Circulating wire cutting electrode system and processing method for electrolytic wire cutting

A technology of cutting processing and electrode system, which is applied in the direction of processing electrodes, electric processing equipment, electrochemical processing equipment, etc., can solve the problems that the electrochemical reaction ions cannot be replenished in time, the processing cannot be continued, and the processing gap is small, so as to achieve no processing Effect of heat-affected zone, no residual stress, and reduced processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

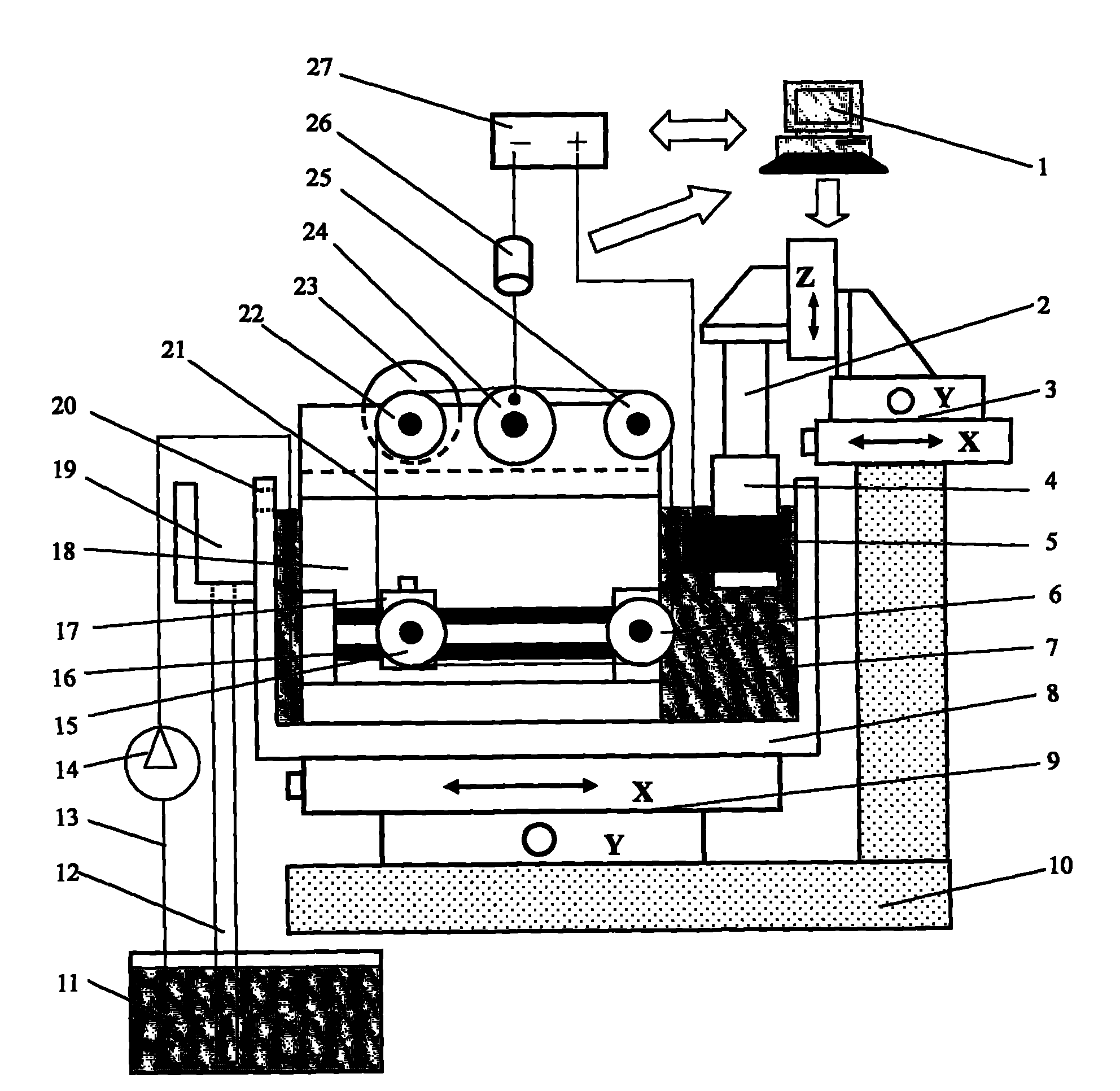

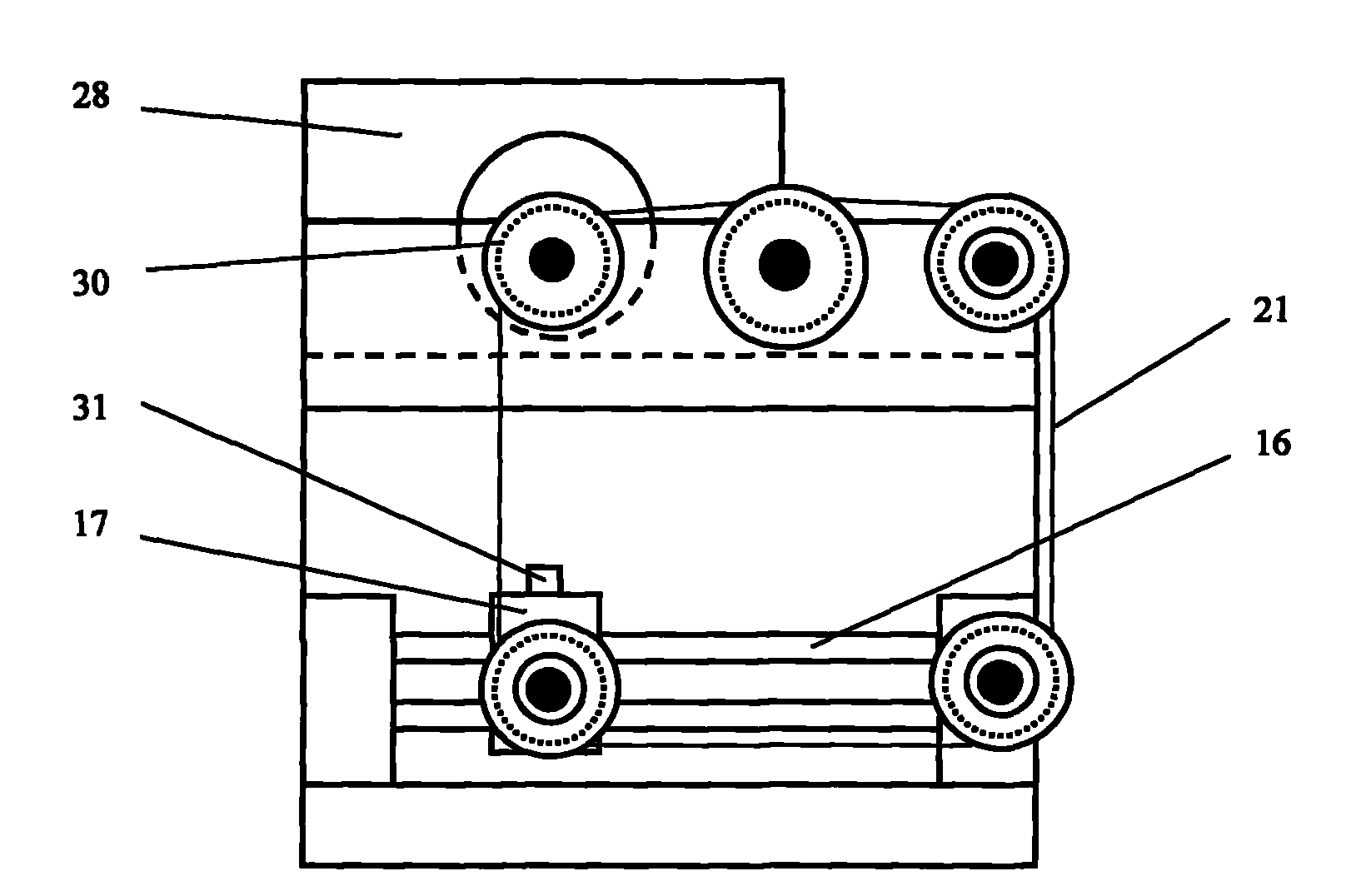

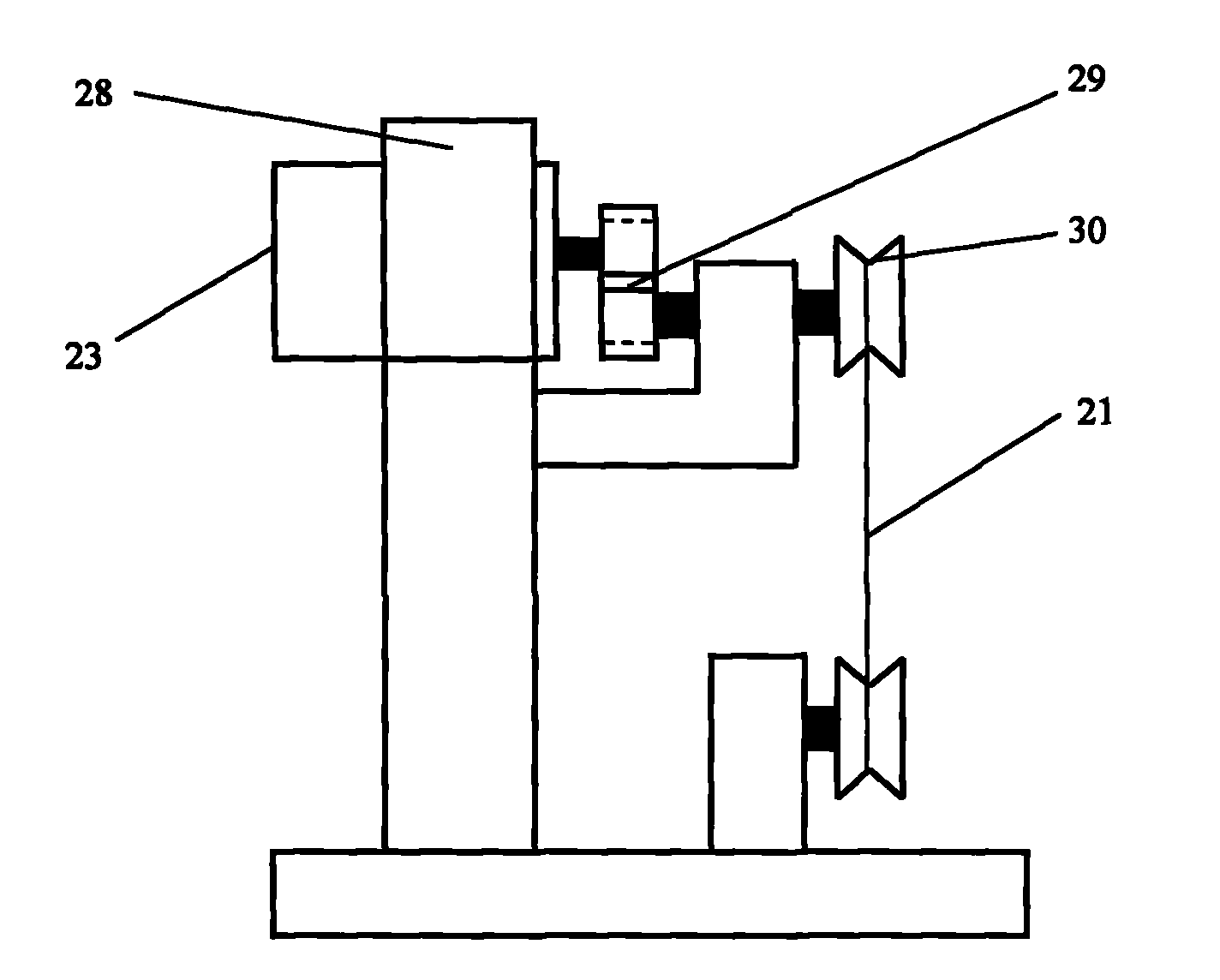

[0018] Combine below figure 1 , figure 2 , image 3 and Figure 4 Illustrate method of the present invention, implementation process passes through following several steps successively:

[0019] 1. Reference Figure 4 , the metal wires are butted end to end by a cold joint machine to form a ring, and then the connection is polished with large-mesh sandpaper, and the polished ring-shaped metal wire is used as the cathode of the tool. The principle of cold splicing machine: cold splicing machine is a kind of machine that does not need any additives and electric energy. It makes the metal wire pass through a special mold, and under certain extrusion, the pure metal lattices are mixed and combined with each other to realize molecular fusion. The connection principle of atomic structure, so as to weld the cold welding equipment of various alloy wires

[0020] 2. Reference figure 2 , image 3 and Figure 4 , make wire-feeding frame 18 with insulating materials such as plex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com