Modified polyurethane/unsaturated polyester resin dibasic alcohol preparation method

A technology of polyester diol and polyester resin is applied in the field of preparation of flexible unsaturated polyester diol, which can solve the problems of high preparation cost, complicated operation and cumbersome operation, and achieve excellent product performance and controllable curing process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

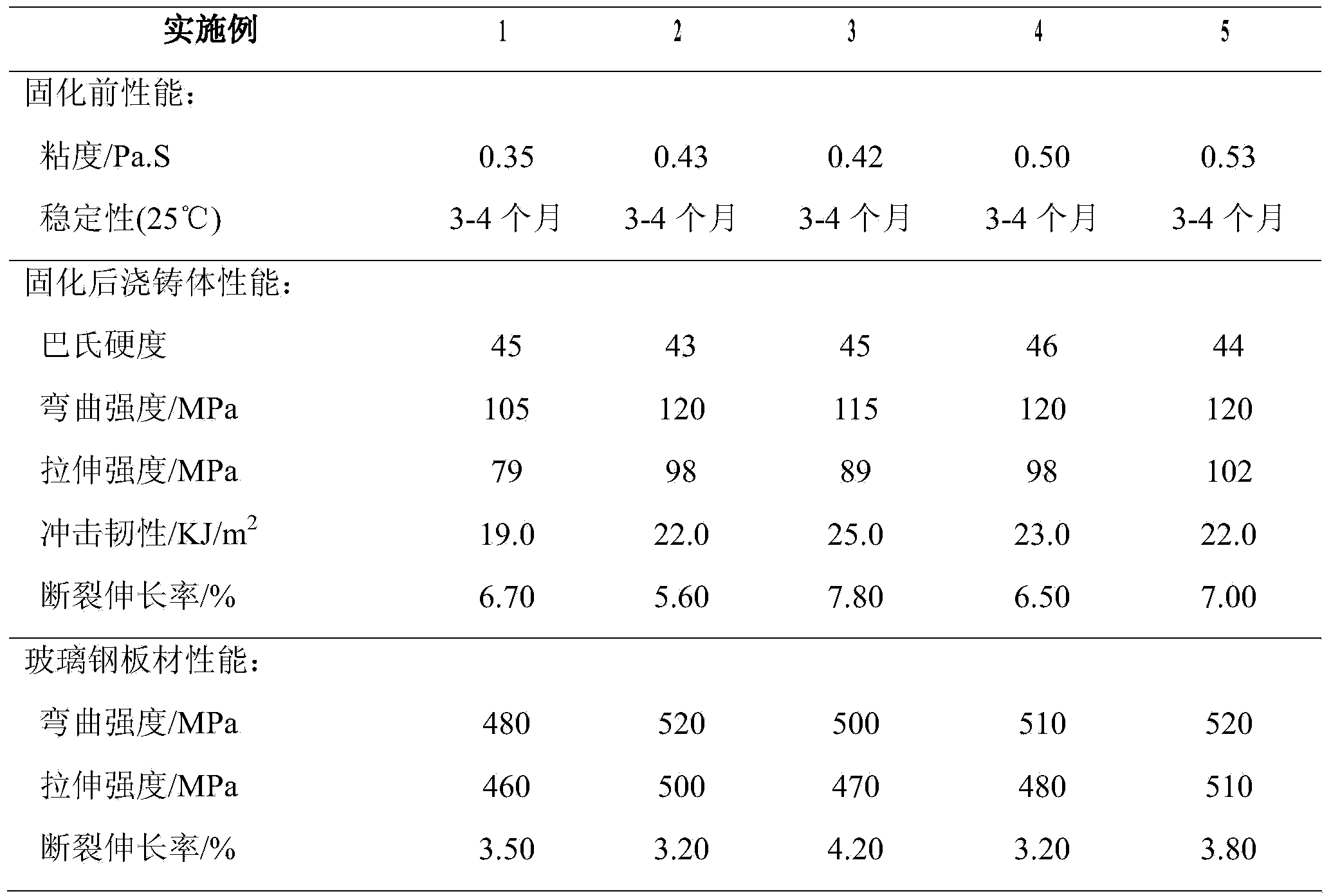

Examples

Embodiment 1

[0020] The aggregation steps are as follows:

[0021] 1. Preparation of polyester resin prepolymer:

[0022] Add propylene glycol and raise the temperature to 80°C; add isophthalic acid (the molar ratio of glycol to saturated dibasic acid is 1-1.05:1). Raise the temperature to 150°C within 1 hour, and then raise the temperature to 210°C at a heating rate of 10°C / h. Condensate and polymerize at 180°C for 3 hours under nitrogen gas, and cool down to 180°C when the acid value is less than 20mgKOH / g.

[0023] 2. Preparation of flexible unsaturated polyester diol:

[0024] Add again 0.1 moles of hydroxyl-terminated polybutadiene with a molecular weight of 1200, 1.2 moles of diethylene glycol, and 1 mole of maleic anhydride (the flexible macromolecular diol of the hydroxyl group: the mole of dibasic alcohol and unsaturated dibasic acid The ratio is 0.1:1.2:1). Raise the temperature to 210°C at a heating rate of 10°C / h, and use polycondensation to copolymerize hydroxyl-terminated...

Embodiment 2

[0028] The aggregation steps are as follows:

[0029] 1. Preparation of polyester resin prepolymer:

[0030] Add 1.03 moles of propylene glycol and raise the temperature to 80°C; add 1 mole of terephthalic acid (the molar ratio of glycol to saturated dibasic acid is 1.03:1). Raise the temperature to 150°C within 1 hour, and then raise the temperature to 210°C at a heating rate of 10°C / h. Condensate and polymerize at 180°C for 3 hours under nitrogen gas, and cool down to 180°C when the acid value is less than 20mgKOH / g.

[0031] 2. Preparation of flexible unsaturated polyester diol:

[0032] Add again 0.2 moles of hydroxyl-terminated styrene-butadiene liquid rubber with a molecular weight of 2000, 1.5 moles of diethylene glycol, and 1 mole of maleic anhydride (the flexible macromolecular diol of the hydroxyl group: the mole of dibasic alcohol and unsaturated dibasic acid The ratio is 0.2:1.5:1). Raise the temperature to 210°C at a heating rate of 10°C / h, and use polycondens...

Embodiment 3

[0036] The aggregation steps are as follows:

[0037] 1. Preparation of polyester resin prepolymer:

[0038] Add 1.05 moles of butanediol and raise the temperature to 80°C; add 1 mole of phthalic anhydride (the molar ratio of dihydric alcohol to saturated dibasic acid is 1.05:1). Raise the temperature to 150°C within 1 hour, and then raise the temperature to 210°C at a heating rate of 10°C / h. Condensate and polymerize at 180°C for 3 hours under nitrogen gas, and cool down to 180°C when the acid value is less than 20mgKOH / g.

[0039] 2. Preparation of flexible unsaturated polyester diol:

[0040]Add again 0.15 moles of hydroxyl-terminated hydrogenated polybutadiene with a molecular weight of 1500, 1.4 moles of diethylene glycol, and 1 mole of maleic anhydride (the hydroxyl-terminated flexible macromolecular diol: dibasic alcohol and unsaturated dibasic acid) The molar ratio is 0.15:1.4:1). Raise the temperature to 210°C at a heating rate of 10°C / h, and use polycondensation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com