Membrane device for treating oilfield produced water for reinjection and treating method

A produced water and membrane device technology, applied in the field of membrane devices for re-injection, can solve the problems of increased water production in oilfields, difficulty in meeting this requirement, emulsification of produced water, etc., and achieve long cleaning cycle, high degree of automation, and high throughput big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

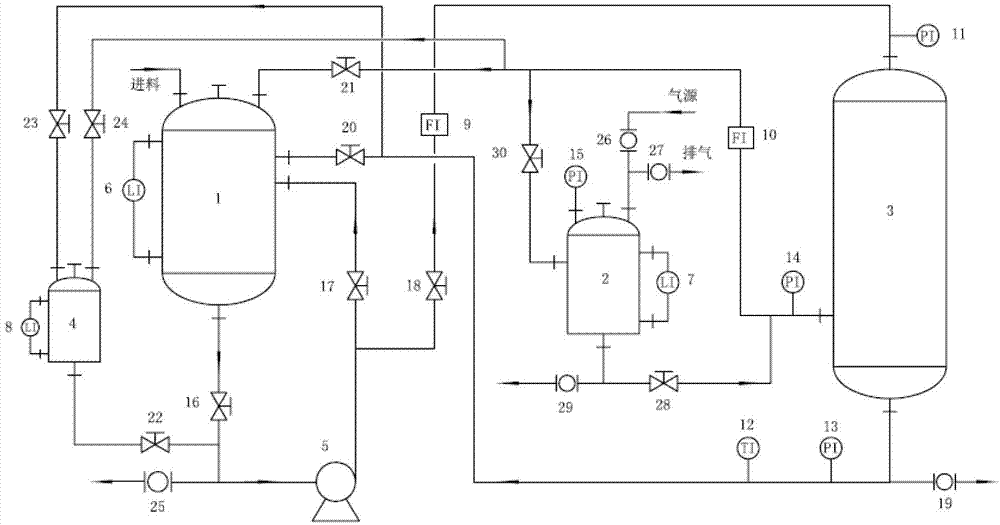

[0030] Example 1: Oilfield Produced Water Wastewater Treatment and Reinjection

[0031] After the oilfield produced water is treated by the settling tank, the total suspended matter content is 20mg / L, the total oil content is 18mg / L, and the median particle size is 7μm. It enters the membrane separation system. After separation, the clear liquid is injected into the formation through the water injection well and reinjected into the formation. The oily dope is returned to the settling tank.

[0032] The material enters the feed liquid tank 1, and the discharge valve 16 of the feed liquid tank is opened. The feed liquid enters the membrane separator 3 through the centrifugal pump 5 under the conditions of a pressure drop of 0.2MPa and a membrane surface flow rate of 3m / s, and the clear liquid passes through the clear liquid pipe. The valve 21 and the recoil tank feed valve 30 enter the feed liquid tank 1 and the recoil tank 2, and the concentrated liquid returns to the feed liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com