Device and method for manufacturing panel with embossing on surface

A technology of embossing and panel parts, which is applied in the field of panel device devices, and can solve problems such as unsolvable problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to describe the structure and characteristics of the present invention in detail, the following preferred embodiments are given and illustrated in conjunction with the drawings as follows:

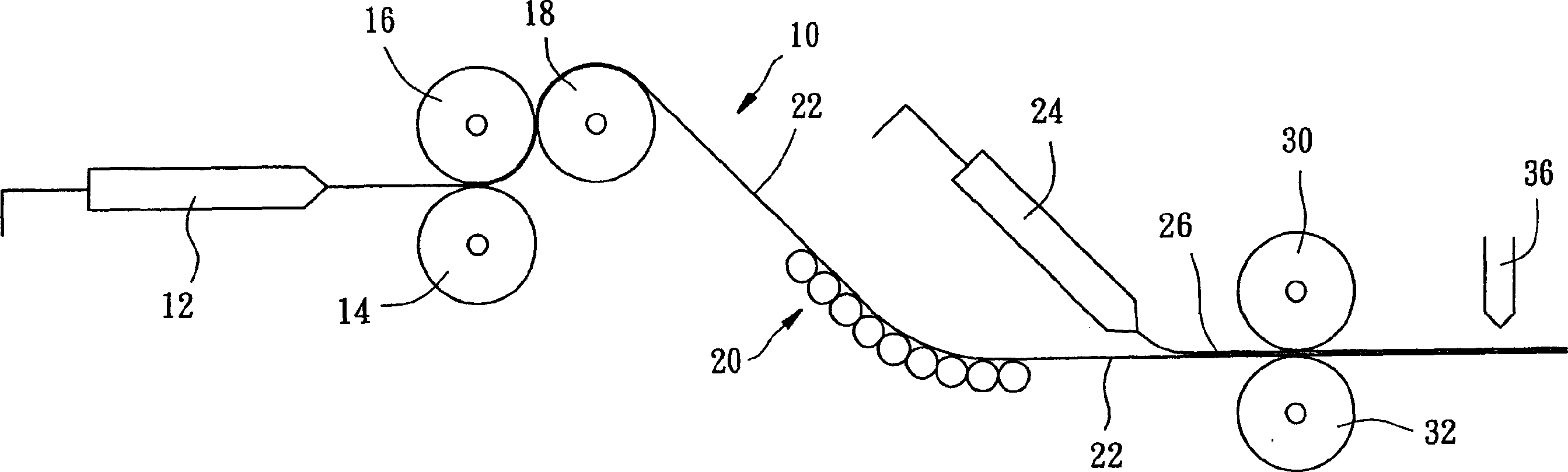

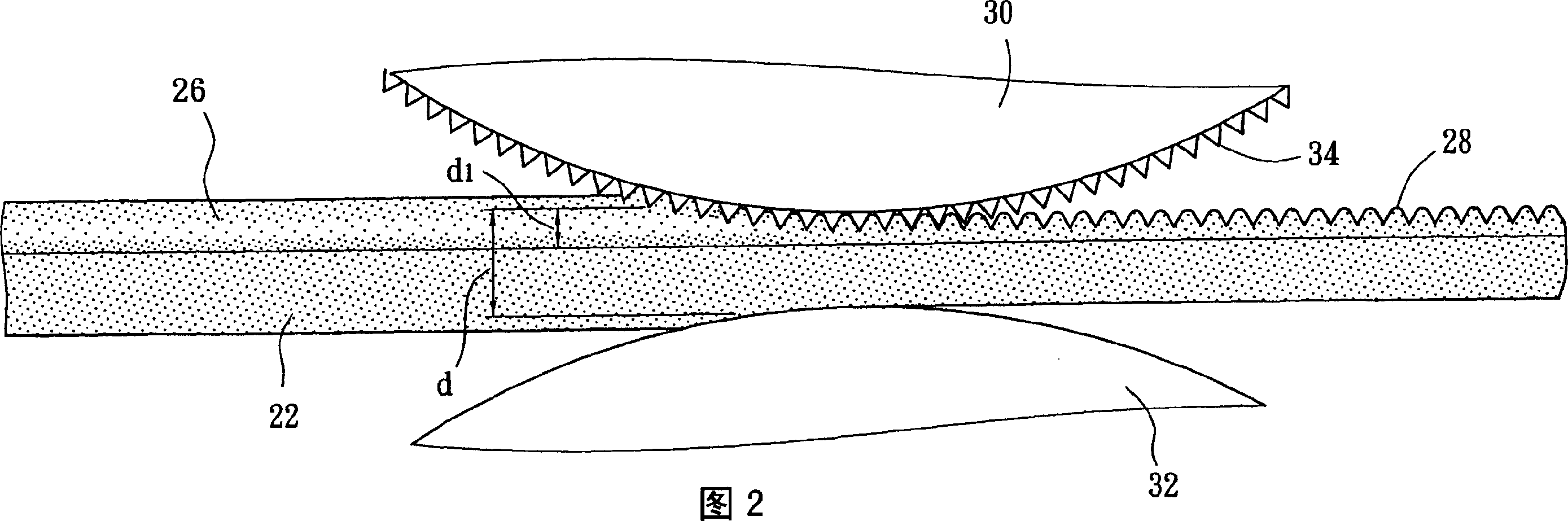

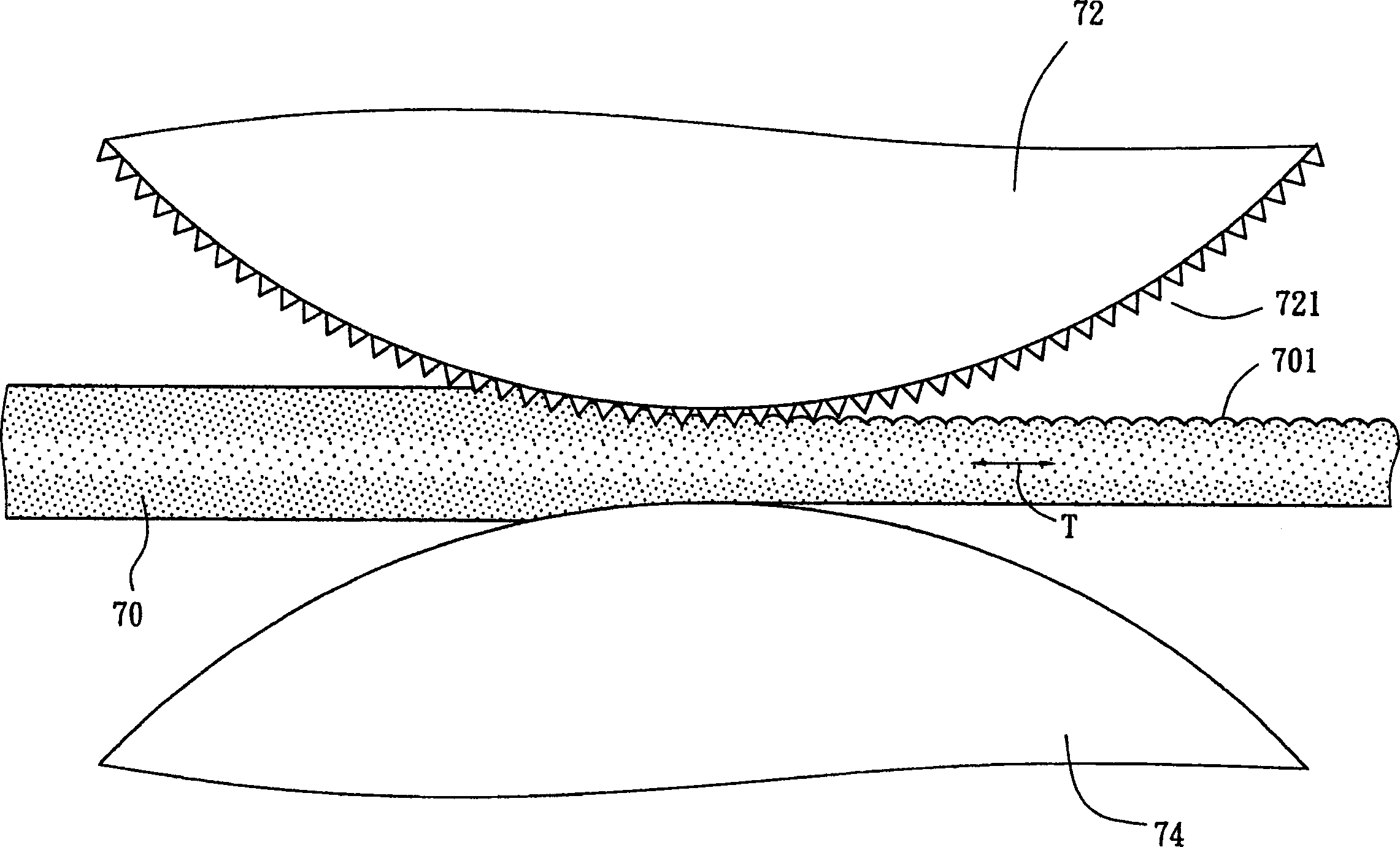

[0020] see figure 1 As shown, the device for manufacturing a plate with embossing on the surface provided by a preferred embodiment of the present invention includes: a base material supply device 10, a cooler 20, a skin layer supply device 24, a rolling press device and cutting device 36.

[0021] The substrate supply device 10 provides a solid elongated substrate 22 and includes a conventional extruder 12 and three rollers 14 , 16 , 18 . The extruder 12 can provide a plastic material in a molten state, such as polycarbonate (Polycarbonate, PC), polymethyl methacrylate (Polymethyl methacrylate, PMMA), cycloolefin polymer (Cyclic Olefins Polymer, COP) or It is a cyclic olefin copolymer (Cyclic Olefins Copolymer, COC). The rollers 14 , 16 , 18 are arranged at the outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com