Ultra-high molecular weight polysiloxane synthesis method

A technology of ultra-high molecular weight polysiloxane, which is applied in the field of polymer materials, can solve the problems of unstable rubber materials, many low-molecular polymers, and slow equilibrium reactions, so as to achieve less residual impurities, good product performance, non-degradable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

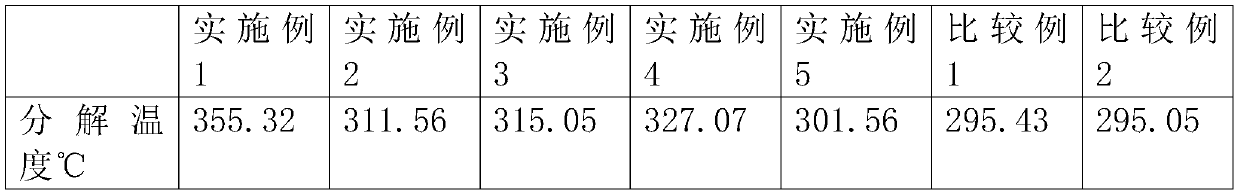

Examples

Embodiment 1

[0030] Put 1,000kg of hydroxyl-terminated polydimethylsiloxane with a viscosity of 5,000mpa.s into a stainless steel reactor and raise the temperature to 120°C. Under 1-2ml / min nitrogen flow, start dehydration treatment for 1 hour, then cool down, and add it to a 2,000-liter kneader , add 100 grams (containing 0.00002 grams of LPNC) of linear chlorinated phosphazene silicone oil solution below 80°C, the material starts to turn white after 10 minutes, the viscosity rises sharply, maintain the temperature at 120°C, and under the negative pressure of 0.06mpa lower than the atmospheric pressure React for 2 hours, release the vacuum, continue to heat up to 230°C, and stir and mix for 3 hours to make the catalyst invalid.

[0031] GPC (gel permeation chromatography) determined Mw 1200000 g / mol.

[0032] 170 ℃ vacuum oven for 2 hours, the volatile content is 0.05%, the color of the glue is transparent, without any smell.

[0033] The product prepared above was mixed with a toluene s...

Embodiment 2

[0036] Put 1,000kg of hydroxyl-terminated polydimethylsiloxane with a viscosity of 10,000mpa.s into a stainless steel reactor and heat up to 130°C. Under 1-2ml / min nitrogen flow, start dehydration treatment for 1 hour, then cool down, and add it to a 2,000-liter kneader , add 150 grams (containing 0.00003 grams of LPNC) of linear chlorinated phosphazene silicone oil solution below 80°C, the material starts to turn white after 5 minutes, the viscosity rises sharply, maintain the temperature at 100°C, and under the negative pressure of 0.1mpa lower than the atmospheric pressure React for 4 hours, release the vacuum, continue to heat up to 250° C., stir and mix for 2 hours, decompose the catalyst, and terminate the reaction.

[0037] GPC determined Mw 1800000 g / mol.

[0038] 170 ℃ vacuum oven for 2 hours, the volatile content is 0.08%, the color of the glue is transparent, without any smell.

[0039] The product prepared above was mixed with a toluene solution to prepare a tolue...

Embodiment 3

[0042] Put 2,000kg of hydroxyl-terminated polydimethylsiloxane with a viscosity of 3,000mpa.s into a stainless steel reactor and heat up to 115°C. Under 1-2ml / min nitrogen flow, start dehydration treatment for 1 hour, then cool down, and add it to a 3,000-liter kneader. Add 130 grams (including 0.000013 grams of LPNC) of linear chlorinated phosphazene silicone oil solution below 80°C. After 7 minutes, the material starts to turn white, and the viscosity rises sharply. Maintain the temperature at 118°C and react under negative pressure 0.06mpa lower than atmospheric pressure. After 3 hours, the vacuum was released, and the temperature was raised to 240° C. for 2 hours to decompose linear phosphazene chloride and terminate the reaction.

[0043] GPC determined Mw 600000 g / mol.

[0044] 170 ℃ vacuum oven for 2 hours, the volatile content is 0.028%, the color of the glue is transparent, without any smell.

[0045]The product prepared above was mixed with a toluene solution to pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com