A two-component thermally conductive silica gel sheet and its preparation method and equipment

A heat-conducting silicone sheet, two-component technology, applied in adhesives, sustainable manufacturing/processing, film/sheet adhesives, etc., can solve problems such as waste, environmental pollution, uncontrollable time, etc., to avoid loss and waste , Good overall performance, good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

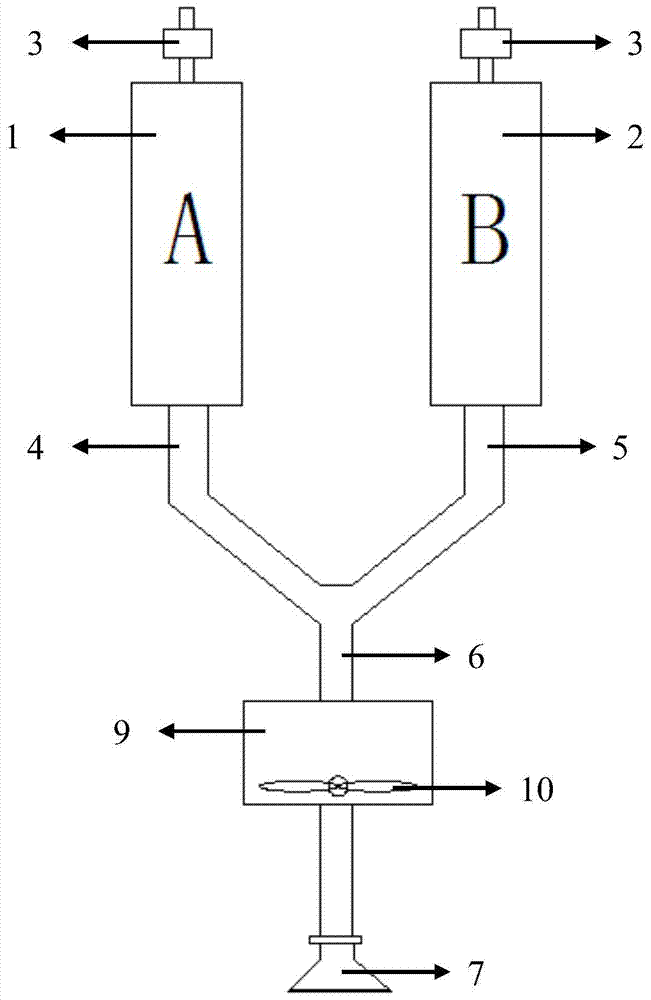

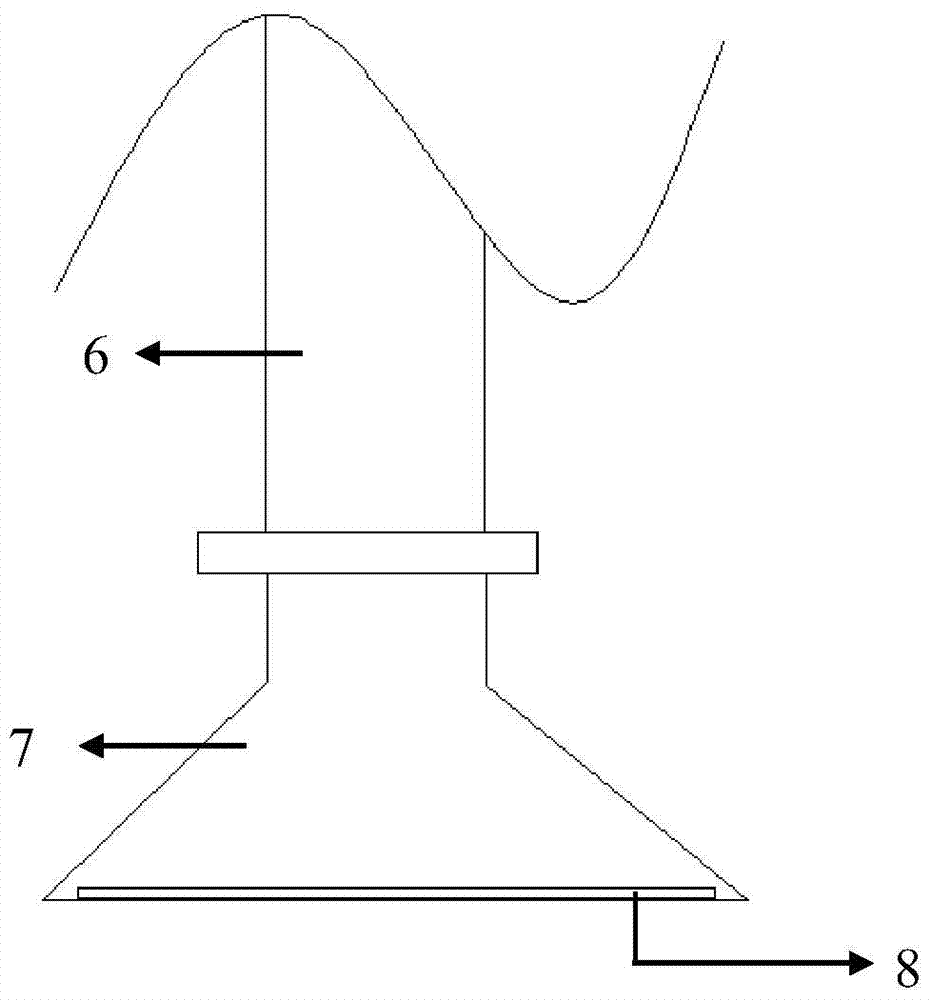

[0066] The preparation of following each embodiment can adopt such as figure 1 and 2 The shown equipment includes a storage tank A1 and a storage tank B2 respectively with a pressurizing mechanism 3, and the storage tank A1 and B2 are respectively connected with a discharge channel A4 and a discharge channel B5, the discharge channel A4 and the discharge channel B5 merge into a mixing channel C6 after a certain distance, and the end of the mixing channel C6 is connected to the discharge port 7. Wherein, the discharge port 7 is a strip-shaped outlet 8 with a controllable width. A mixing tank 9 is also provided on the mixing channel C6, and a stirring or kneading mechanism 10, such as a stirring paddle, may be further provided in the mixing tank 9. The pressurizing mechanism 3 on the material tank A1 and the material storage tank B2 can be an air cylinder. The strip-shaped outlet 8 can be set to a required thickness and width, such as 0.3mm.

[0067] The process of using the...

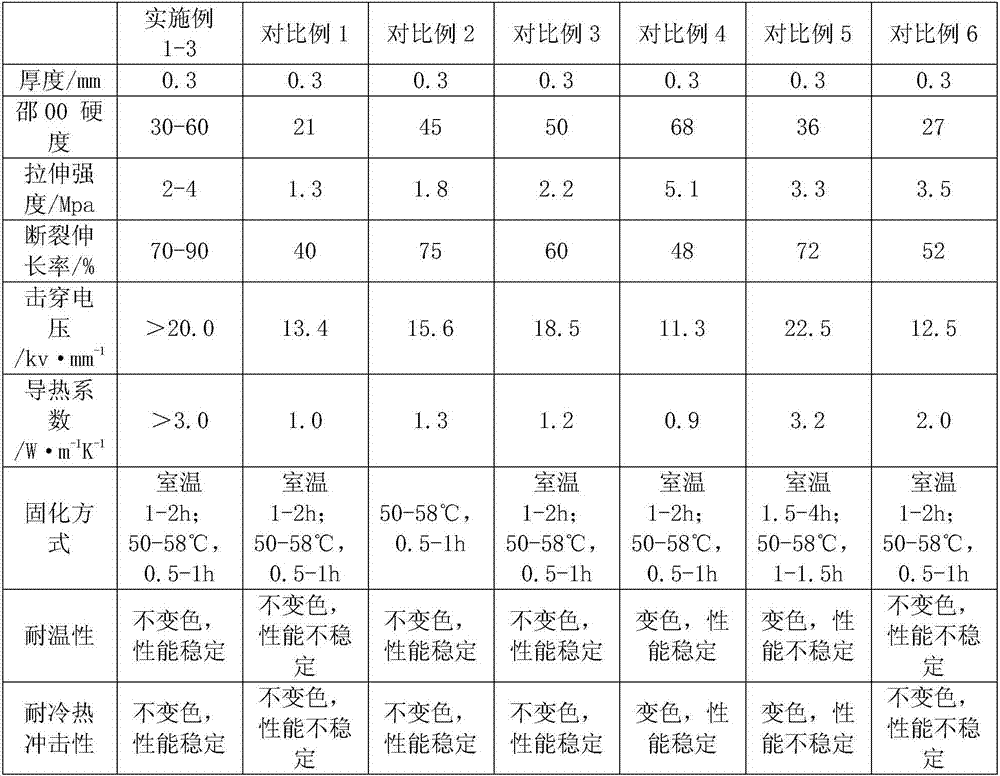

Embodiment 1

[0074] Adopt above-mentioned equipment and method to prepare heat-conducting silica gel sheet, the use situation of raw material is as follows:

[0075] Component A includes:

[0076] a1: 90 parts by weight of divinyl-terminated dimethylpolysiloxane, the viscosity of which is 2000cps, the average molecular weight is 600,000, and the average mass percentage of vinyl is 0.2%;

[0077] a2: 40 parts by weight of dihydroxypropyl-terminated polysiloxane with a viscosity of 5000 cps and an average molecular weight of 10,000;

[0078] a3: 30 parts by weight of a copolymer of dihydroxy-terminated dimethyl siloxane and methyl vinyl siloxane, the mass content of hydroxyl is 4%; the mass content of methyl vinyl siloxane is 30%;

[0079] a4: 3 parts by weight of hexamethylhexavinylcyclohexasiloxane;

[0080] a5: 150 parts by weight of silicon nitride, particle size 20 μm;

[0081] a6: 5 parts by weight of γ-(2,3-epoxypropoxy)propyltrimethoxysilane;

[0082] Component B includes:

[00...

Embodiment 2

[0088] Adopt above-mentioned equipment and method to prepare heat-conducting silica gel sheet, the use situation of raw material is as follows:

[0089] Component A includes:

[0090] a1: 95 parts by weight of bisallyl-terminated dimethyl polysiloxane, the viscosity of which is 1500 cps, the average molecular weight is 800,000, and the average mass percentage of vinyl is 0.5%;

[0091] a2: 20 parts by weight of dihydroxypropyl-terminated polysiloxane with a viscosity of 3000 cps and an average molecular weight of 6,000;

[0092] a3: 30 parts by weight of a copolymer of dihydroxy-terminated dimethyl siloxane and methyl vinyl siloxane, the mass content of hydroxyl is 4%; the mass content of methyl vinyl siloxane is 30%;

[0093] a4: 2 parts by weight of hexamethylhexavinyl cyclohexasiloxane;

[0094] a5: 160 parts by weight of a mixture of zinc oxide and magnesium oxide, with a particle size of 50 μm;

[0095] a6: 5 parts by weight of γ-(2,3-epoxypropoxy)propyltrimethoxysilan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com