Preparation and application method of silicon carbide material for repairing heavy equipment of thermal power plant

A technology for heavy-duty equipment and application methods, applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of low bonding strength of composite materials, difficult control of repaired thickness, thermal deformation of impeller blades, etc., to eliminate the surface of workpieces Stress, excellent wear resistance and bonding performance, the effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The invention provides a method for preparing a silicon carbide epoxy resin composite material for repairing superhard materials for heavy equipment in a thermal power plant, comprising the following steps:

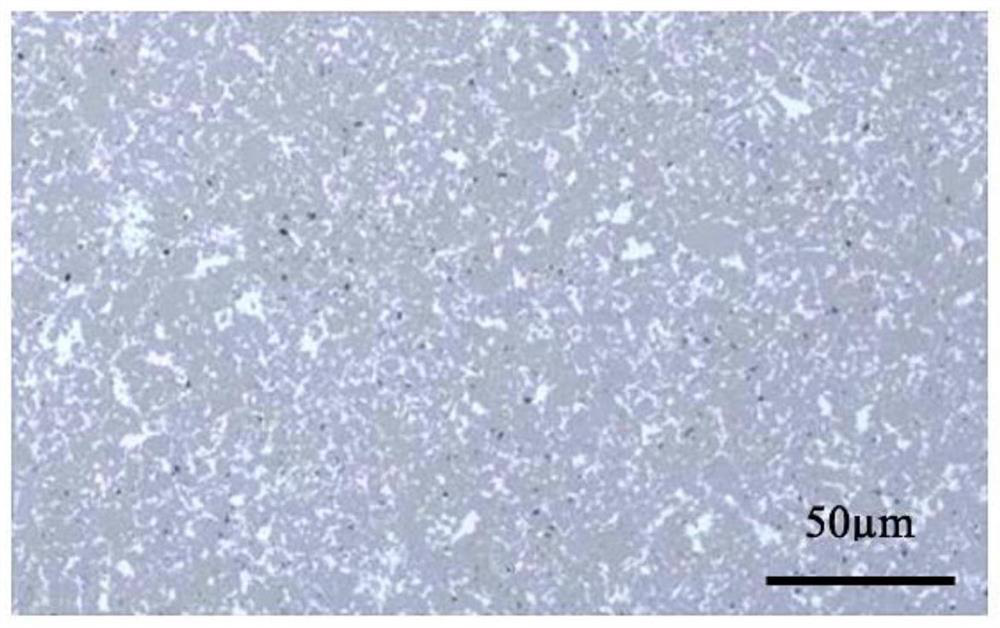

[0045] Step 1) Vacuum stirring: SiC and epoxy resin are stirred and mixed in a vacuum environment, wherein the ratio of silicon carbide to epoxy resin is 50-80:20-50, and the vacuum environment is in a vacuum mixing tank with high-speed rotating blades carried out in;

[0046] Step 2) Vacuum casting: Control the temperature in the spherical vacuum container at 50-70°C, place the casting mold in the spherical vacuum container, pump out the air in the spherical vacuum container until the vacuum degree is lower than 0.5T, and then seal the spherical vacuum container; In step 1), the material outlet of the vacuum mixing tank that has completed the vacuum stirring is connected with the tundish feed port of the spherical vacuum container, and after the connection is seal...

Embodiment

[0074] A silicon carbide composite material for repairing superhard materials for heavy equipment in thermal power plants and its application method when repairing heavy machinery parts,

[0075] Specifically include the following steps;

[0076] Step 1) Vacuum stirring: Stir and mix silicon carbide and epoxy resin in a vacuum environment, wherein the ratio of silicon carbide and epoxy resin is 80:20, and the vacuum environment is carried out in a vacuum stirring tank with high-speed rotating blades; Epoxy resin is selected from polyethylene glycol dioxirane methyl ether;

[0077] Step 2) Vacuum casting: Control the temperature in the spherical vacuum container at 60°C, place the casting mold in the spherical vacuum container, pump out the air in the casting mold until the vacuum degree is lower than 0.5T, and then seal the spherical vacuum container; put step 1) The material outlet of the vacuum stirring tank that completes the vacuum stirring in the process is connected wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com