Novel lead core steel pipe U-shaped damper

A damper, U-shaped technology, applied to bridge parts, bridges, buildings, etc., can solve the problems of small restoring force of shear plate damper, metal damper can not be applied, and large deformation capacity of damper is poor, so as to achieve good economy High efficiency, high rigidity and good plastic deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

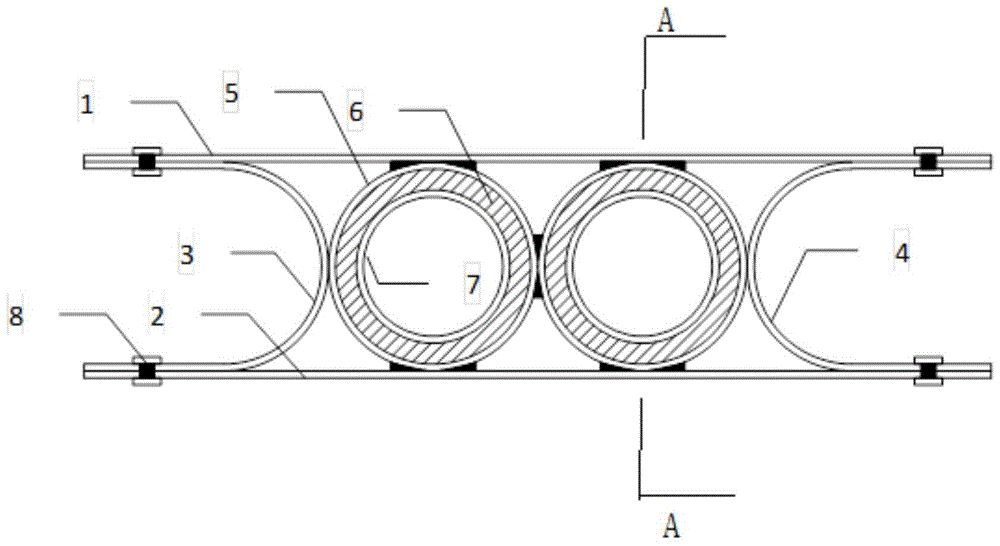

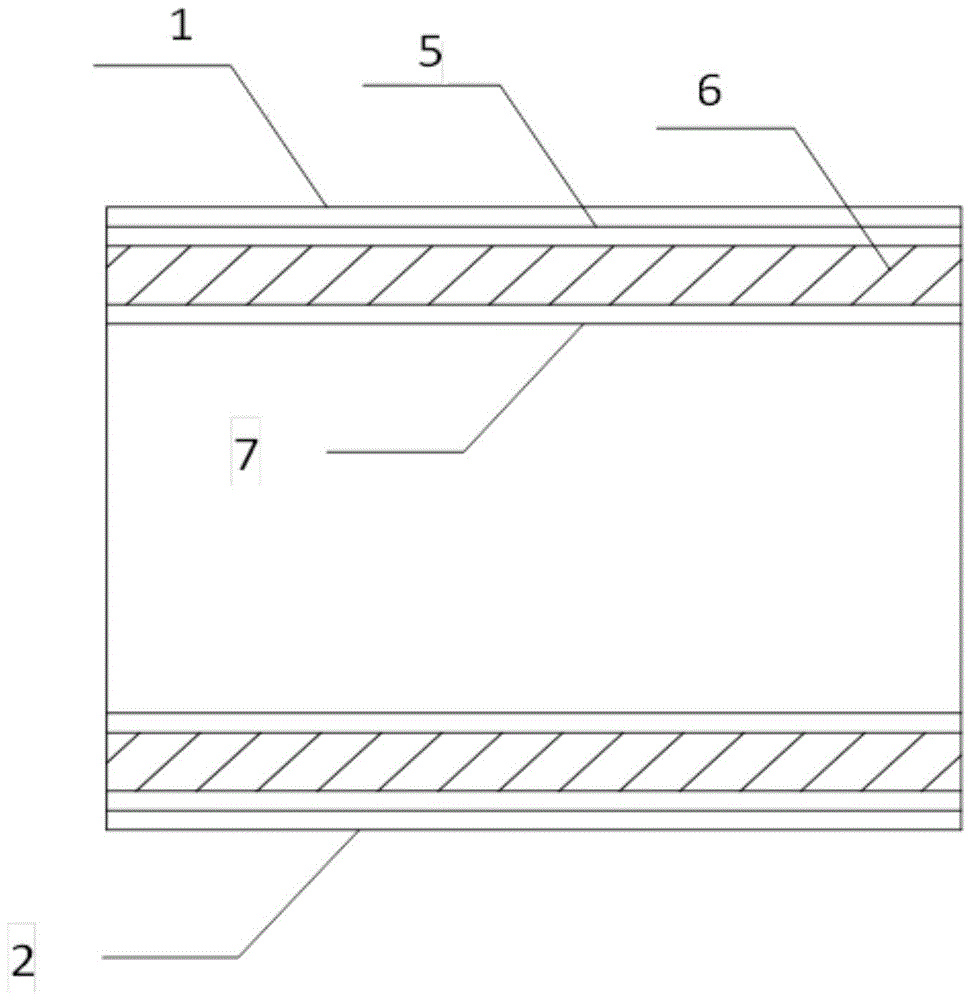

[0029] Such as figure 1 The lead core steel pipe U-shaped damper shown is composed of an upper cover plate, a lower cover plate, U-shaped metal plates on both sides and a lead core filled steel tube in the middle. The lead core filled steel tube is composed of an outer steel tube, a lead core filled layer and an inner Layer steel pipe composition.

[0030] To make lead-filled steel pipes, firstly, the axes of the outer steel pipe 5 and the inner steel pipe 7 are coincident, perpendicular to the horizontal plane and nested, and hot-melted lead is poured into the space between the two layers of steel pipes to form the lead-filled layer 6 .

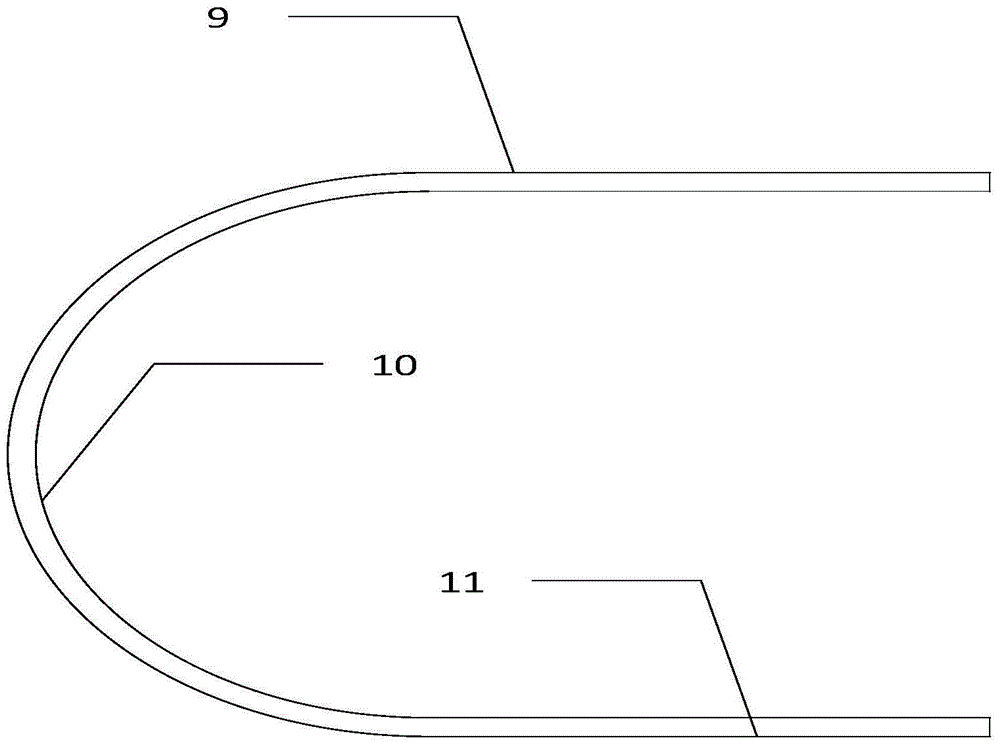

[0031] Make U-shaped metal plate, metal plate is processed into three sections, top straight section 9, middle arc section 10, bottom straight section 11; same diameter. Bolt holes are reserved in the straight section

[0032] To make the upper and lower cover plates 1 and 2, bolt holes need to be reserved.

[0033] Install and manufact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com