Method of removing hard coating film

A hard coating and stripping technology, which is applied in the coating, metal material coating process, ion implantation plating, etc., can solve the problem of reduced cutting performance, adhesion damage, and inability to obtain coating performance (durability and wear resistance) To avoid problems such as damage, achieve the effect of improving adhesion strength, inhibiting fragility, reducing shape changes and dimensional changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] Embodiments of the present invention will be described below with reference to the drawings.

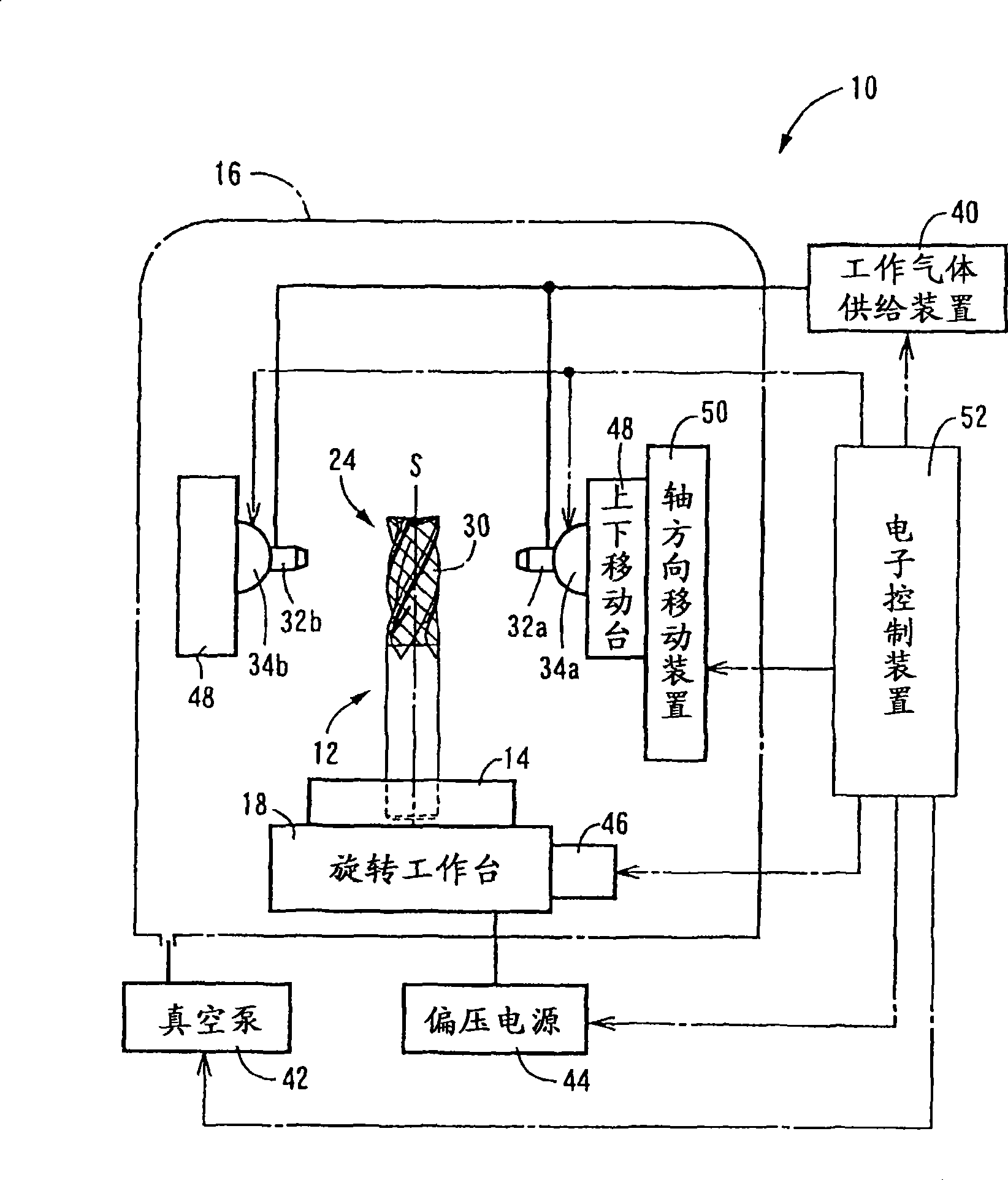

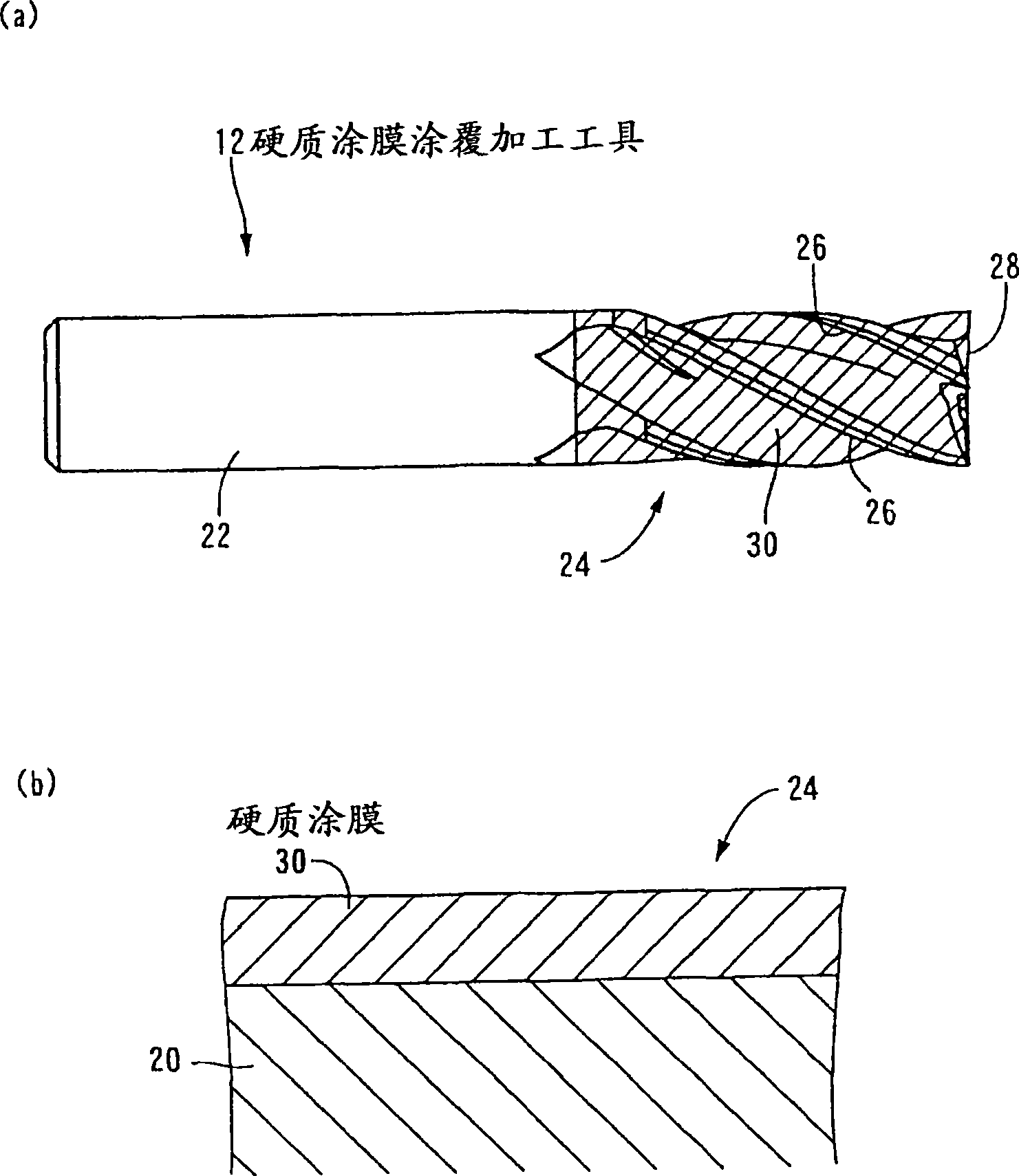

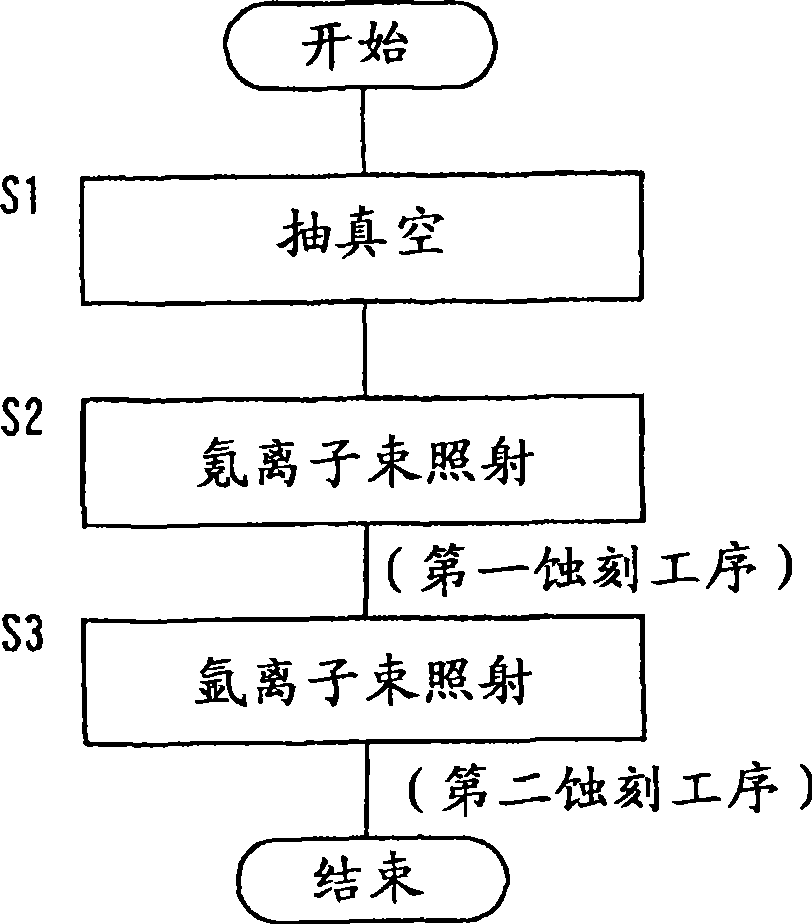

[0038] figure 1 It is a schematic configuration diagram of a hard coating film stripping device 10 that can strip a hard coating film according to the method of the present invention. It utilizes an ion beam etching device, and a hard coating film coating processing tool 12 passes through a chuck 14 to The centerline S thereof is arranged concentrically on the rotary table 18 in the etching processing container 16 . The hard coating film coating processing tool 12 is equivalent to the hard coating film coating part, and the figure shows the situation of the end mill, such as figure 2 As shown, a shank 22 and a blade portion 24 are integrally provided on a tool base material 20 made of cemented carbide. The edge portion 24 is provided with a peripheral edge 26 and a bottom edge 28 as cutting edges, and the surface of the edge portion 24 is coated with a hard coat 30 by PVD c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com