Device and method for manufacturing large-length-diameter-ratio nanoscale shafts

A technology for preparing devices with a large aspect ratio, which is applied in the direction of manufacturing tools, metal processing equipment, electrochemical processing equipment, etc., and can solve the problems of limited repeatability, inability to prepare nanoscale shafts with large aspect ratio, and high price of platinum wire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

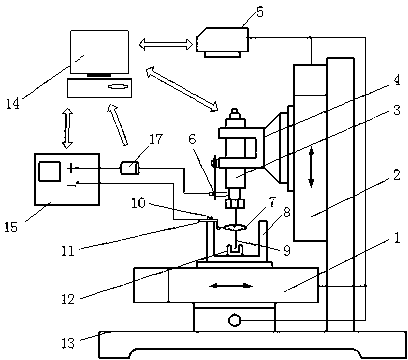

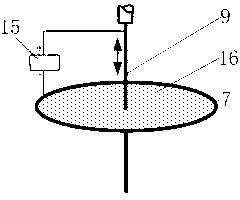

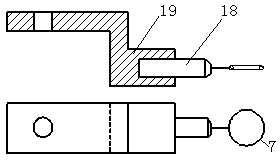

[0019] according to figure 1 As shown, the nano-scale slender axis liquid film method electrochemical etching processing device of the present invention, such as figure 1 As shown, the device includes an active vibration isolation platform 13, an X-Y axis moving platform 1, a Z axis precision displacement platform 2, a computer 14, a PCI motion control card 5, a rotating main shaft 3, an electric device 6, a positioning part 8, and a DC power supply 15 , cathode horizontal ring 7. It is characterized in that the process described above, the anode tungsten wire clamped on the rotating spindle 3 obtains the required linear reciprocating motion in the Z-axis direction through the Z-axis linear precision moving platform 2 . The cathode horizontal circular ring 7 is fixed in the positioning member 8 through the cathode clamp 11 and the cathode clamp fixing screw 10, so as to ensure that the circular surface is in the horizontal direction. It should be noted that before the ring i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com