Surface silicon oxidation polyimide-co-silane thin film and preparation method thereof

A silicon oxidation polyimide, polyimide technology, applied in the direction of chemical instruments and methods, flat products, other household appliances, etc., can solve the problem of increased material adhesion, cold welding phenomenon has not been better resolved, and affects Problems such as the normal function of the spacecraft mechanism, to achieve the effect of excellent product performance and controllable process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

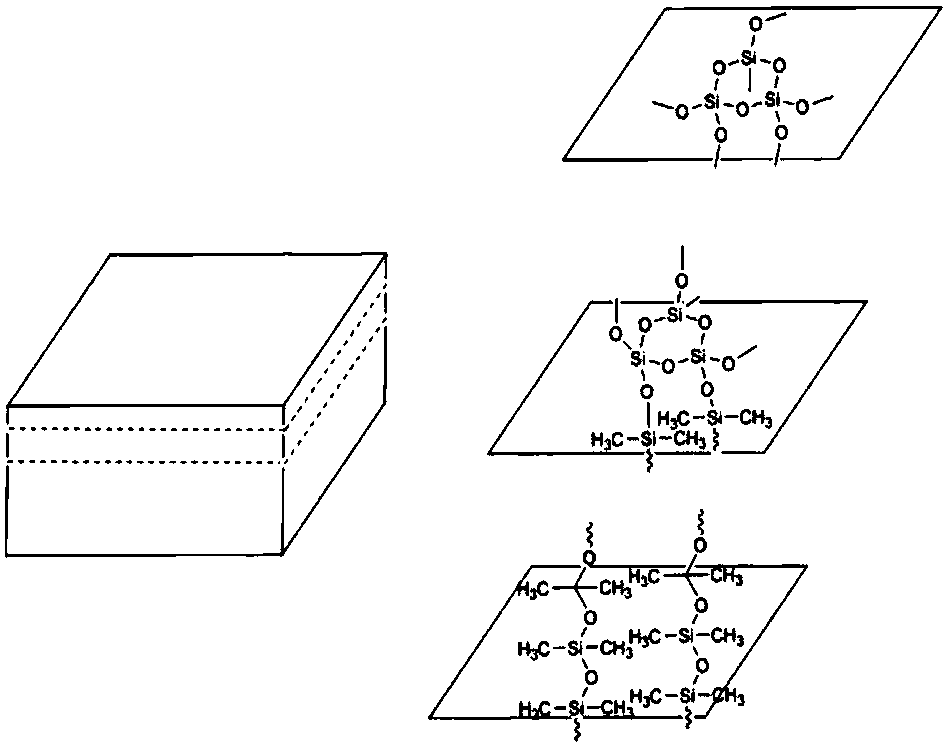

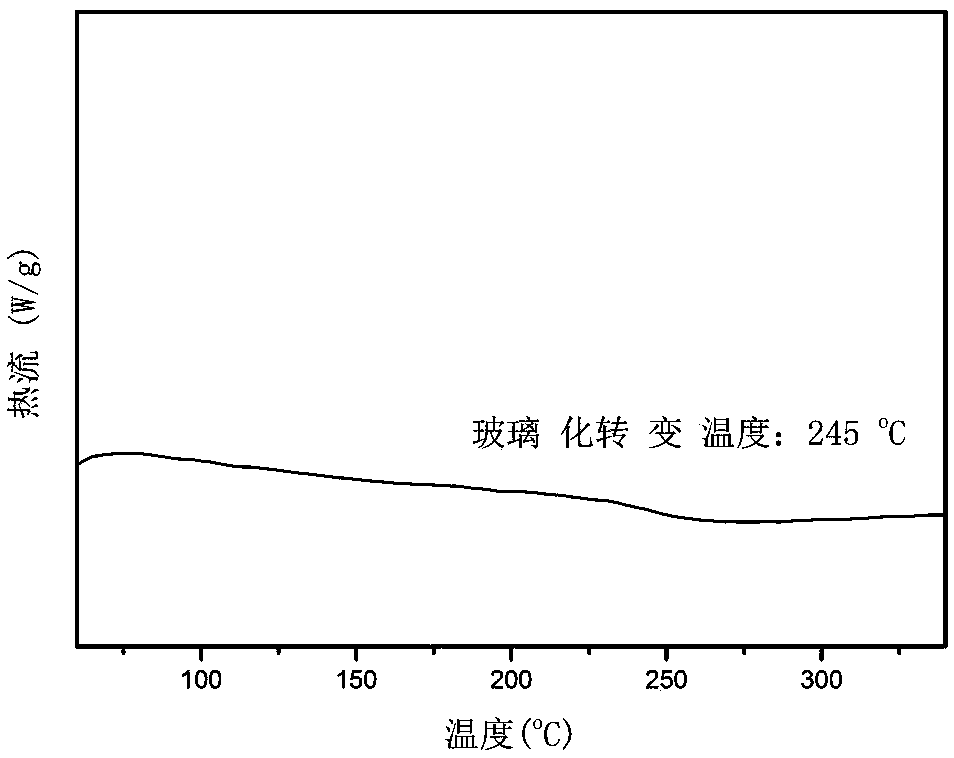

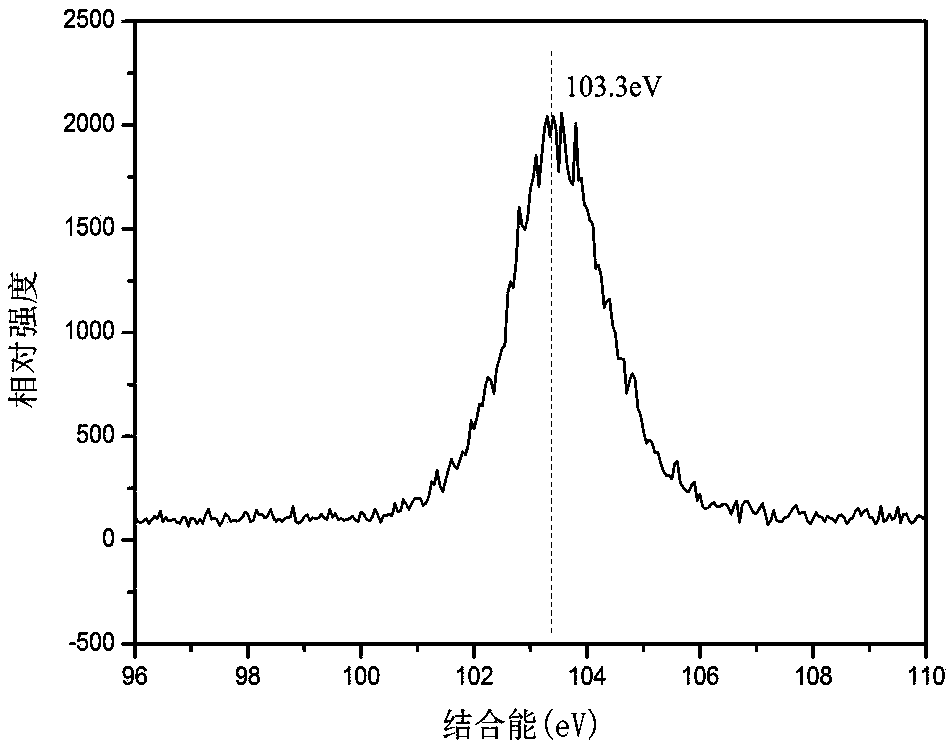

Method used

Image

Examples

Embodiment 1

[0028] (1) At room temperature and under the protection of nitrogen, 2.94g 3,3,4',4'-biphenyltetraacid dianhydride was dissolved in 55.86g N,N-dimethylformamide (DMF), and the solid content was 5%, stirred for 5 hours to obtain 3,3,4',4'-biphenyltetraacid dianhydride solution;

[0029] (2) Under nitrogen protection, 0.78 g of diaminopolysiloxane with a molecular weight of 860 was dissolved in 14.82 g of tetrahydrofuran with a solid content of 5%, and stirred for 5 hours to obtain a diaminopolysiloxane tetrahydrofuran solution;

[0030] (3) Slowly add the diaminopolysiloxane tetrahydrofuran solution dropwise into the 3,3,4',4'-biphenyltetraacid dianhydride solution, stir for 6 hours and then add 1.82g of 4,4 '-diaminodiphenyl ether and 34.58g N,N-dimethylformamide (DMF), stirred for 4 hours to obtain oligomeric polyamic acid siloxane solution 1;

[0031] (4) Transfer the oligomeric polyamic acid-co-siloxane solution 1 into an autoclave, replace the air with nitrogen, pressuriz...

Embodiment 2

[0039] (1) Dissolve 2.94g of 3,3,4',4'-biphenyltetralic acid dianhydride in 14.70g of N,N-dimethylacetamide (DMAc) at room temperature and under the protection of nitrogen, with a solid content of 20%, stirred for 3 hours under nitrogen to obtain a solution of 3,3,4',4'-biphenyltetralic acid dianhydride;

[0040] (2) Under the protection of nitrogen, 21 g of diaminopolysiloxane with a molecular weight of 2100 was dissolved in 84 g of tetrahydrofuran with a solid content of 20%, and stirred for 3 hours under nitrogen to obtain a solution of diaminopolysiloxane in tetrahydrofuran;

[0041] (3) Slowly add the diaminopolysiloxane tetrahydrofuran solution dropwise into the aromatic tetraacid dianhydride solution to obtain oligomeric polyamic acid-co-siloxane solution 2;

[0042] (4) Transfer the oligomeric polyamic acid-co-siloxane solution 2 into an autoclave, replace the air with nitrogen, pressurize to 0.14MPa, keep at 60°C for 3 hours, and keep at 100°C for 3 hours, Cool to ro...

Embodiment 3

[0047] (1) At room temperature and under the protection of nitrogen, 2.18g of pyromellitic dianhydride was dissolved in 19.08g of N-methylpyrrolidone (NMP), with a solid content of 10%, and stirred for 4h under nitrogen to obtain a pyromellitic dianhydride solution ;

[0048] (2) Under the protection of nitrogen, 1.48g of diaminopolysiloxane with a molecular weight of 950 was dissolved in 13.32g of tetrahydrofuran with a solid content of 10%, and stirred for 4 hours under nitrogen to obtain diaminopolysiloxane tetrahydrofuran solution ;

[0049] (3) Slowly add the diaminopolysiloxane tetrahydrofuran solution dropwise into the aromatic tetraacid dianhydride solution, stir for 4 hours and add 3.46g of 2,2-bis[4-(4-aminobenzene Oxygen) phenyl] propane and 31.14g N-methylpyrrolidone (NMP), stirred for 4 hours to obtain oligomeric polyamic acid-co-siloxane solution 3;

[0050] (4) Transfer the oligomeric polyamic acid-co-siloxane solution 3 into an autoclave, replace the air with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com