Anti-adhering knife/blade with surface micromoulding

A technology of surface micro-modeling and cutting tools, which is used in the manufacture of tools, metal processing machinery parts, maintenance and safety accessories, etc. It can solve the problems of coating material falling off, loss of anti-wear and protection functions, etc., to improve the friction state, inhibit the The effect of sticking to the knife and improving the lubricating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] specific implementation plan

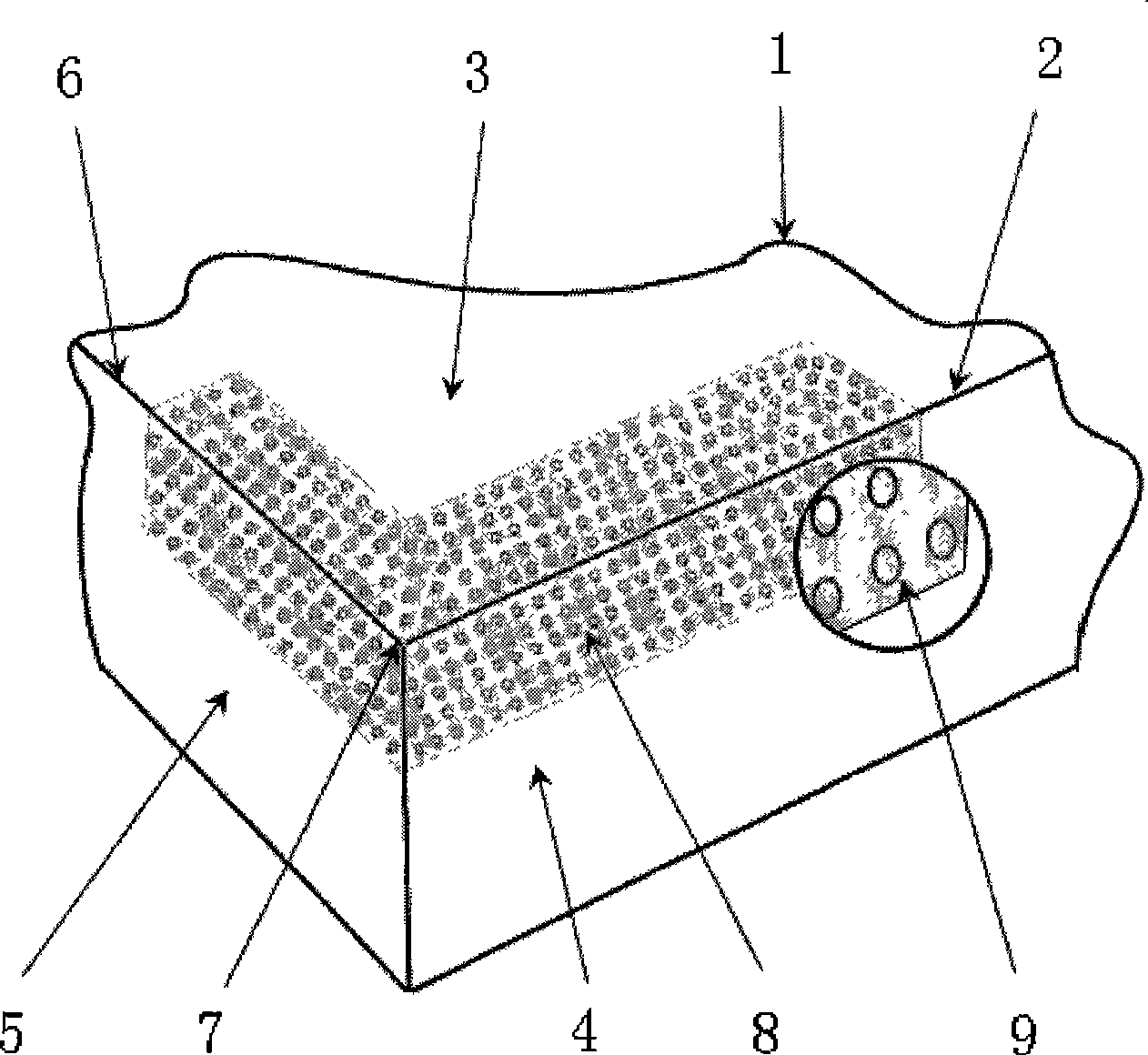

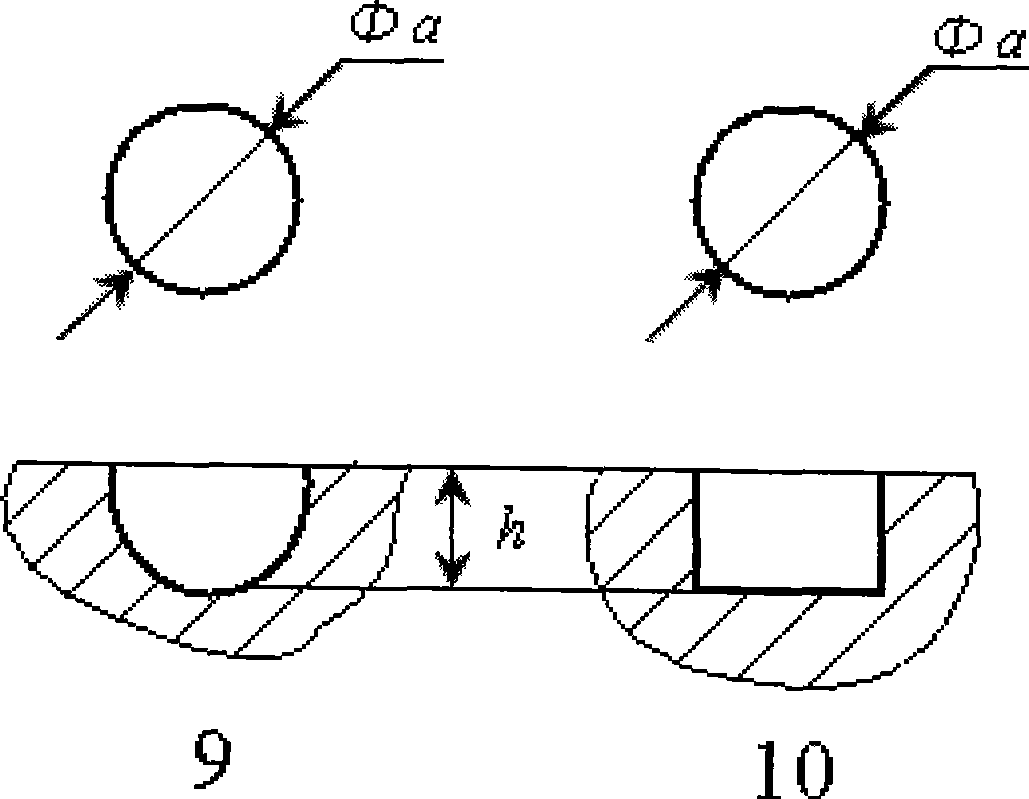

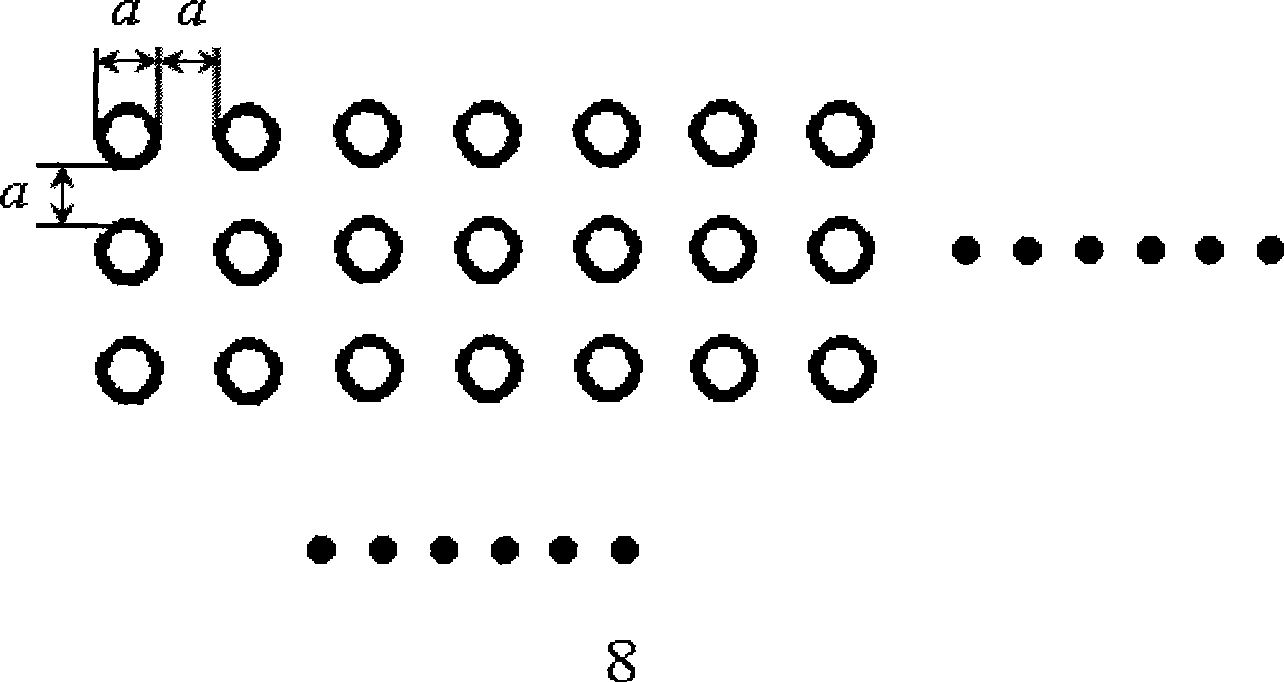

[0013] Such as figure 1 and figure 2 Shown is the anti-bonding and wear-resistant cutting tool with surface micro-modeling of the present invention. In areas where wear is prone to occur, such as the front and flank surfaces near the cutting edge, micro-manufacturing techniques such as electrochemical machining or laser machining are used to process some micro-pit array structures. Such as the micropit structure, the diameter of a single micropit is about 10-80 μm, and the depth is 5-30 μm. The distance between adjacent micropits depends on the distribution, and is generally the size of a micropit diameter. The base material consists of a hard metal material (tungsten carbide, high-speed steel), or a ceramic material.

[0014] In addition, the design of the geometric parameters of the tool surface micro-modeling has an impact on the size of the anti-bonding ability. The geometric parameters of the micromodels include the geometry and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com