Blisk blade profile subtle electrochemical machining electrode and machining method

A technology of integral blisks and electrodes, which is applied in the direction of electrochemical processing equipment, metal processing equipment, manufacturing tools, etc., and can solve the problem of inability to achieve no margin machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

[0033] The premise of the embodiment of the present invention is that on the basis of using electrolysis or other methods to groove the overall blisk, the margin of the blade profile is basically controlled at 1-1.5mm. The embodiments of the present invention mainly focus on finishing the blade profiles of the integral blisk, as well as the difficult-to-machine front and rear edges and flow channels. The embodiment of the present invention is based on a multi-axis high-frequency narrow-pulse fine vibration electrolysis machine tool.

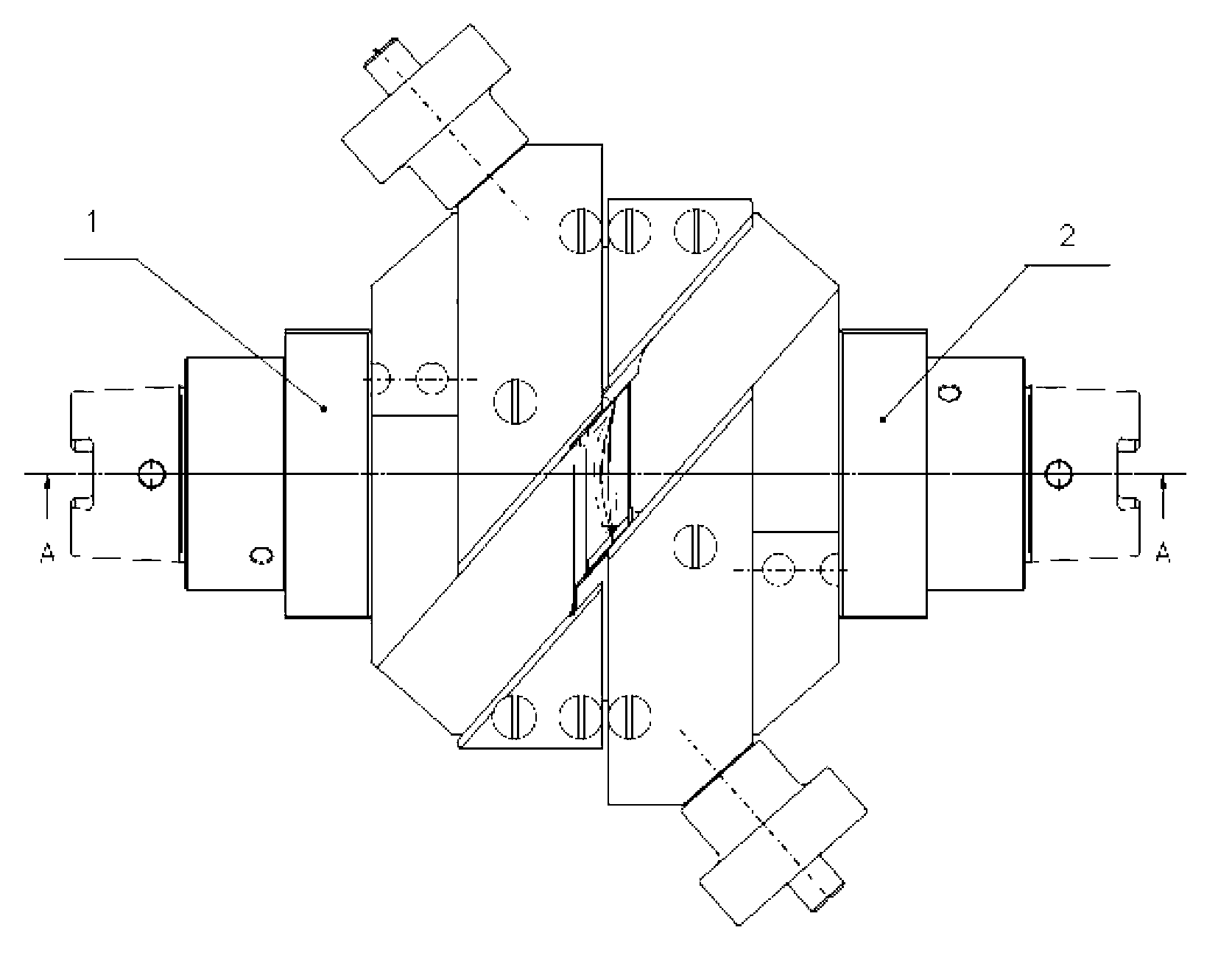

[0034] Such as figure 1 As shown, an electrode for fine electrolytic machining of an integral blisk leaf type, the device includes a left electrode device 1 and a right electrode device 2;

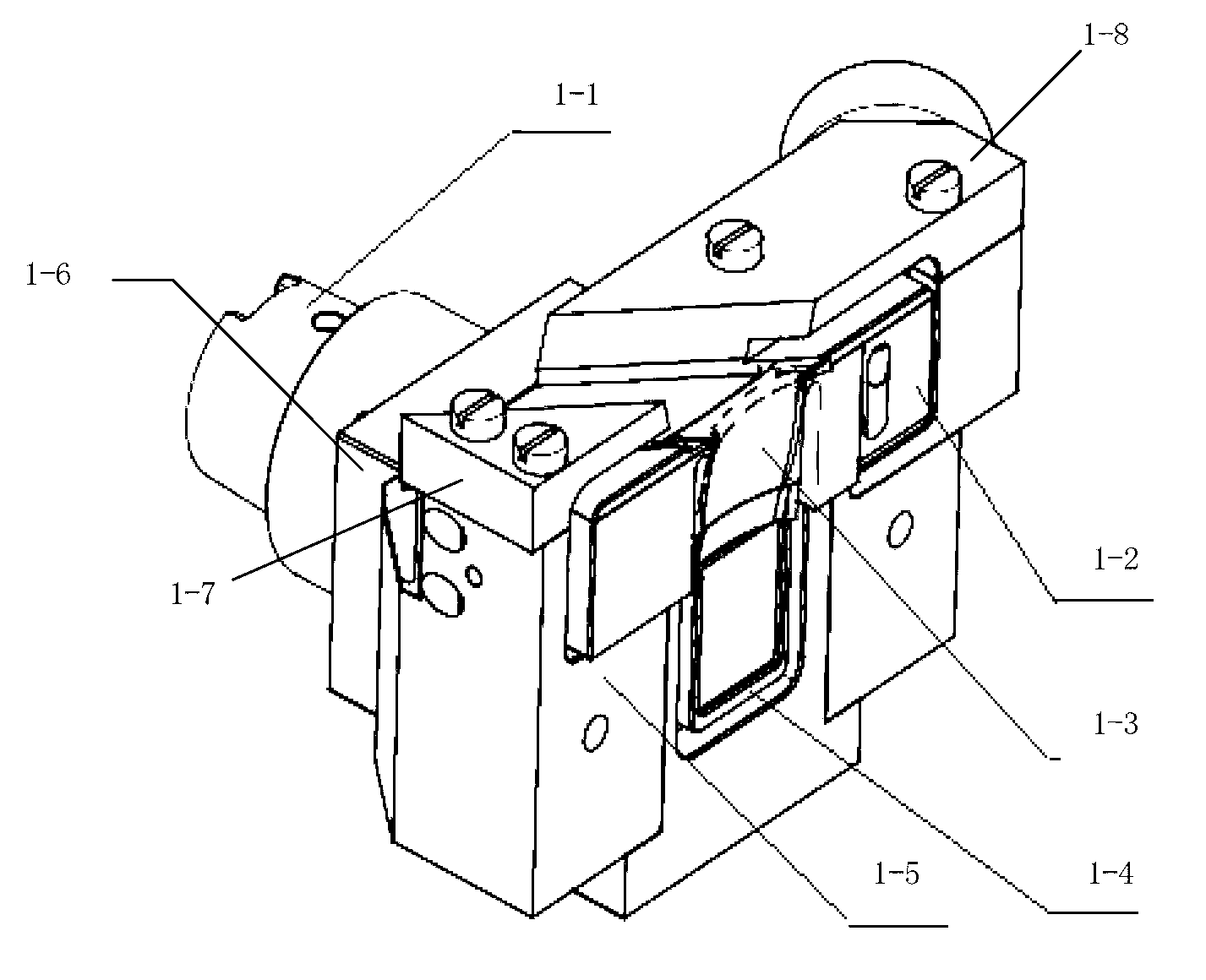

[0035] Such as figure 2 As shown, the left electrode device 1 includes an HSK high-precision hydraulic chuck 1-1, a first auxiliary liquid supply...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com