Preparation and application of polyimide-imidazole micro-capsule hybrid membrane

A polyimide, imidazole microcapsule technology, applied in the direction of separation through membrane, membrane technology, semi-permeable membrane, etc., can solve the problem of gas separation that has not been reported in the literature, achieve excellent water retention performance, improve permeation flux, increase The effect of a large free volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

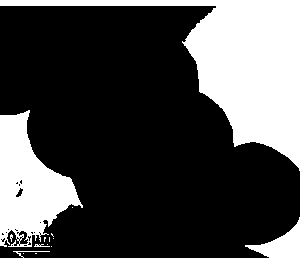

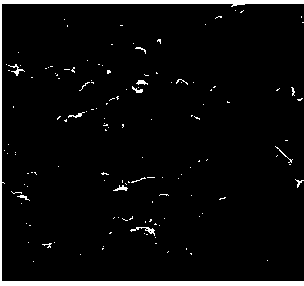

[0021] Preparation of Modified Silica Particles:

[0022] At a temperature of 30°C, disperse 3g of monodispersed silicon dioxide particles with a diameter of about 200nm into a solution containing 200ml of ethanol, 20ml of water, and 6ml of ammonia water, and then add 1ml of 3-(trimethyl Oxysilyl)propyl-2-methyl-2-acrylate (MPS) and stirred for 4 h, then centrifuged, washed with ethanol and water, and dried to obtain modified silica particles;

[0023] Preparation of imidazole microcapsules:

[0024] Take 0.3 g of the modified silicon dioxide particles and disperse them in 80 ml of acetonitrile for dispersing, and ultrasonically disperse for 2-4 hours to obtain a uniformly dispersed suspension. Then add 0.018g initiator 2,2'-azobisisobutyronitrile (AIBN) to the suspension and ultrasonically disperse for 5-10 minutes, then add 0.45ml reactive monomer vinylimidazole (VI) and 0.45ml cross-linking agent ethylene glycol dimethacrylate (EGDMA) and ultrasonic dispersion for 5-10 m...

Embodiment 2

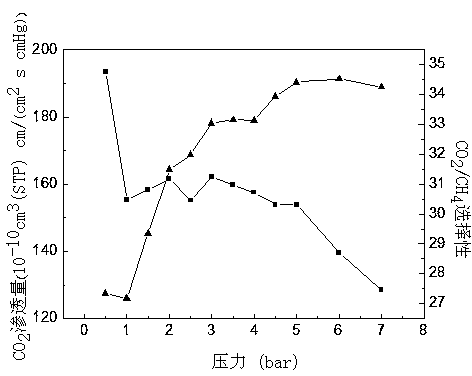

[0028] The process and conditions of this embodiment are the same as in Example 1, except that the amount of imidazole microcapsules added to the polyimide solution with a mass concentration of 6% is changed from 0.012g to 0.03g, and the prepared polyimide The carbon dioxide permeation flux of the imine-imidazole microcapsule hybrid membrane is 163.3×10 -10 cm 3 (STP) cm / (cm 2 s cmHg), CO 2 / CH 4 The selectivity is 31.3.

Embodiment 3

[0030] The process and conditions of this embodiment are the same as in Example 1, except that the amount of imidazole microcapsules added to the polyimide solution with a mass concentration of 6% is changed from 0.012g to 0.06g, and the prepared polyimide The carbon dioxide permeation flux of the imine-imidazole microcapsule hybrid membrane is 220.5×10 -10 cm 3 (STP) cm / (cm 2 s cmHg), CO 2 / CH 4 The selectivity is 30.2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com