Energy storage device with both capacitor and lithium ion battery characteristics and manufacturing method thereof

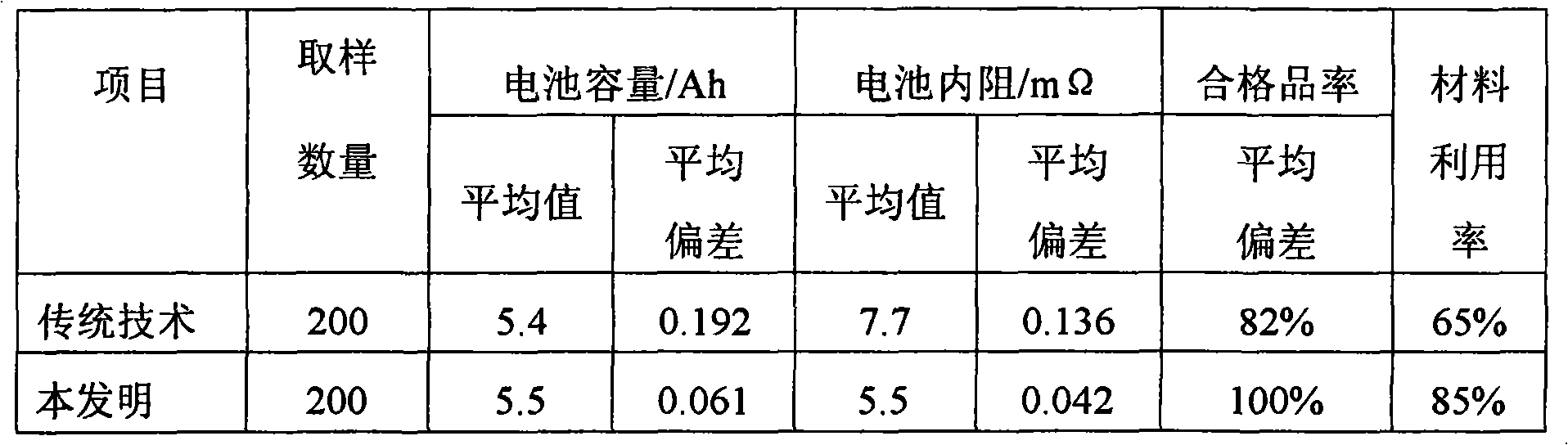

A technology of lithium-ion batteries and manufacturing methods, applied in the field of electrochemistry, can solve the problems of low energy density and unsatisfactory charging and discharging capabilities of supercapacitors, achieve excellent charging and discharging capabilities, cycle stability, good consistency, and improve utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The positive active material is 50% LiFePO 4 It is mixed with 50% activated carbon, binders, conductive agents, additives, solvents, etc. to prepare a slurry, which is coated, dried, rolled and cut to make a positive electrode sheet for supercapacitor batteries;

[0039] The negative active material is 50% artificial graphite and 50% activated carbon, mixed with binder, conductive agent, additive, solvent, etc. to prepare a slurry, which is coated, dried, rolled and cut to make a super capacitor battery negative electrode piece;

[0040] The assembly of the positive electrode sheet, the negative electrode sheet and the separator is assembled into a small winding core by winding, and 16 winding cores are used to install them into a stainless steel shell with a width, thickness and height of 70mm, 34mm and 65mm respectively. The cores are parallel to the wide side. It is arranged on the side of 34*65, and the change of the ratio of the weight of the positive electrode sh...

Embodiment 2

[0044] The positive active material is 95% LiFePO 4 It is mixed with 5% activated carbon, binders, conductive agents, additives, solvents, etc. to prepare a slurry, which is coated, dried, rolled and cut to make a positive electrode sheet for supercapacitor batteries;

[0045] The negative active material is 95% mesophase carbon microspheres and 5% activated carbon, mixed with binders, conductive agents, additives, solvents, etc. to prepare a slurry, which is coated, dried, rolled and cut to make super Capacitor battery negative plate;

[0046] The positive electrode sheet, the negative electrode sheet and the separator are assembled into a small winding core by winding, and 20 winding cores are used to put them into a stainless steel shell with a width, thickness and height of 70mm, 34mm and 65mm respectively. The cores are parallel to the wide side. It is arranged on the side of 34*65, and the change of the mass ratio of the weight of the positive electrode sheet to the neg...

Embodiment 3

[0050] The positive active material is 20% LiFePO 4 It is mixed with 80% activated carbon, binders, conductive agents, additives, solvents, etc. to prepare a slurry, which is coated, dried, rolled and cut to make a positive electrode sheet for supercapacitor batteries;

[0051] The negative active material is 20% modified natural graphite and 80% activated carbon, mixed with binder, conductive agent, additive, solvent, etc. to prepare a slurry, which is coated, dried, rolled and cut to make a super capacitor battery negative plate;

[0052] The assembly of the positive electrode sheet, the negative electrode sheet and the separator is assembled into a small winding core by winding, and 16 winding cores are used to install them into a stainless steel shell with a width, thickness and height of 70mm, 34mm and 65mm respectively. The cores are parallel to the wide side. It is arranged on the side of 34*65, and the change of the mass ratio of the weight of the positive electrode s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Energy density | aaaaa | aaaaa |

| Maximum power density | aaaaa | aaaaa |

| Energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com