Technology for efficiently treating mine water by using ceramic membrane

A ceramic membrane, mine water technology, applied in neutralization water/sewage treatment, permeation/dialysis water/sewage treatment, etc., can solve the problems of high energy consumption, one-time investment, high operating cost, large investment, etc., to reduce pollution, Avoid unstable water quality and reduce investment and transportation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

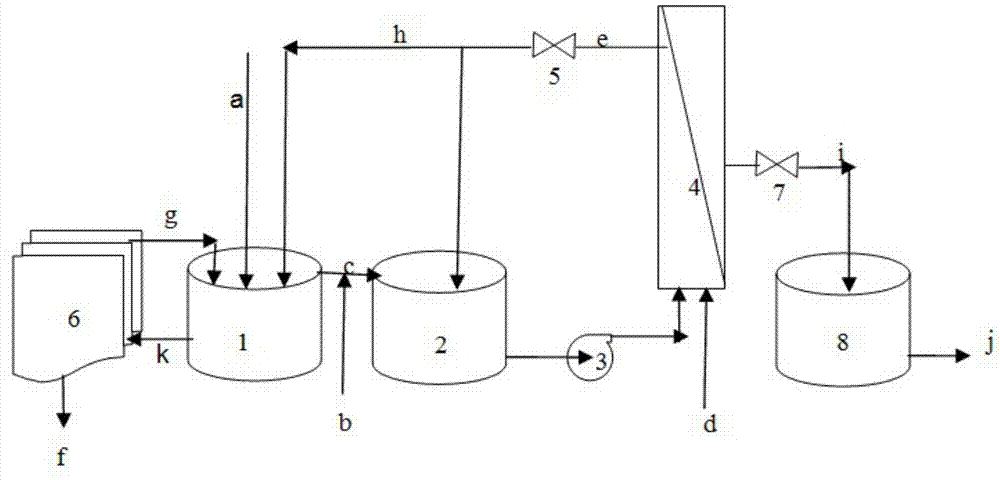

[0035] The mine water a of a certain coal mine in Shandong is treated by the process of the present invention, and enters such as figure 1 Shown in the mine water treatment process system. After the mine water a is homogeneously and uniformly adjusted, the supernatant c in the adjustment tank is mixed with acid b to adjust the pH=4.5 through the pipeline, and then enters the ceramic membrane ultrafiltration system, which passes through the ceramic membrane circulation tank 2 and the ceramic membrane circulation pump 3 in sequence. Enter the ceramic membrane module 4 for ultrafiltration. During the ultrafiltration process, gas d is introduced from the bottom of the ceramic membrane module 4 for enhanced filtration. The ratio of gas flow to liquid flow is controlled to be 0.55:1, and the gas pressure is 0.35MPa. After the ceramic membrane serum reaches the standard, it can be directly reused or further processed. After being concentrated to a certain concentration, the ceramic ...

Embodiment 2

[0039] The mine water of a certain coal mine in Shandong is treated by the process of the present invention, and enters such as figure 1 Shown in the mine water treatment process system. After the mine water is homogeneously and uniformly adjusted, the supernatant of the adjustment pool is mixed and added with acid through the pipeline to adjust the pH = 5, and then enters the ceramic membrane ultrafiltration. The ratio of flow to liquid flow is 0.64:1, and the gas pressure is 0.35MPa. After the ceramic membrane clear liquid reaches the standard, it can be directly reused or further treated. After the ceramic membrane concentrated liquid is concentrated to a certain concentration, it becomes a high-solid concentrated liquid and enters the regulating tank. The regulating tank also functions as a sedimentation tank. The sludge after sedimentation enters the plate frame Press filter. The plate and frame filter press sludge obtained after pressing can be discharged directly, and...

Embodiment 3

[0043] The mine water of a certain coal mine in Shandong is treated by the process of the present invention, and enters such as figure 1 Shown in the mine water treatment process system. After the mine water is homogenized and equalized, the supernatant of the adjustment tank is mixed with acid through the pipeline to adjust the pH=5.5, and then enters the ceramic membrane ultrafiltration. During the ultrafiltration process, gas is introduced from the bottom of the ceramic membrane module for enhanced filtration to control The ratio of flow rate to liquid flow rate is 1:1, and the gas pressure is 0.4MPa. After the ceramic membrane clear liquid reaches the standard, it can be directly reused or further treated. After the ceramic membrane thick liquid is concentrated to a certain concentration, it becomes a high-solid concentrated liquid and enters the regulating tank. The regulating tank also functions as a sedimentation tank. Plate and frame filter press.

[0044] In this em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com