Combinational processing method for micro-array axle hole

A combined machining and microarray technology, which is applied in the field of combined machining of microarray shaft holes, can solve the problems of difficulty in guaranteeing machining accuracy, low processing efficiency, and difficult processing of microarray shaft hole processing technology, and achieve convenient processing and high processing efficiency , Improve the effect of quality and efficiency

Inactive Publication Date: 2007-12-12

HARBIN INST OF TECH

View PDF0 Cites 30 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] In order to solve the problems of the existing microarray shaft hole processing technology that the processing accuracy is difficult to guarantee, the processing efficiency is low, and the shape is complex and difficult to process, the present invention provides a microarray shaft hole combined processing method

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment approach 1

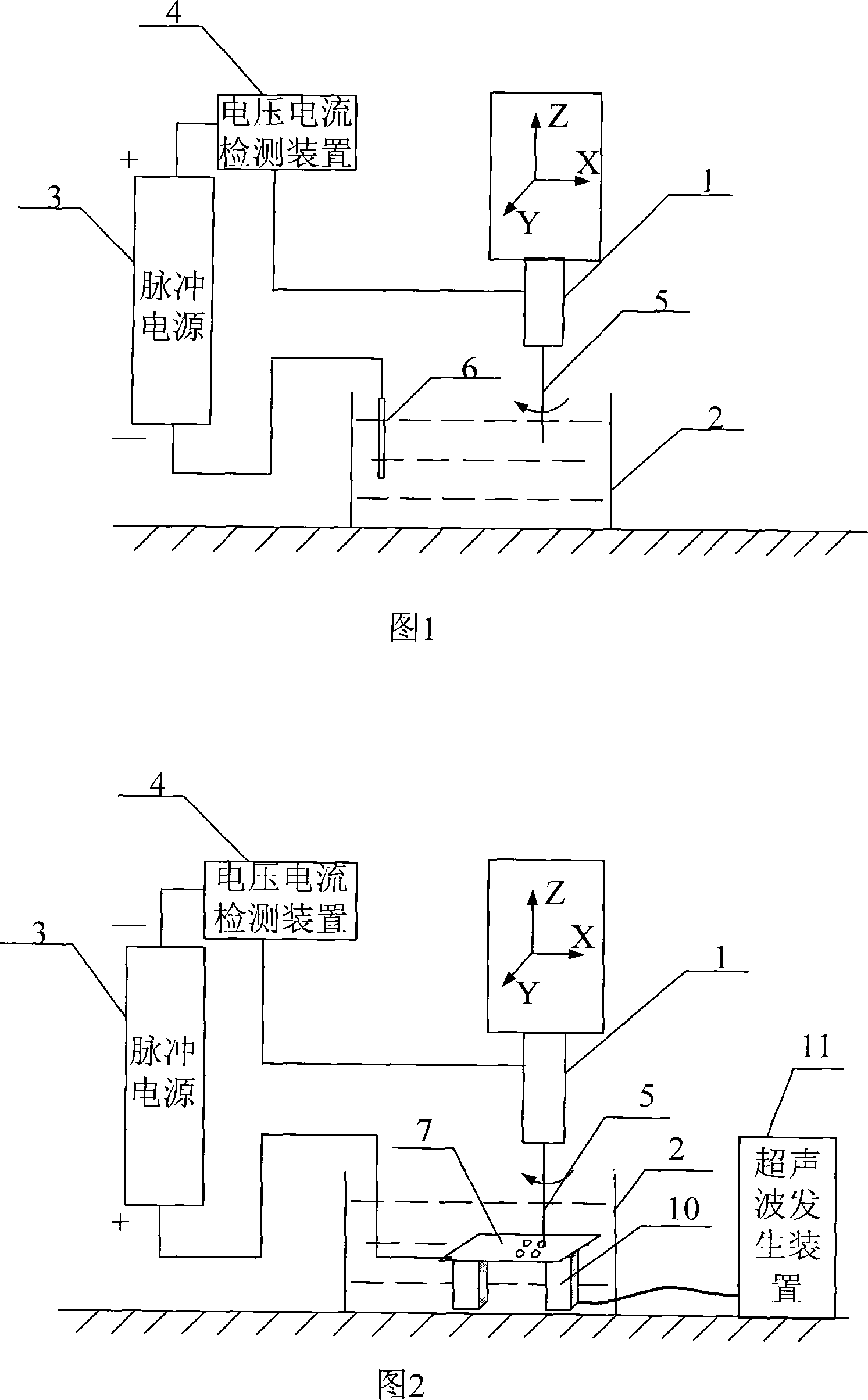

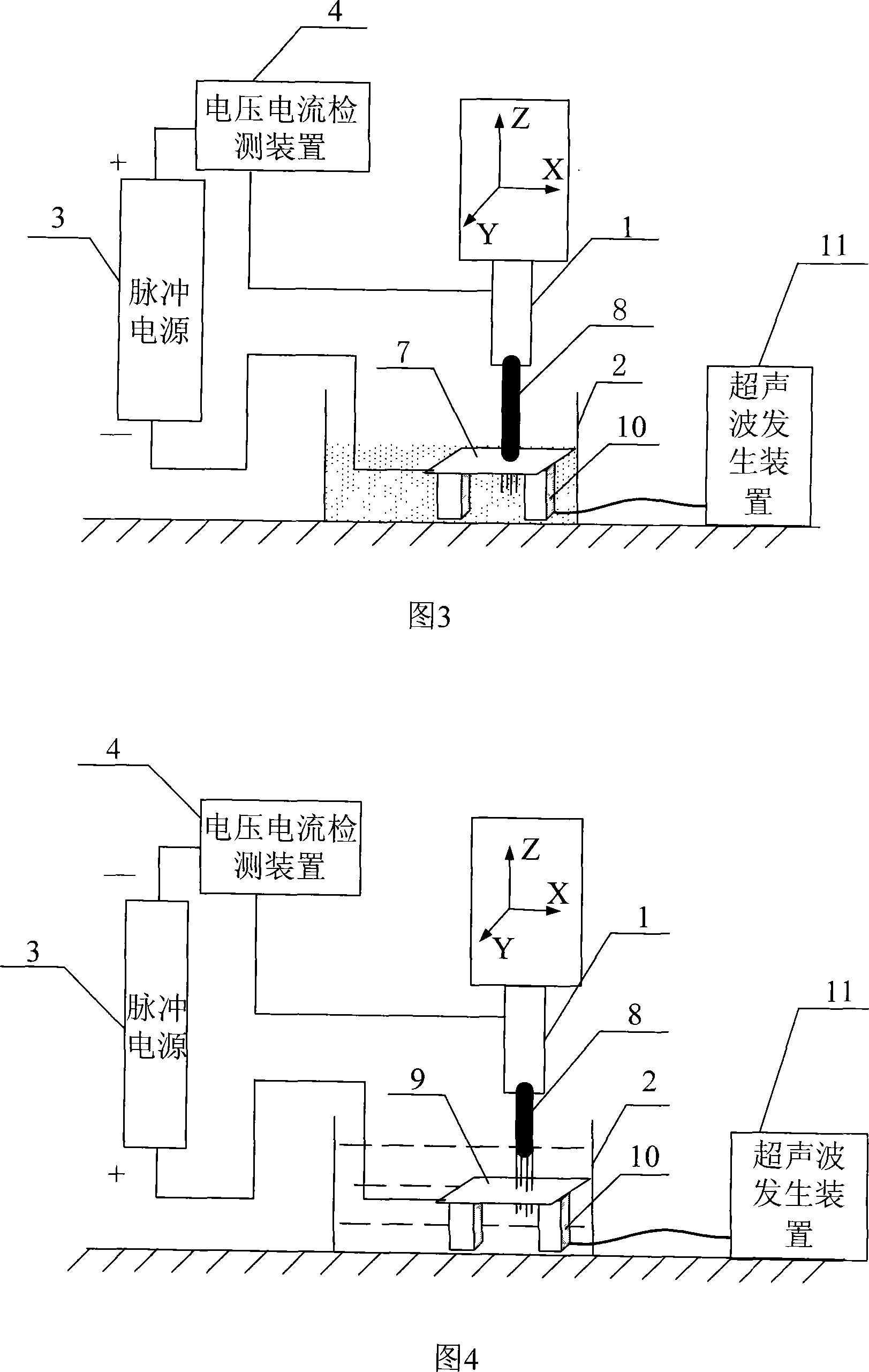

[0012] Specific embodiment one: below in conjunction with Fig. 1, Fig. 2, Fig. 3 and Fig. 4 specifically illustrate this embodiment, in this embodiment, complete by the following steps:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to the micro matrix shaft hole combination machining method with the combination of electrochemical machining, electrical spark machining, and hypersonic recombination, to solve the difficulties of un-assured precision, low machining efficiency, and complex shape hard to machining. It makes single micro electrode through electrochemical machining, machining micro matrix master hole on the flat electrodes, making micro matrix shaft through electrical spark machining and complex supersonic vibration, and using micro matrix shaft and electrochemical machining to make the micro matrix shaft hole. It has high machining precision, high in efficiency and convenient.

Description

technical field [0001] The invention relates to a combined processing method of fine array shaft holes of metal alloy materials cross-fused by technologies such as electrolytic processing, micro electric discharge processing and ultrasonic compounding. Background technique [0002] Microarray shaft holes of alloy materials are widely used in many fields. In the field of life sciences, microarray axes can record the activity of neurons in the cerebral cortex, decipher brain behavior instructions, and help treat brain injury diseases, which has played a huge role in promoting the development of life sciences and human health. More importantly, the micro-array axis can be processed by micro-electromachining to process micro-array holes, and micro-array holes also have a wide range of applications. Such as printer inkjet hole array, screen structure, spinneret and MEMS (micro-electromechanical system) micro-jet, micro-pump and other micro-structures. [0003] The use of precis...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23H5/02

Inventor 迟关心王振龙曾伟梁朱保国孙立忠

Owner HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com