Co2 gas shielded stainless steel flux-cored welding wire and preparation method thereof

A technology of flux-cored welding wire and gas shielding, applied in welding equipment, welding medium, manufacturing tools, etc., can solve the problems of damage, large space occupation, small specific gravity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

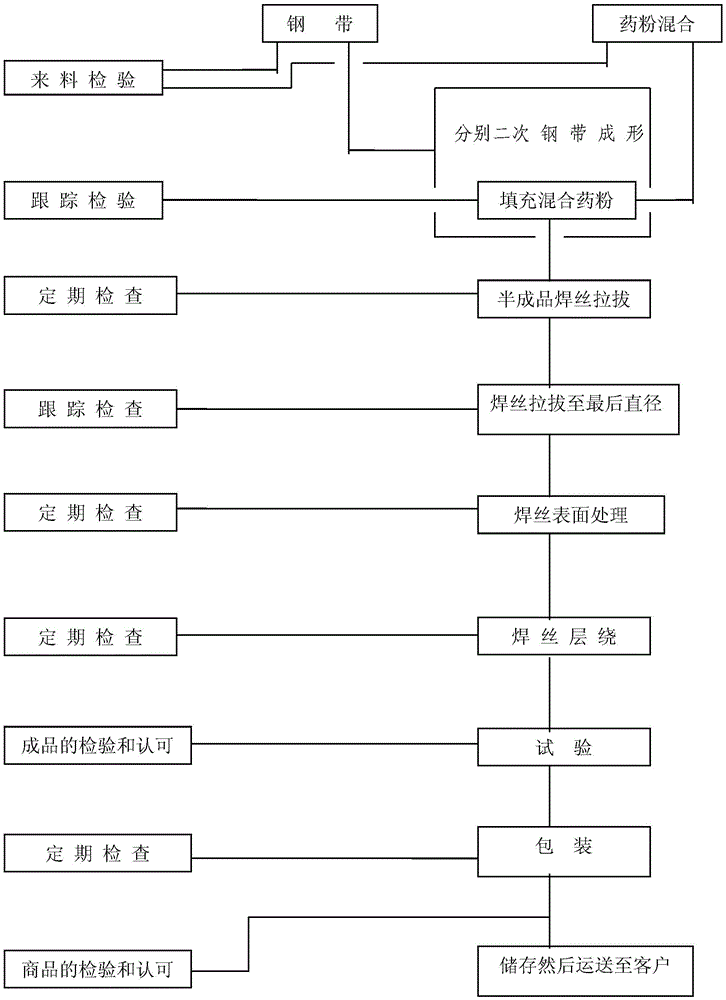

Method used

Image

Examples

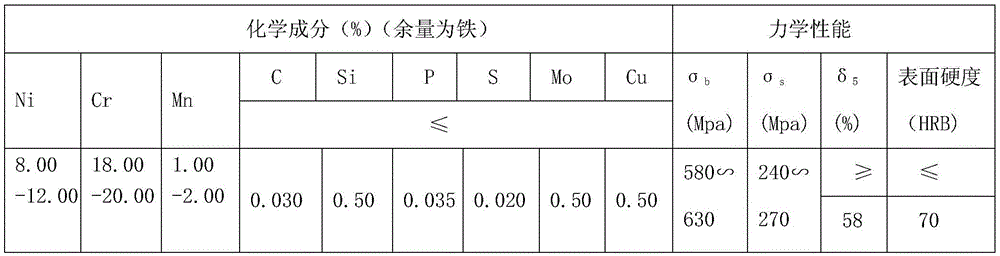

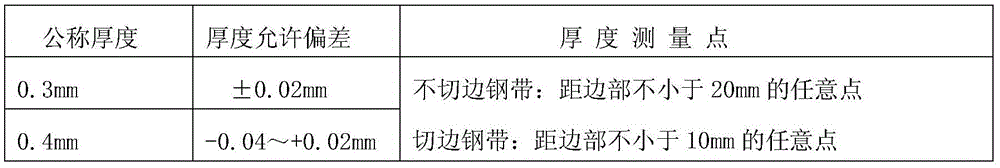

Embodiment 1

[0081] Select the steel strip with a nominal thickness of 0.40mm, cut the nominal width into a cold-rolled steel strip for flux-cored welding wire with a nominal width of 14mm, and use a forming machine to roll it into a U-shaped groove. Take 1000 grams of submerged arc welding flux-cored wire as an example: take 210 grams of rutile, 130 grams of silicon-manganese alloy, 170 grams of iron powder, 90 grams of nickel powder, 60 grams of aluminum-magnesium alloy, 180 grams of micro-carbon ferrochromium, and 100 grams of ferromolybdenum , 60 grams of ferrovanadium. Put all the raw materials into the mixer and mix for 30 minutes, then take 500 grams and add them to the U-shaped channel steel belt; close the U-shaped groove so that the drug core powder is wrapped in it and flattened, and rolled into a U-shaped groove again, and the remaining 500 The core powder is added to the U-shaped channel steel belt, and then drawn and reduced one by one by a wire drawing machine, so that the d...

Embodiment 2

[0097] Select the steel strip with a nominal thickness of 0.40mm, cut the nominal width into a cold-rolled steel strip for flux-cored welding wire with a nominal width of 14mm, and use a forming machine to roll it into a U-shaped groove. Take 1000 grams of submerged arc welding flux-cored wire as an example: take 180 grams of rutile, 150 grams of silicon-manganese alloy, 150 grams of iron powder, 120 grams of nickel powder, 50 grams of aluminum-magnesium alloy, 200 grams of micro-carbon ferrochromium, and 90 grams of ferromolybdenum , 60 grams of ferrovanadium. Put all the raw materials into the mixer and mix for 30 minutes, then take 500 grams and add them to the U-shaped channel steel belt; close the U-shaped groove so that the drug core powder is wrapped in it and flattened, and rolled into a U-shaped groove again, and the remaining 500 The core powder is added to the U-shaped channel steel belt, and then drawn and reduced one by one by a wire drawing machine, so that the d...

Embodiment 3

[0099] Select the steel strip with a nominal thickness of 0.40mm, cut the nominal width into a cold-rolled steel strip for flux-cored welding wire with a nominal width of 14mm, and use a forming machine to roll it into a U-shaped groove. Take 1000 grams of submerged arc welding flux-cored wire as an example: take 230 grams of rutile, 110 grams of silicon-manganese alloy, 150 grams of iron powder, 80 grams of nickel powder, 80 grams of aluminum-magnesium alloy, 150 grams of micro-carbon ferrochromium, and 80 grams of ferromolybdenum , 120 grams of ferrovanadium. Put all the raw materials into the mixer and mix for 30 minutes, then take 500 grams and add them to the U-shaped channel steel belt; close the U-shaped groove so that the drug core powder is wrapped in it and flattened, and rolled into a U-shaped groove again, and the remaining 500 The core powder is added to the U-shaped channel steel belt, and then drawn and reduced one by one by a wire drawing machine, so that the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com