite material and preparation method thereof

A core-shell structure, phase change heat storage technology, applied in the direction of heat exchange materials, chemical instruments and methods, metal processing equipment, etc., can solve the problem of large voids in the ceramic substrate, poor phase change heat storage cycle stability, and loss of phase change materials And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

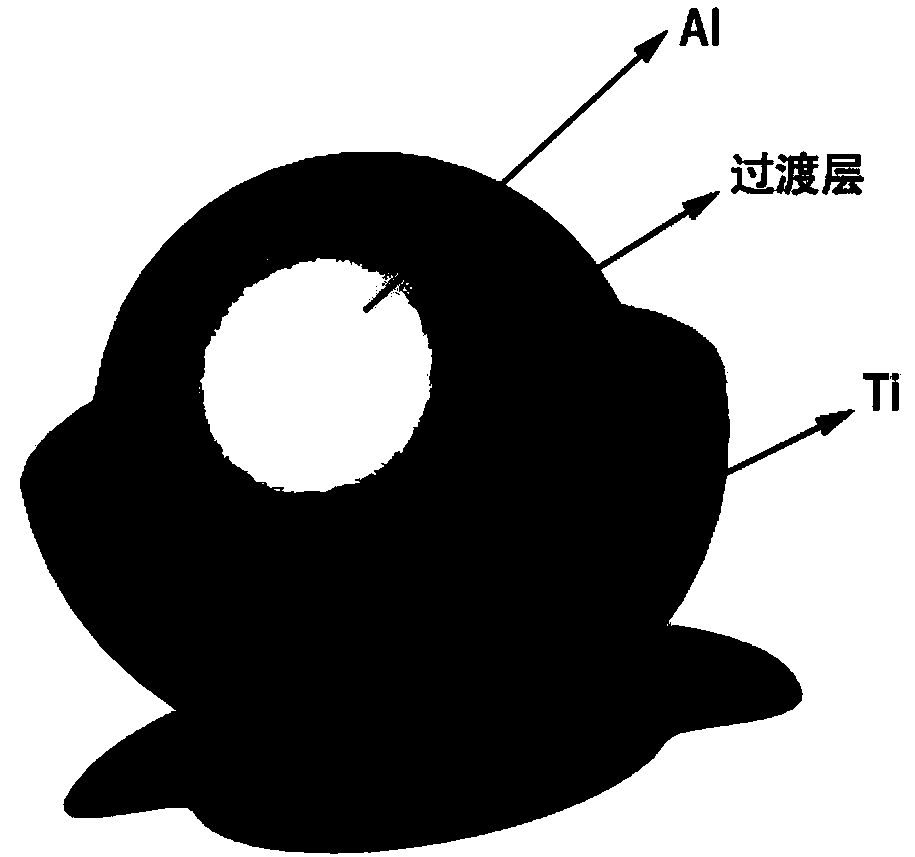

[0032] (1) Preparation of core-shell structure Al@Ti microsphere powder

[0033] Take 15g of titanium powder with a particle diameter of 325 mesh, and then take 5g of aluminum powder with a particle diameter of 50 mesh, and put them into a ball mill pot with 500g of stainless steel balls to evacuate (make the pressure drop below 0.1Pa), and put them in a planetary ball mill at 300r The rotation speed of / min is mixed in forward and reverse directions, rotate for 10 minutes and stop for 5 minutes, and the total time of ball milling is 20 hours, and mechanical alloying is carried out to obtain Al@Ti microsphere powder with core-shell structure.

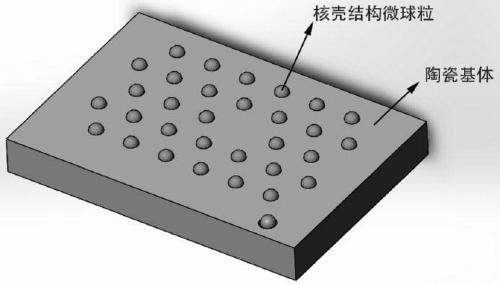

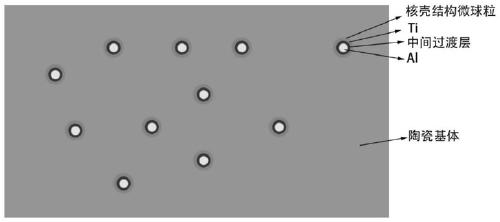

[0034] (2)Al@Ti-Al 2 o 3 Preparation of Phase Change Thermal Storage Composite Materials

[0035] Take 5 g of the core-shell structure Al@Ti microsphere powder prepared above and 40 g of Al 2 o 3 Proportioning of ceramic powder, put 500g stainless steel balls into the ball mill pot to evacuate (to reduce the pressure below 0.1Pa), and...

Embodiment example 2

[0037] (1) Preparation of core-shell structure Al@Ti microsphere powder

[0038] Take 15g of titanium powder with a diameter of 325 mesh, and then take 5g of aluminum powder with a diameter of 50 mesh, and put it into a ball mill pot with 500g of stainless steel balls to evacuate (make the pressure drop below 0.1Pa), and put it in a planetary ball mill at 300r / min Forward and reverse rotation of the mixing speed, rotate for 10 minutes and stop for 5 minutes, and the total time of ball milling is 20 hours to obtain the core-shell structure Al@Ti microsphere powder.

[0039] (2)Al@Ti-Al 2 o 3 Preparation of Phase Change Thermal Storage Composite Materials

[0040] Weigh 5 g of the above-prepared core-shell structure Al@Ti microsphere powder and 45 g of Al 2 o 3 Proportioning of ceramic powder, put 500g stainless steel balls into the ball mill tank to evacuate (to reduce the pressure to below 0.1Pa), and mix in the planetary ball mill at a speed of 145r / min in one direction, ...

Embodiment example 3

[0042] (1) Preparation of core-shell structure Al@Ti microsphere powder

[0043] Take 15g of titanium powder with a diameter of 325 mesh, and then take 6g of aluminum powder with a diameter of 50 mesh, and put it into a ball mill pot with 500g of stainless steel balls to evacuate (make the pressure drop below 0.1Pa), and put it in a planetary ball mill at 300r / min Forward and reverse rotation of the mixing speed, rotate for 10 minutes and stop for 5 minutes, and the total time of ball milling is 20 hours to obtain the core-shell structure Al@Ti microsphere powder.

[0044] (2)Al@Ti-Al 2 o 3 Preparation of Phase Change Thermal Storage Composite Materials

[0045] Weigh 5 g of the core-shell structure Al@Ti microsphere powder and 40 g of Al 2 o 3 Proportioning of ceramic powder, put 500g stainless steel balls into the ball mill tank to evacuate (to reduce the pressure to below 0.1Pa), and mix in the planetary ball mill at a speed of 145r / min in one direction, and the total t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com