Water-retaining agent and compound functional fertilizer thereof

A functional, water-retaining agent technology, applied in urea compound fertilizers, alkaline orthophosphate fertilizers, organic fertilizers, etc., can solve problems such as fertilizer loss constraints, low fertilizer utilization rates, and impacts on agricultural production efficiency, and achieve pollution reduction, Improve the utilization rate and increase the effect of crop photosynthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

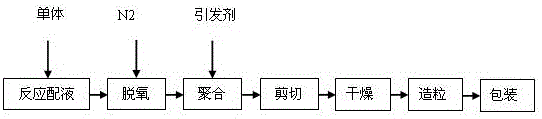

Method used

Image

Examples

Embodiment 1

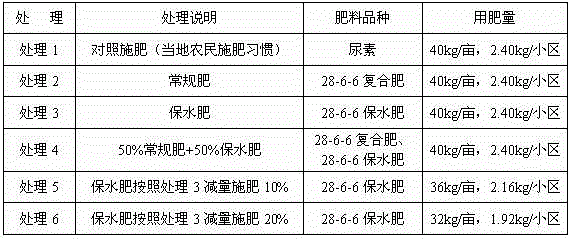

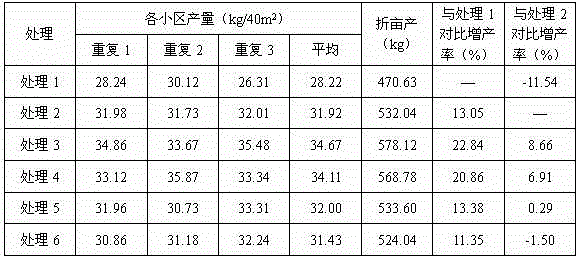

[0041] Water-retaining fertilizer (N-P 2 o 5 -K 2 O: 28-6-6) Preparation method

[0042] Add 20 parts of magnesium sulfate, 70 parts of water retaining agent, 30 parts of borax, and 15 parts of ammonium molybdate according to the weight ratio of the water-retaining components, respectively, the speed of the agitator is 100r / min, and the constant temperature is reacted for 90 minutes to form an environmentally friendly water-retaining material. Then use the drum fluidized bed process to coat the water-retaining material on 300 parts of large-grain urea with a particle size of 2.2-4.2mm to make water-retaining urea. Wherein, the weight ratio of the water-retaining material to the coated granular fertilizer is controlled to be 4:100. Finally, 200 parts of monoammonium phosphate, 350 parts of potassium sulfate and 15 parts of potassium humate were mixed in a certain proportion to make a 28-6-6 water-retaining fertilizer.

Embodiment 2

[0044] Water-retaining fertilizer (N-P 2 o 5 -K 2 O: 26-12-10) Preparation method

[0045] Add 30 parts of magnesium sulfate, 80 parts of water retaining agent, 30 parts of borax, and 15 parts of ammonium molybdate according to the weight ratio of the water-retaining components, respectively, the speed of the agitator is 100r / min, and the constant temperature is reacted for 90min to form an environmentally friendly water-retaining material. Then use the drum fluidized bed process to coat the water-retaining material on 300 parts of large-grain urea with a particle size of 2.2-4.2mm to make water-retaining urea. Wherein, the weight ratio of the water-retaining material to the coated granular fertilizer is controlled to be 4:100. Finally, 230 parts of monoammonium phosphate, 290 parts of potassium sulfate and 45 parts of potassium humate were mixed in a certain proportion to make a 28-12-10 water-retaining fertilizer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com