Application of phosphorus-doped titanium dioxide nanotube array catalyst in photoelectrocatalytic degradation of tylosin

A technology of nanotube arrays and titanium dioxide, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of poor photocatalytic efficiency, achieve good photocurrent density, simple synthesis process, Good effect of recycling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1), using 50ml 18wt.% NH 4 F, 12ml 30% H 2 o 2 and 3ml of 18wt.% urea and added 12ml of concentrated HNO 3 The polishing solution is used to polish the 2*5cm titanium sheet.

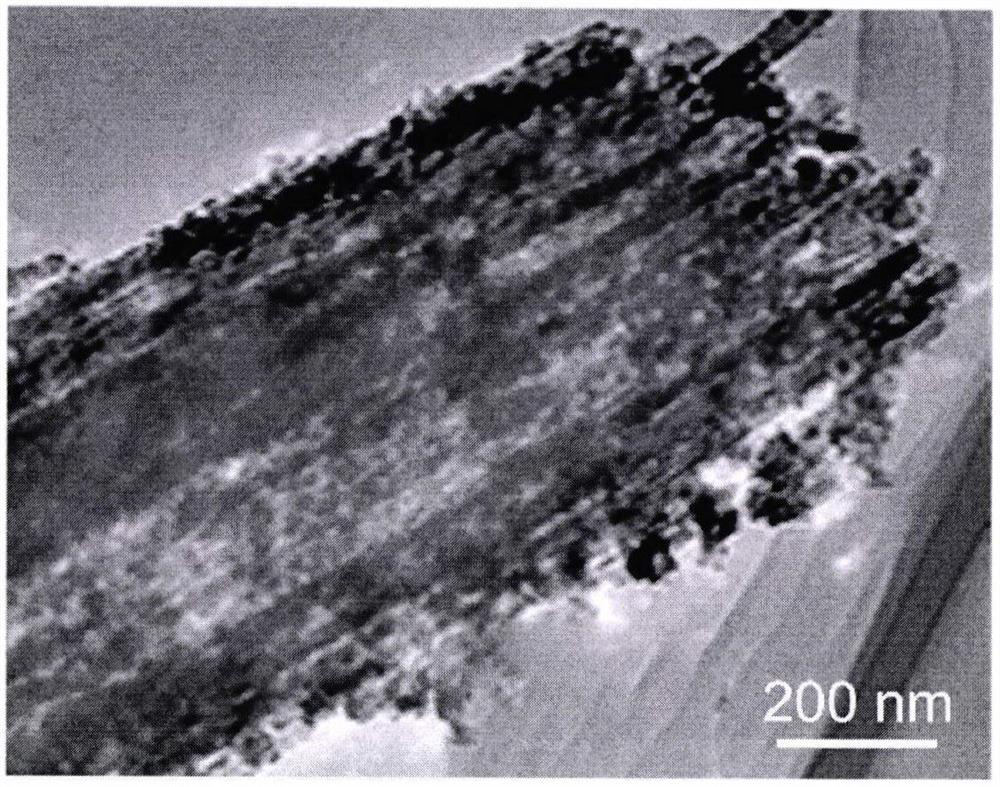

[0025] (2), the polished titanium sheet in step (1) is used as the anode, and the platinum foil is used as the cathode, and a two-electrode system is used to carry out the first step of anodic oxidation, and the electrolyte is composed of 0.4wt.% NH 4 F, 2% volume fraction of deionized water and 98% volume fraction of ethylene glycol, oxidation voltage 40V, oxidation time 1 hour.

[0026] (3), the titanium sheet in the step (2) is placed in 30% H 2 o 2 Sonicate for 13 minutes until a bright surface appears.

[0027] (4) Carry out the second step anodic oxidation to the titanium sheet in the step (3), the oxidation voltage is 50V, and the oxidation time is 1.5 hours.

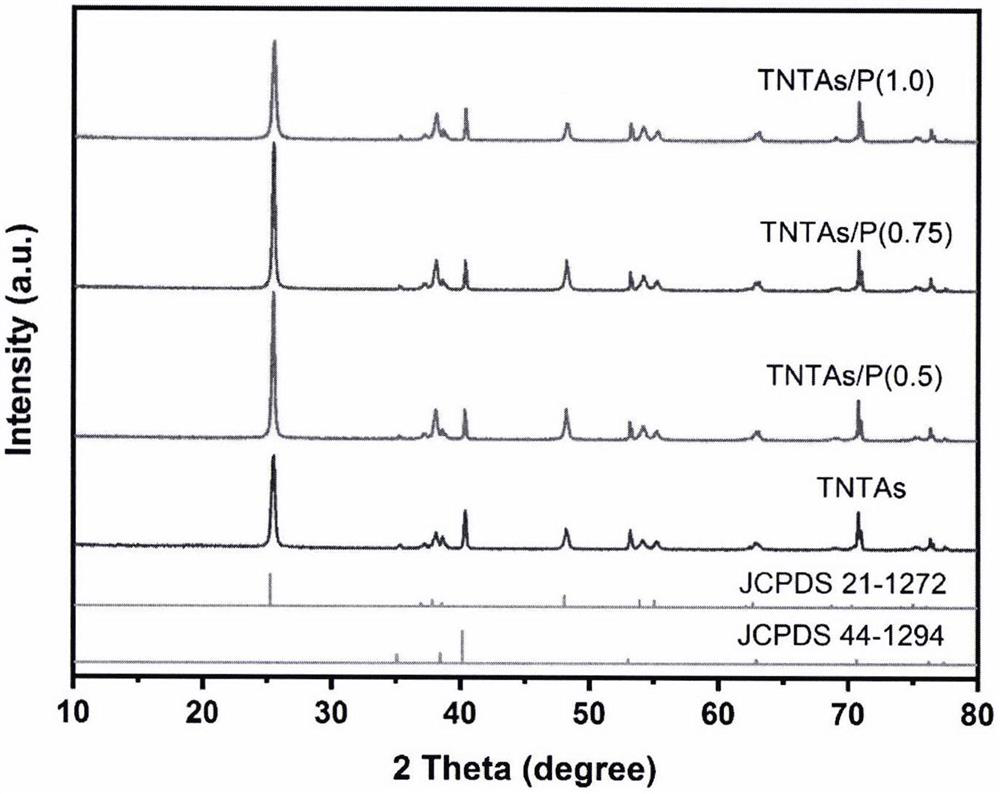

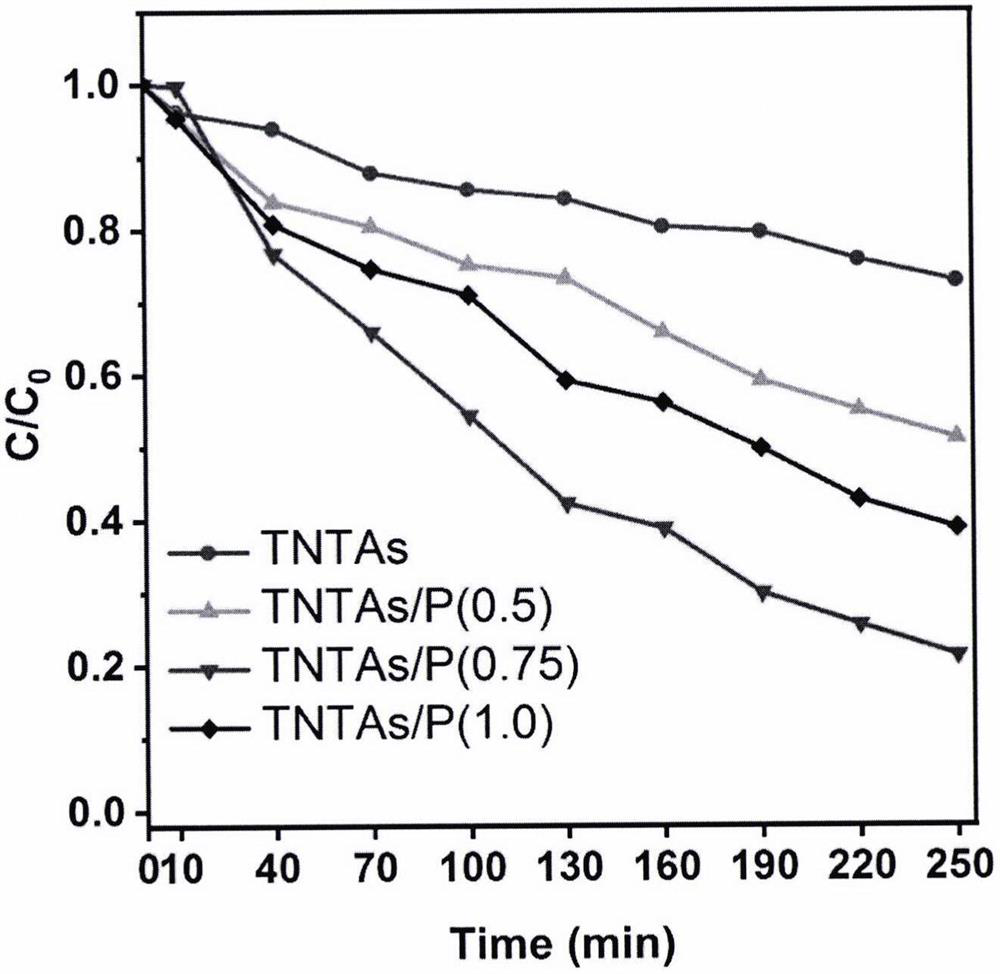

[0028] (5) The titanium sheet prepared in step (4) was washed with deionized water and dried in air, and then annealed in a...

Embodiment 2

[0033] (1), using 50ml 18wt.% NH 4 F, 12ml 30% H 2 o 2 and 3ml of 18wt.% urea and added 12ml of concentrated HNO 3 The polishing solution is used to polish the 2*5cm titanium sheet.

[0034] (2), the polished titanium sheet in step (1) is used as the anode, and the platinum foil is used as the cathode, and a two-electrode system is used to carry out the first step of anodic oxidation, and the electrolyte is composed of 0.4wt.% NH 4 F, 2% volume fraction of deionized water and 98% volume fraction of ethylene glycol, oxidation voltage 40V, oxidation time 1 hour.

[0035] (3), the titanium sheet in the step (2) is placed in 30% H 2 o 2 Sonicate for 13 minutes until a bright surface appears.

[0036] (4) Carry out the second step anodic oxidation to the titanium sheet in the step (3), the oxidation voltage is 50V, and the oxidation time is 1.5 hours.

[0037] (5) The titanium sheet prepared in step (4) was washed with deionized water and dried in air, and then annealed in a...

Embodiment 3

[0042] (1), using 50ml 18wt.% NH 4 F, 12ml 30% H 2 o 2 and 3ml of 18wt.% urea and added 12ml of concentrated HNO 3 The polishing solution is used to polish the 2*5cm titanium sheet.

[0043] (2), the polished titanium sheet in step (1) is used as the anode, and the platinum foil is used as the cathode, and a two-electrode system is used to carry out the first step of anodic oxidation, and the electrolyte is composed of 0.4wt.% NH 4 F, 2% volume fraction of deionized water and 98% volume fraction of ethylene glycol, oxidation voltage 40V, oxidation time 1 hour.

[0044] (3), the titanium sheet in the step (2) is placed in 30% H 2 o 2 Sonicate for 13 minutes until a bright surface appears.

[0045] (4) Carry out the second step anodic oxidation to the titanium sheet in the step (3), the oxidation voltage is 50V, and the oxidation time is 1.5 hours.

[0046] (5) The titanium sheet prepared in step (4) was washed with deionized water and dried in air, and then annealed in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com