Overall process linear flow flexible protection sleeve material electrochemical machining device and method

A technology of flexible flow and processing equipment, which is applied in the direction of electric processing equipment, electrochemical processing equipment, processing electrodes, etc., can solve the problem of not being able to reduce stray corrosion in the processing area more effectively, unfavorable processing stability and processing accuracy, and processed areas. Solve problems such as stray corrosion, achieve good cavitation, improve stability and processing accuracy, and reduce the effect of stray corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

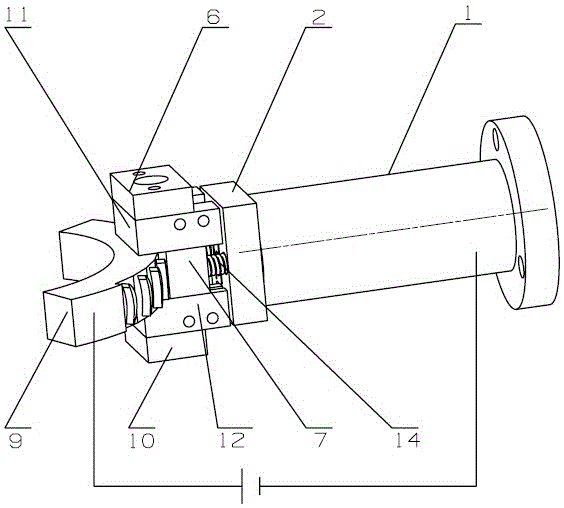

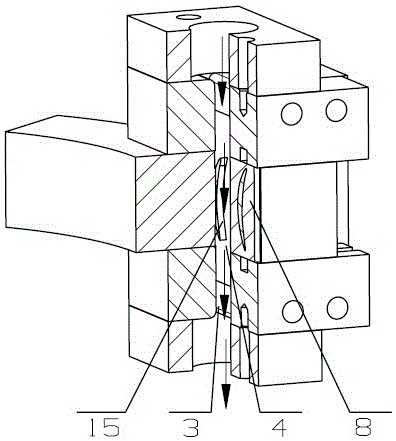

[0018] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

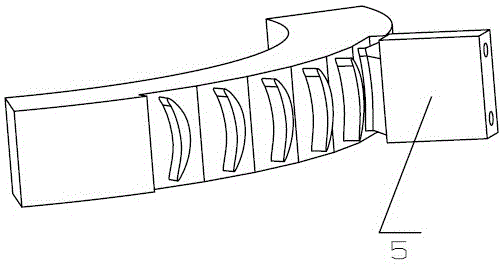

[0019] Implementation of the present invention-"the whole process in-line flow flexible protective cover material electrochemical processing method and device", the device includes a cathode head, a flexible insulating block, a cathode body, a cathode tailstock, a cathode rod, a liquid inlet block, and a liquid outlet block , Upper pressure block, lower pressure block, front slide block, rear slide block, workpiece, stop block, spring.

[0020] Cathode head, cathode body, cathode tailstock and cathode rod are all made of conductive metal material; flexible insulating block is made of flexible non-conductive material; liquid inlet block, liquid outlet block, upper press block, lower press block, front slider , The rear sliding block and the stop are made of non-conductive materials. The shape of the processed surface of the cathode head is desi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com