Unsaturated polyester resin for coating and preparation method thereof

A polyester resin and unsaturated technology, which is applied in the field of unsaturated polyester resin for coating and its preparation, can solve the problems that the gel time and the surface drying time cannot be perfectly matched, the production efficiency is affected, and the desktop is easy to shrink. Controllable curing process, good mechanical properties, smooth surface without shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Coating unsaturated polyester resin of the present invention, its preparation method comprises the steps:

[0051] (1) Add ethylene glycol and fumaric acid into the reactor at a molar ratio of 1:1 for polycondensation reaction, raise the temperature to 160°C, keep warm until the water comes out, then heat up to 200°C, and continue to keep warm until the acid value is 50mgKOH / g , vacuumize the reactor until the vacuum degree in the reactor is 0.85MPa, react to the acid value of 25mgKOH / g, add hydroquinone to stop the polycondensation reaction, the addition of hydroquinone is 0.02% of the total mass of the reaction substance %, to obtain unsaturated polyester resin, cooled to 130 ℃, for subsequent use;

[0052] (2) adding ethanol in styrene, the mass ratio of styrene and ethanol is 100:1, stirs evenly, obtains styrene mixed solution;

[0053] (3) Slowly add the styrene mixed solution of 100g of step (2) into the unsaturated polyester resin of 1000g of step (1) for diluti...

Embodiment 2

[0056]Coating unsaturated polyester resin of the present invention, its preparation method comprises the steps:

[0057] (1) Add diethylene glycol and phthalic acid into the reactor at a molar ratio of 1:1.05 to carry out polycondensation reaction, heat up to 162°C, keep warm until the water comes out, then heat up to 202°C, continue to keep warm until the acid value is 52mgKOH / g, Vacuumize the reaction kettle until the vacuum in the reaction kettle is 0.84MPa, react until the acid value is 27mgKOH / g, add o-phthaloquinone to stop the polycondensation reaction, and the addition of o-phthaloquinone is 0.04% of the total mass of the reaction substances , to obtain unsaturated polyester resin, lower the temperature to 132°C, and set aside;

[0058] (2) Add ethanol and acrylic acid in styrene, the mass ratio of styrene, ethanol, acrylic acid is 100:30:3, stir well, obtain styrene mixed solution;

[0059] (3) Slowly add the styrene mixed solution of 500g of step (2) into the unsatu...

Embodiment 3

[0062] Coating unsaturated polyester resin of the present invention, its preparation method comprises the steps:

[0063] (1) Add propylene glycol and maleic acid to the reactor at a molar ratio of 1:1.02 to carry out polycondensation reaction, heat up to 161°C, keep warm until the water comes out, then heat up to 201°C, and continue to keep warm until the acid value is 51mgKOH / g. Reactor carries out vacuumizing operation to the vacuum degree in reactor is 0.83MPa, reacts to acid value 26mgKOH / g, adds methyl hydroquinone to stop polycondensation reaction, the add-on of methyl hydroquinone is 0.03% of reaction substance gross mass, Obtain unsaturated polyester resin, cool down to 131°C, and set aside;

[0064] (2) Add ethanol and acrylic acid to styrene, the mass ratio of styrene, ethanol, acrylic acid is 100:3:2, stir well, obtain styrene mixed solution;

[0065] (3) Slowly add the styrene mixed solution of 240g of step (2) into the unsaturated polyester resin of 1200g of ste...

PUM

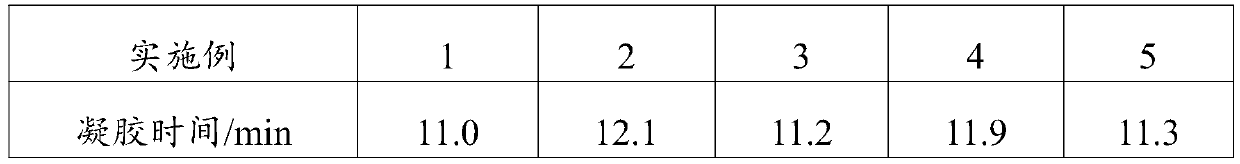

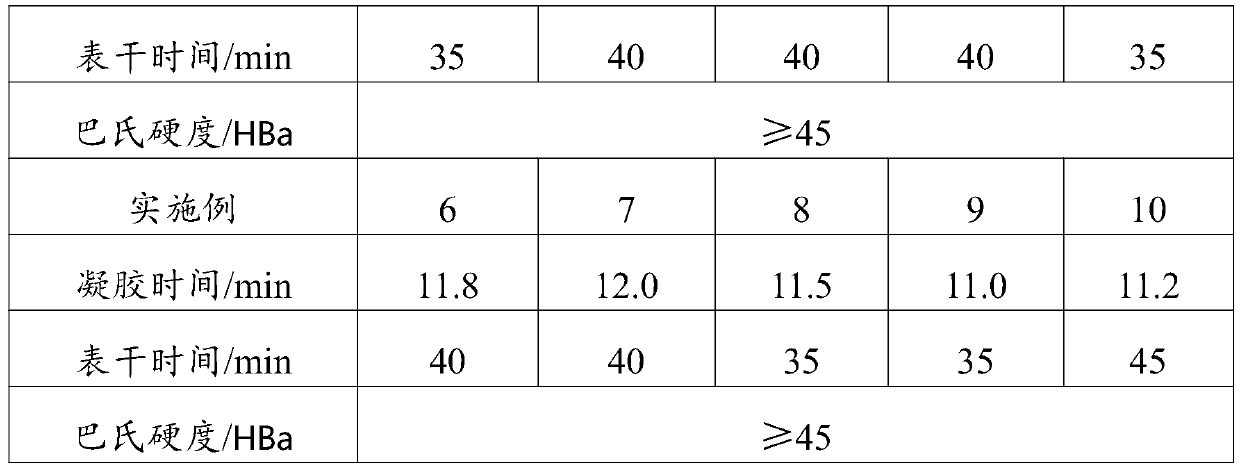

| Property | Measurement | Unit |

|---|---|---|

| gel time | aaaaa | aaaaa |

| tack-free time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com