Electrochemical machining process for array micro type hole

An electrochemical machining and micro-electrode technology, applied in electrochemical machining equipment, electric machining equipment, machining electrodes, etc., can solve the problem of poor shape accuracy and surface finish of laser machining, unsuitable for batch production of array micro-holes, EDM machining Low efficiency and other problems, to achieve the effect of good shape consistency, reduced stray corrosion effect, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

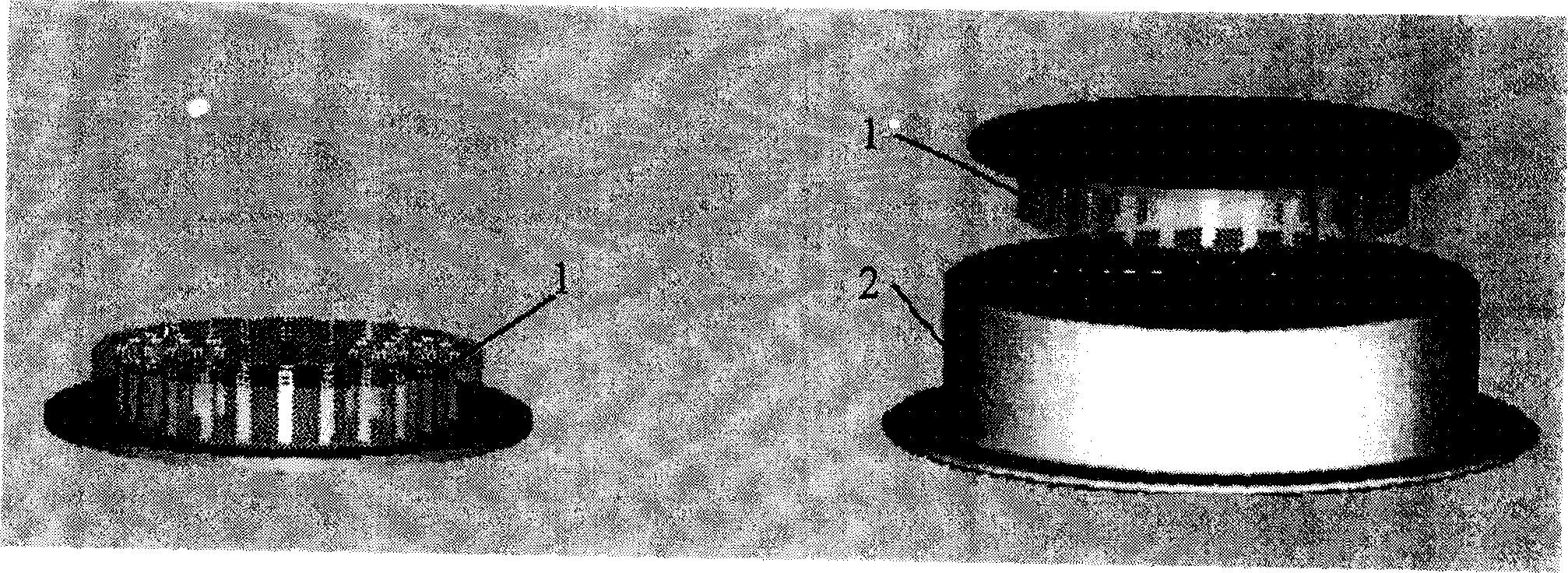

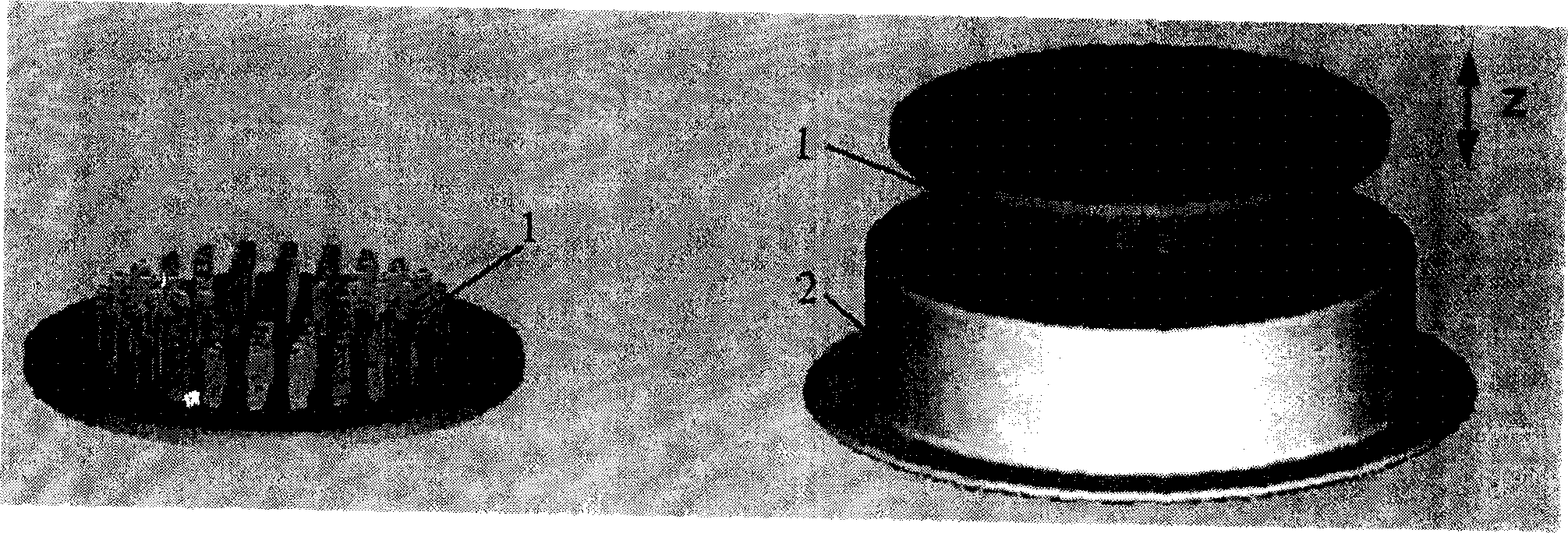

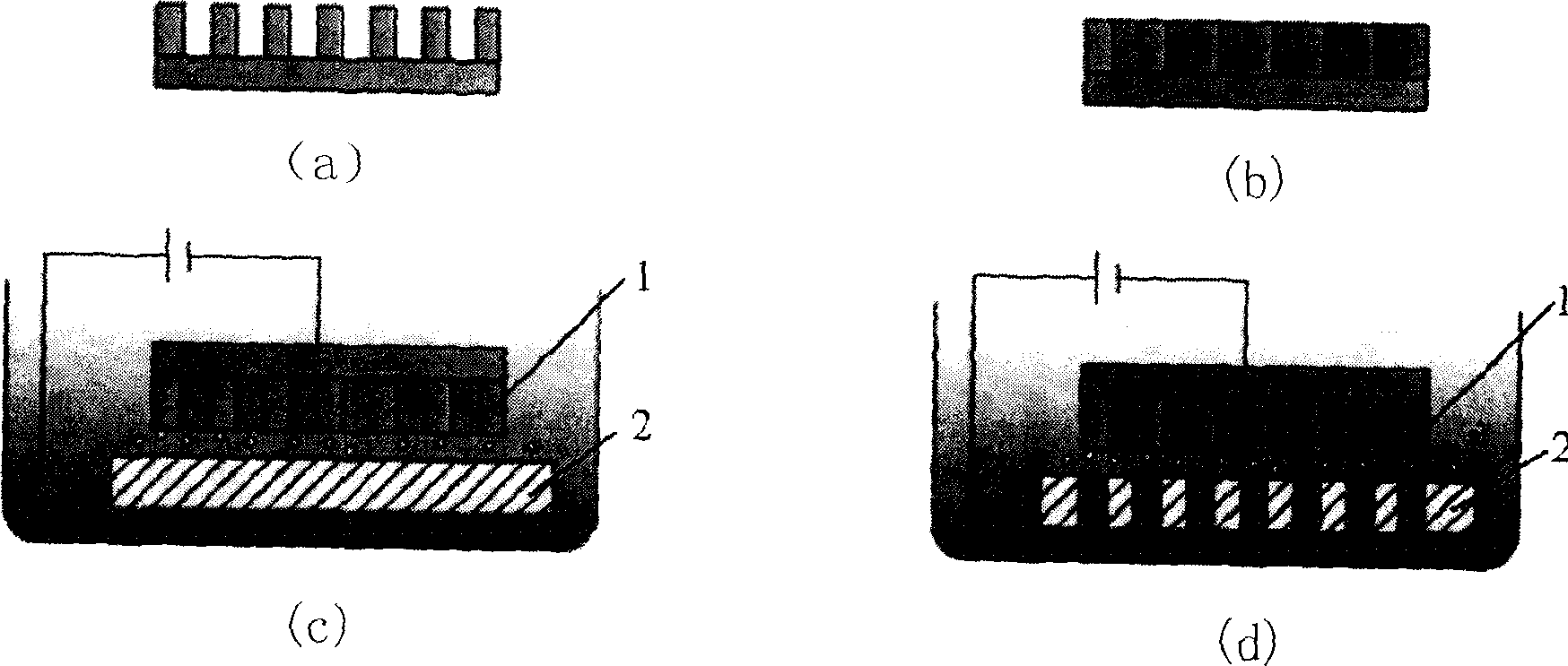

[0034] The present invention provides an electrochemical machining process for array micro-holes based on a micro-electrochemical process such as figure 1 or figure 2 shown. Firstly, the micro-array electrode 1 is designed and manufactured, and then the workpiece 2 is electrolytically processed by the micro-array electrode 1 to obtain the required micro-array hole.

[0035] The following examples are provided in conjunction with the summary of the present invention.

[0036] 1. Electrochemical processing of micro-holes with small aspect ratio arrays, such as figure 1 shown.

[0037] According to the shape and size of the required array micro-holes, the array micro-electrodes 1 are designed and manufactured; the gaps of the electrodes are filled with insulating gel, and the end faces are ground flat. Then, the workpiece 2 is electrolytically etched using the electrode array.

[0038] There are two methods for preparing the array micro-electrodes used in the electrochemica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com