Nickelic and chrome welding permeating flux-cored wire and preparing method

A flux-cored welding wire and high-nickel technology, which is applied in welding equipment, welding medium, welding/cutting medium/material, etc., can solve the problems of low nickel content in high-chromium cast iron flux-cored welding wire, achieve small spatter, less production, The effect of less smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

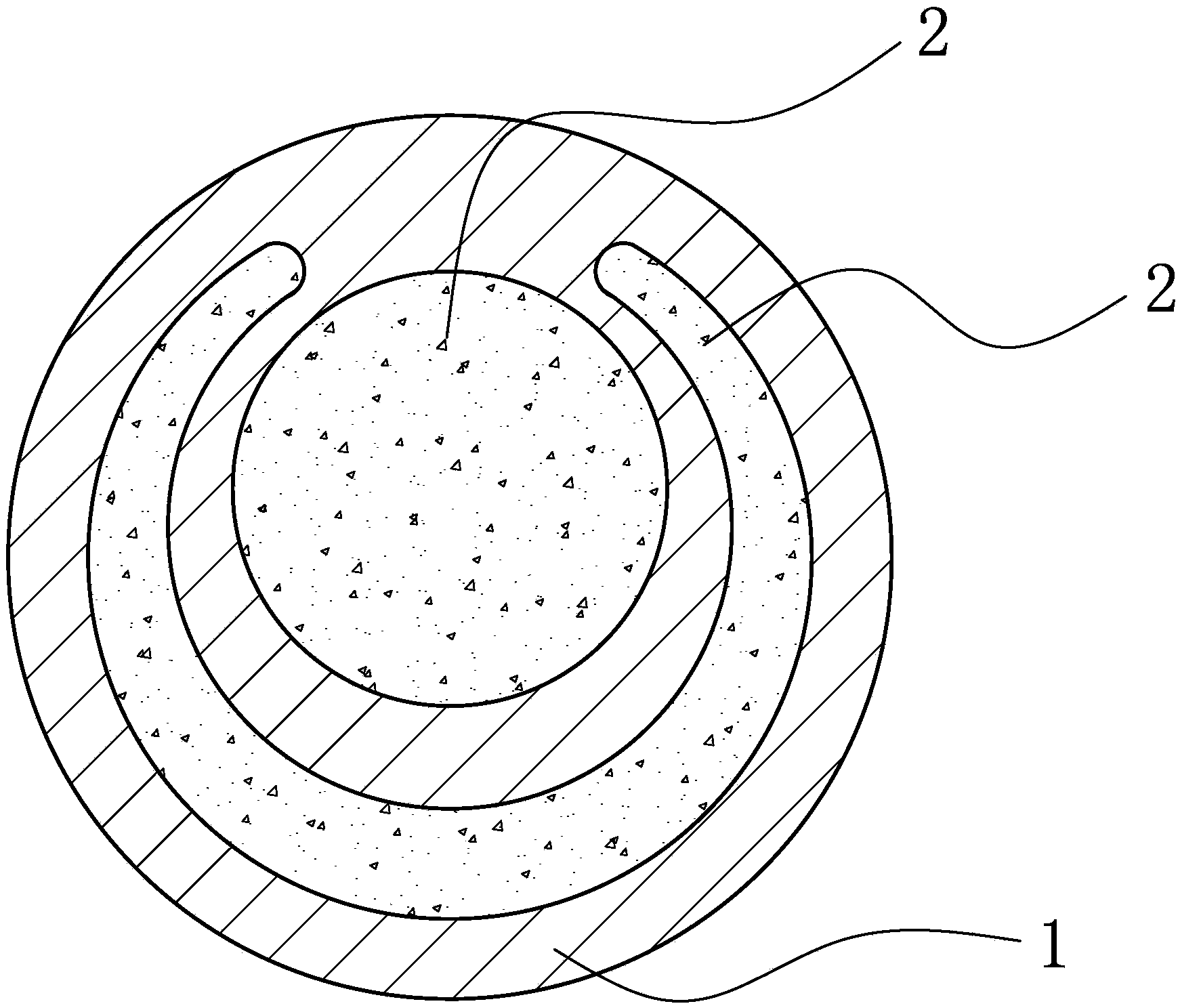

Image

Examples

Embodiment 1

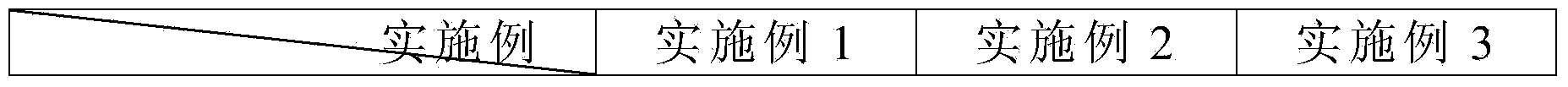

[0043] First, weigh the powder according to the powder and parts by weight of the drug core powder in Example 1 in Table 2, then bake the ore powder at 745°C, and bake the metal powder and alloy powder at 115°C, keep warm for 5 hours and then cool naturally . The treated powders were screened twice through a 100-mesh sieve, fully mixed, and prepared into drug core powder.

[0044] It is 0.40 ± 0.001mm to select nominal thickness according to the composition and mass percentage of embodiment 1 cold-rolled steel strip in table 1, and the cold-rolled steel strip that nominal width is 900mm is rolled into U-shaped groove structure for the first time, and to U-shaped groove Add the above-mentioned prepared core powder accounting for 8% of the total weight of the flux-cored wire, use a forming machine to close the U-shaped groove with the core powder and flatten it, and roll the cold-rolled steel strip into a U-shaped groove structure again, and again Add the above-prepared flux co...

Embodiment 2

[0046] First, weigh the powder according to the powder and parts by weight of the drug core powder in Example 2 in Table 2, then bake the ore powder at 750°C, and bake the metal powder and alloy powder at 120°C, keep warm for 6 hours and then cool naturally . The processed powders were screened twice through a 120-mesh sieve, fully mixed, and prepared into drug core powder.

[0047] Then, according to the composition and the mass percentage of embodiment 2 cold-rolled steel strip in table 1, it is 0.40 ± 0.001mm to choose nominal thickness, and the cold-rolled steel strip that nominal width is 950mm is rolled into U-shaped groove structure for the first time, and to U Add the above-mentioned prepared core powder accounting for 10% of the total weight of the flux-cored wire into the U-shaped groove, use a forming machine to close the U-shaped groove with the core powder and flatten it, and then roll the cold-rolled steel strip into a U-shaped groove structure. And add the abov...

Embodiment 3

[0049] First, weigh the powder according to the powder and parts by weight of the drug core powder in Example 3 in Table 2, then bake the ore powder at 755°C, and bake the metal powder and alloy powder at 125°C, keep warm for 7 hours and then cool naturally . And the treated raw material granules are screened once through a 140-mesh sieve, fully mixed, and prepared into drug core powder.

[0050] Then, according to the composition and mass percentage of embodiment 3 cold-rolled steel strip in table 1, it is 0.40 ± 0.001mm to choose nominal thickness, and the cold-rolled steel strip that nominal width is 1000mm is rolled into U-shaped groove structure for the first time, and to U-shaped Add the above-mentioned prepared core powder accounting for 10% of the total weight of the flux-cored wire into the U-shaped groove, use a forming machine to close the U-shaped groove with the core powder and flatten it, and then roll the cold-rolled steel strip into a U-shaped groove structure....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com