Cathode for electrolytic machining of small-size inner wall annular groove and using method thereof

A small size, ring groove technology, applied in machining electrodes, electric machining equipment, electrode manufacturing, etc., can solve the problem that the cathode and the inner wall of the workpiece tube are not concentric and different axes, the positioning surface is difficult to maintain in the same horizontal plane, and there is no automatic centering. , positioning function and other issues, to achieve the effect of reducing stray corrosion, simple structure and convenient implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below with reference to the accompanying drawings, so as to facilitate the understanding of technical personnel.

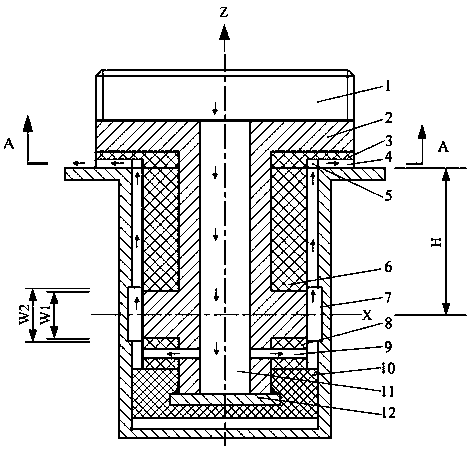

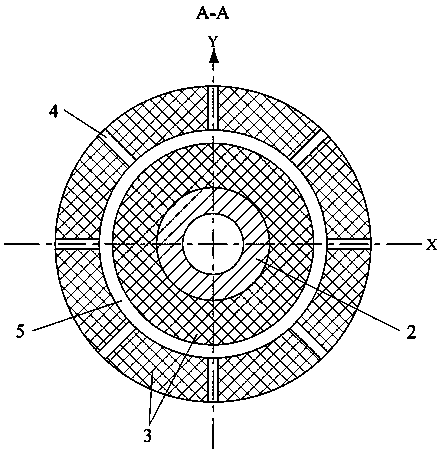

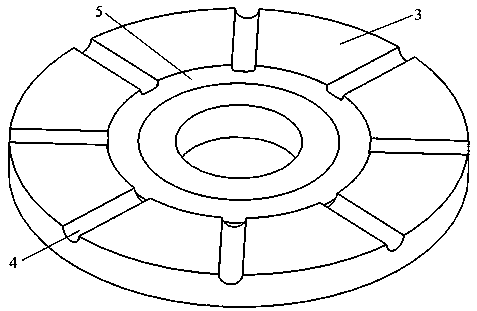

[0021] see Figure 1-Figure 3 , a small-sized inner wall ring groove electrolytic machining cathode, including a conductor 2 with an inverted "soil" cross section and a plug 12, the outer wall of the upper end of the conductor 2 is provided with an external thread 1, and the middle of the conductor 2 is provided There is an annular boss, and the inside of the conductor 2 is a through-hole structure along the axial direction.

[0022] The lower end of the electric body 2 is welded with a plug 12 whose diameter is larger than that of the conductor 2, and the lower end of the conductor 2 and the periphery of the plug 12 are provided with a cover-shaped bottom insulating layer 10, and the ring shape of the bottom insulating layer 10 A lower insulating ring 8 is arranged between the upper end and the conductor 2. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com