Biomass sludge ceramsite as well as preparation method and application thereof

A technology of sludge ceramsite and biomass, which is applied in application, ceramic products, and other household appliances, etc., can solve the problems of secondary pollution, etc., and achieve the effects of reducing production energy consumption and cost, low water absorption, and low calcination temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

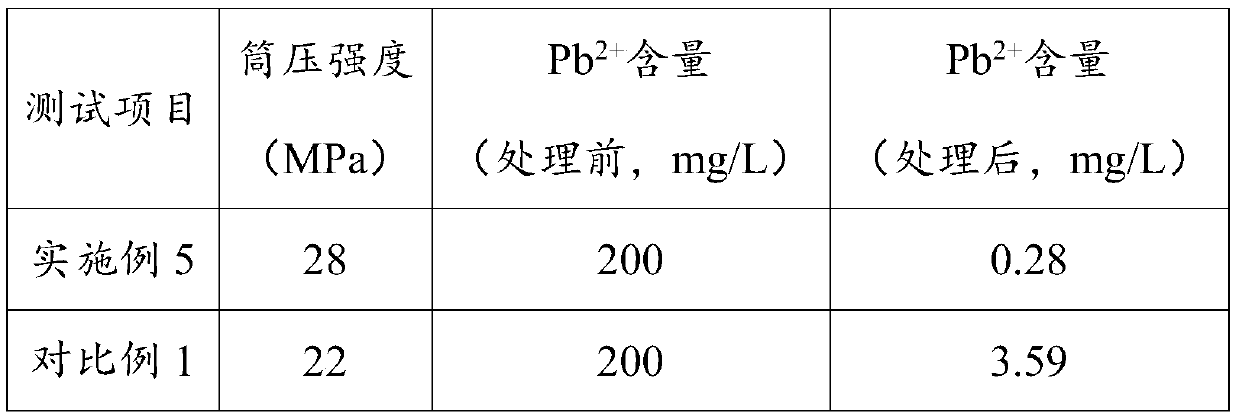

Examples

Embodiment 1

[0021] This embodiment provides a kind of biomass sludge ceramsite, and its preparation method comprises the following steps:

[0022] (1) Weigh 60g of biomass co-burning ash, 30g of sludge powder, and 15g of fly ash, and set aside. Among them, the preparation method of biomass co-firing ash is as follows: after mixing 25g of rice husk powder, 20g of sawdust powder, and 60g of sludge powder, they are placed in a muffle furnace at 700°C for calcination for 3 hours, and then cooled to room temperature, the biomass co-burning ash can be obtained.

[0023] (2) Mix biomass co-burning ash, sludge powder and fly ash, and then process them into granules no smaller than 1 cm in diameter to obtain granular materials.

[0024] (3) Put the granular material in an oven at 100°C for 10 minutes, then place it in a muffle furnace at 500°C for 10 minutes, and then heat it up to 1000°C at a rate of 20°C / min for calcination Treat for 10 minutes and cool down to room temperature naturally to ge...

Embodiment 2

[0026] This embodiment provides a kind of biomass sludge ceramsite, and its preparation method comprises the following steps:

[0027] (1) Weigh 80g of biomass co-burning ash, 10g of sludge powder, and 5g of fly ash, and set aside. Among them, the preparation method of biomass co-firing ash is as follows: after mixing 45g of rice husk powder, 10g of sawdust powder, and 40g of sludge powder, they are then calcined in a muffle furnace at 900°C for 3 hours, and then cooled to room temperature, the biomass co-burning ash can be obtained.

[0028] (2) Mix biomass co-burning ash, sludge powder and fly ash, and then process them into granules no smaller than 1 cm in diameter to obtain granular materials.

[0029] (3) Put the granular material in an oven at 110°C for 20 minutes, then place it in a muffle furnace at 600°C for 20 minutes, and then heat it up to 1200°C at a rate of 50°C / min for calcination Treat for 20 minutes and cool down to room temperature naturally to get biomass ...

Embodiment 3

[0031] This embodiment provides a kind of biomass sludge ceramsite, and its preparation method comprises the following steps:

[0032] (1) Weigh 65g of biomass co-burning ash, 25g of sludge powder, and 12g of fly ash, and set aside. Among them, the preparation method of biomass co-firing ash is as follows: after mixing 30g of rice husk powder, 16g of sawdust powder, and 55g of sludge powder, they are placed in a muffle furnace at 800°C for calcination for 3 hours, and then cooled to room temperature, the biomass co-burning ash can be obtained.

[0033] (2) Mix biomass co-burning ash, sludge powder and fly ash, and then process them into granules no smaller than 1 cm in diameter to obtain granular materials.

[0034] (3) Put the granular material in an oven at 105°C for 15 minutes, then place it in a muffle furnace at 550°C for 15 minutes, and then heat it up to 1100°C at a rate of 30°C / min for calcination Treat for 15 minutes, and naturally cool to room temperature to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com