Super-plasticity diffusion connecting clamp and technology for metal bipolar plate

A metal bipolar plate, diffusion connection technology, applied in metal processing equipment, welding equipment, manufacturing tools, etc., can solve the problems of low precision, low energy conversion efficiency, virtual welding, etc., to achieve convenient disassembly and save processing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Combining with the accompanying drawings in the description, taking the superplastic diffusion connection of 5083 aluminum alloy bipolar plates as an example, the specific implementation process of the present invention is further described.

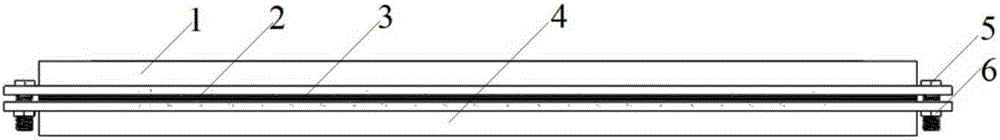

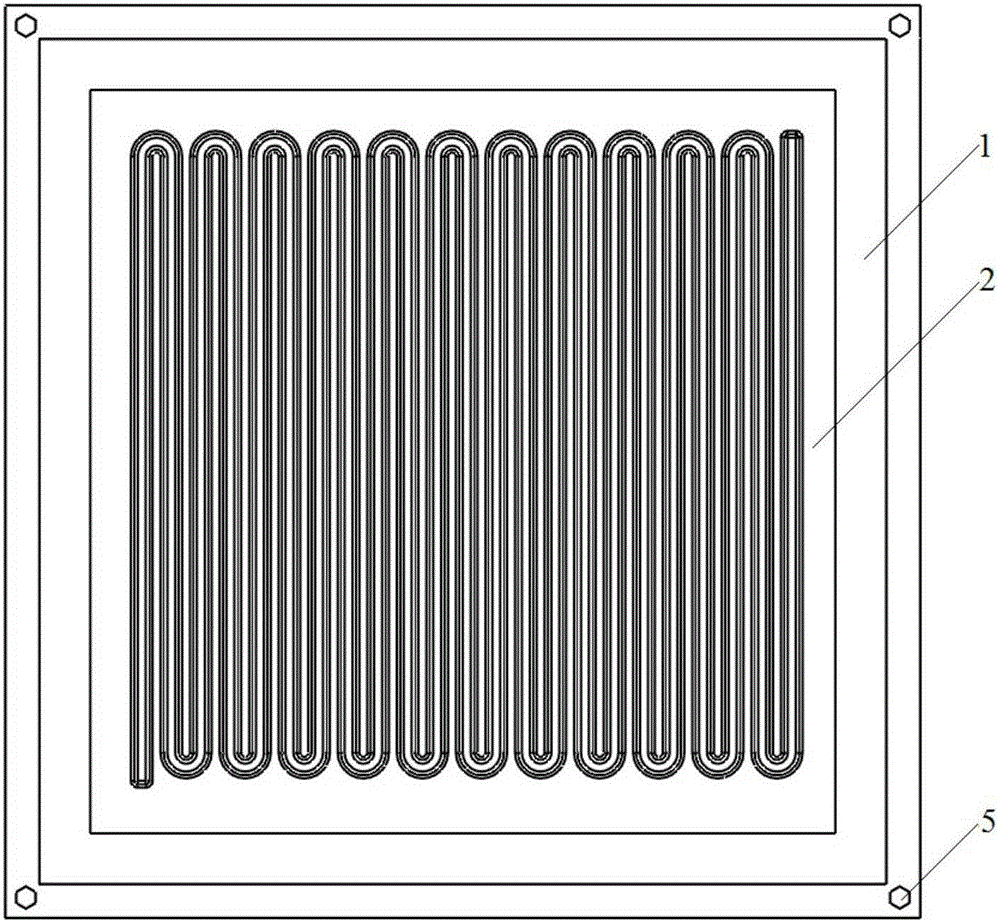

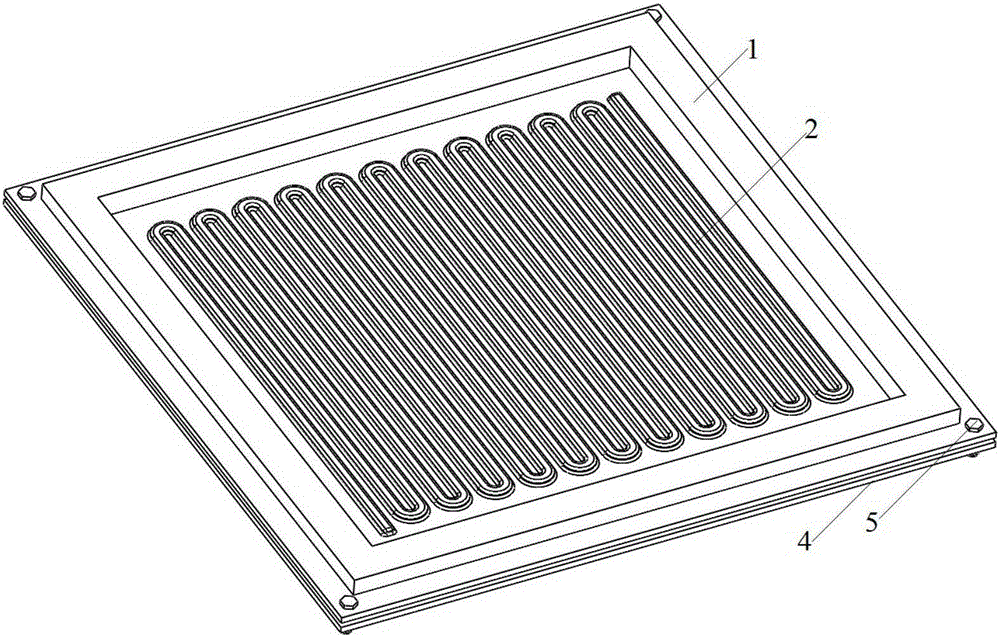

[0030] Such as Figure 1~5 As shown, a metal bipolar plate superplastic diffusion connection fixture is composed of an upper pressing plate 1 , a lower pressing plate 4 , bolts 5 and nuts 6 .

[0031] The metal bipolar plate is composed of the upper plate 2 and the lower plate 3 with the same structure. The upper plate 2 and the lower plate 3 are rectangular in structure and placed symmetrically up and down; the upper plate 1 and the lower plate 4 have the same structure, and the inner side is hollow. Rectangular frame, the outer side is a rectangular thin plate flange, the outer boundary of the rectangular frame of the pressure plate coincides with the outer boundary of the metal bipolar plate, the shape and size of the rectangul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com