Method for preparing soybean peptide by immobilized alkaline protease

A technology of soybean polypeptide and protease, which is applied in the direction of protein food processing, plant protein processing, protein food ingredients, etc., can solve the problem of unrecoverable cost and achieve low production cost, mild reaction conditions and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

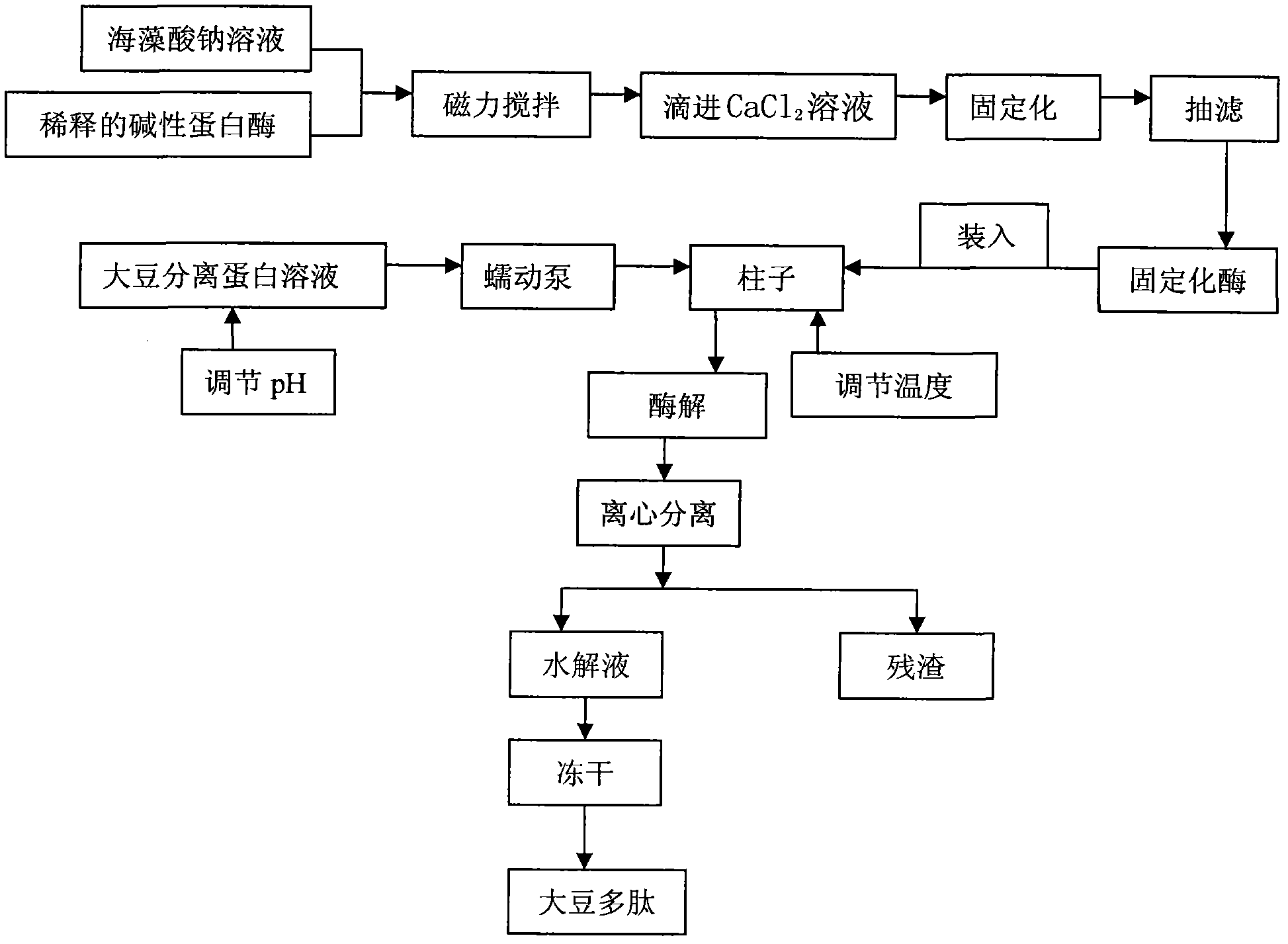

Method used

Image

Examples

experiment example 1

[0030] Experimental example 1 Screening experiment of optimal parameters of soybean protein enzymatic hydrolysis process conditions

[0031] 1 Materials and methods

[0032] 1.1 Materials and reagents

[0033] Soybean Protein Isolate Hargaoke

[0034] protex 6L alkaline protease Danish novo company

[0035] 1.2 Main instruments and equipment

[0036]

[0037]

[0038] 1.3 Experimental method

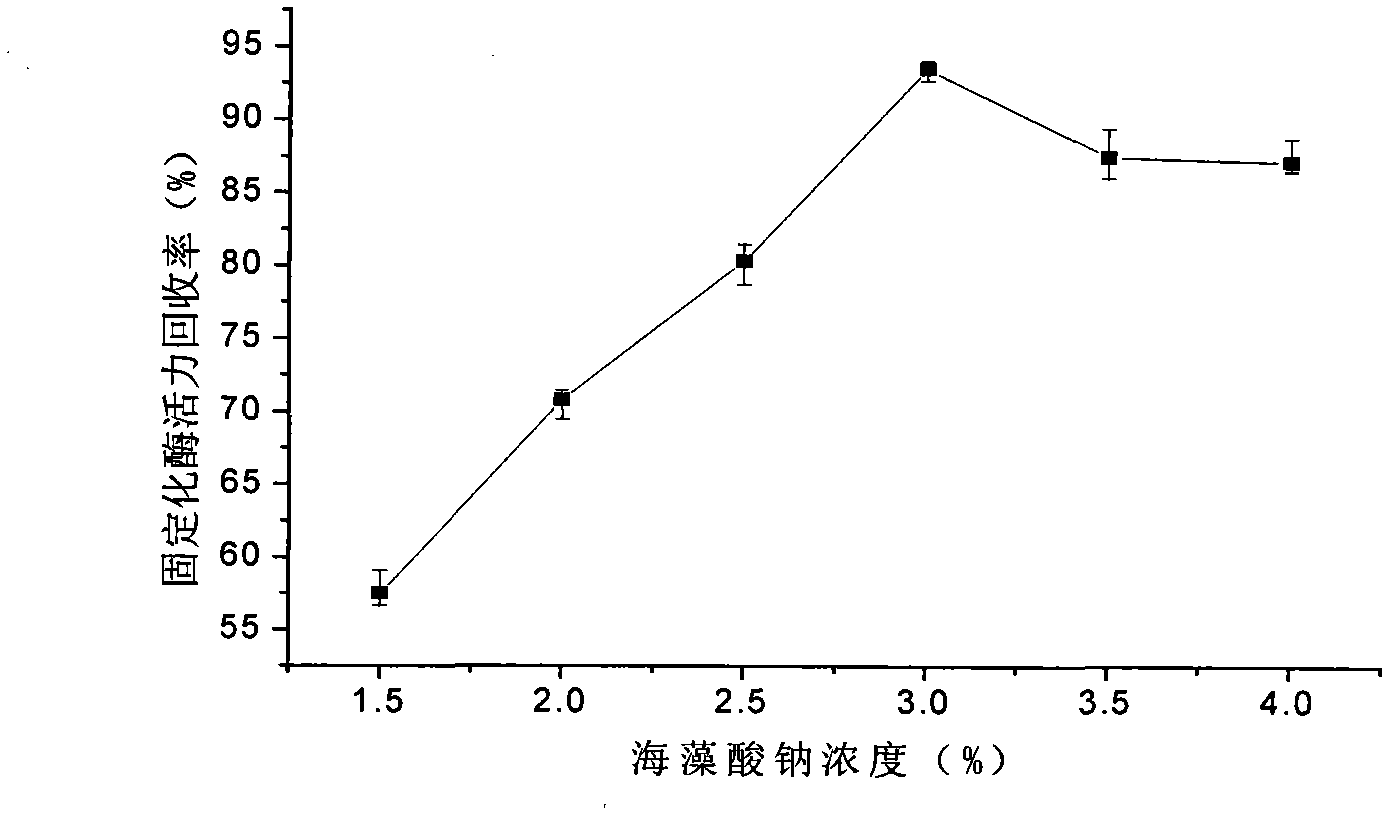

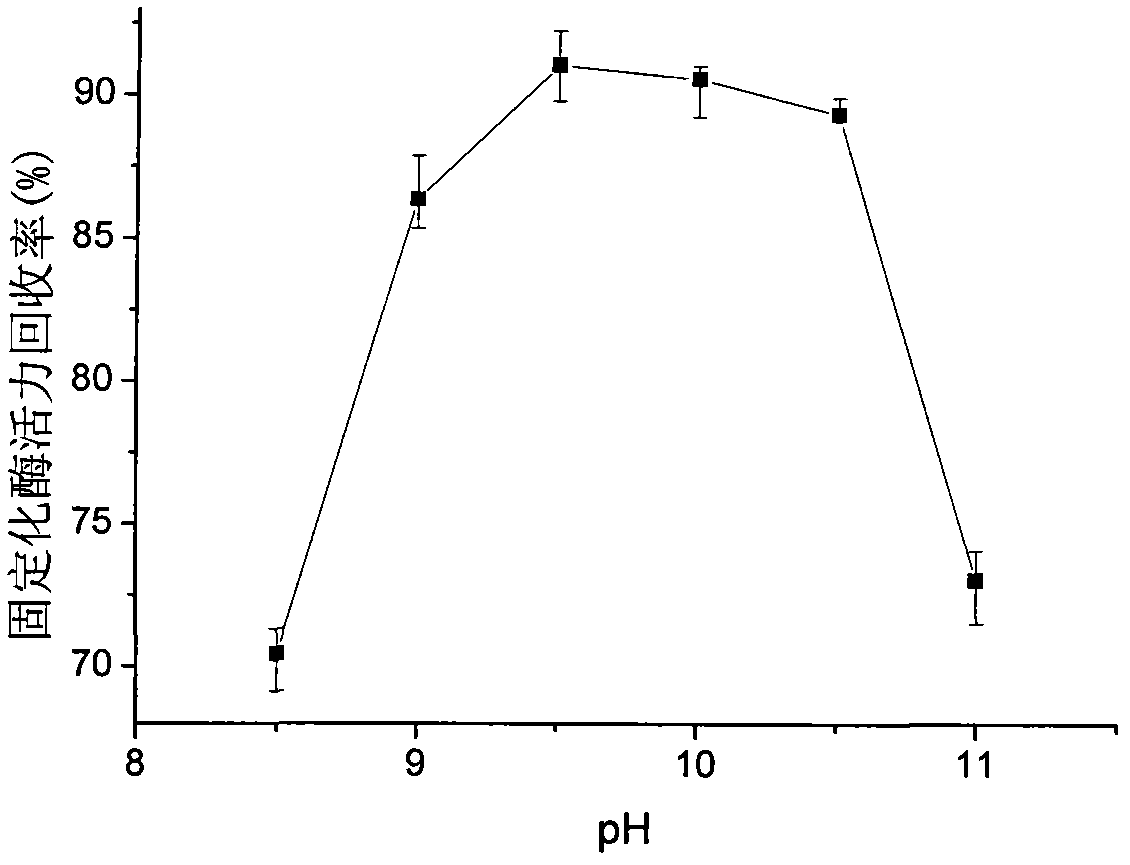

[0039] 1.3.1 Preparation of immobilized alkaline protease

[0040] A certain mass of sodium alginate was weighed in a boric acid buffer solution with a certain pH to prepare sodium alginate solutions with different mass fractions. Measure a certain amount of protex 6L alkaline protease and dilute it with borate buffer. Mix a certain mass fraction of sodium alginate solution with protex 6L in a certain proportion, and after fully stirring evenly, use a peristaltic pump to inject a certain mass fraction of CaCl at a height of 5cm 2 Gel beads were formed in the medium and place...

experiment example 2

[0088] Experimental Example 2 Process parameter optimization experiment for hydrolyzing soybean protein isolate with immobilized alkaline protease packed bed reactor Based on the optimal immobilized alkaline protease process determined in Experimental Example 1, immobilized enzyme was prepared and the packed bed reactor was used to hydrolyze soybean protein isolate , determine the range of hydrolysis process parameters (hydrolysis temperature, pH, hydrolysis time, substrate flow rate), and use the degree of hydrolysis of soybean protein isolate as an investigation index to carry out response surface design.

[0089] 2.1 Materials and reagents

[0090] Soybean Protein Isolate Hargaoke

[0091] Alcalase alkaline protease Danish novo company

[0092] 2.2 Main instruments and equipment

[0093]

[0094] 2.3 Experimental method

[0095] 2.3.1 Packed bed reactor hydrolysis soy protein isolate method

[0096] A soybean protein isolate solution with a concentration of 1% was pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com