Low-indium doping amount zinc oxide transparent conducting film and preparation method thereof

A technology of transparent conductive film and zinc oxide, which is applied to conductive materials, conductive materials, conductive layers on insulating carriers, etc., can solve the problems of high cost and high indium content, and achieve reduced indium content, low indium content, and good electrical conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

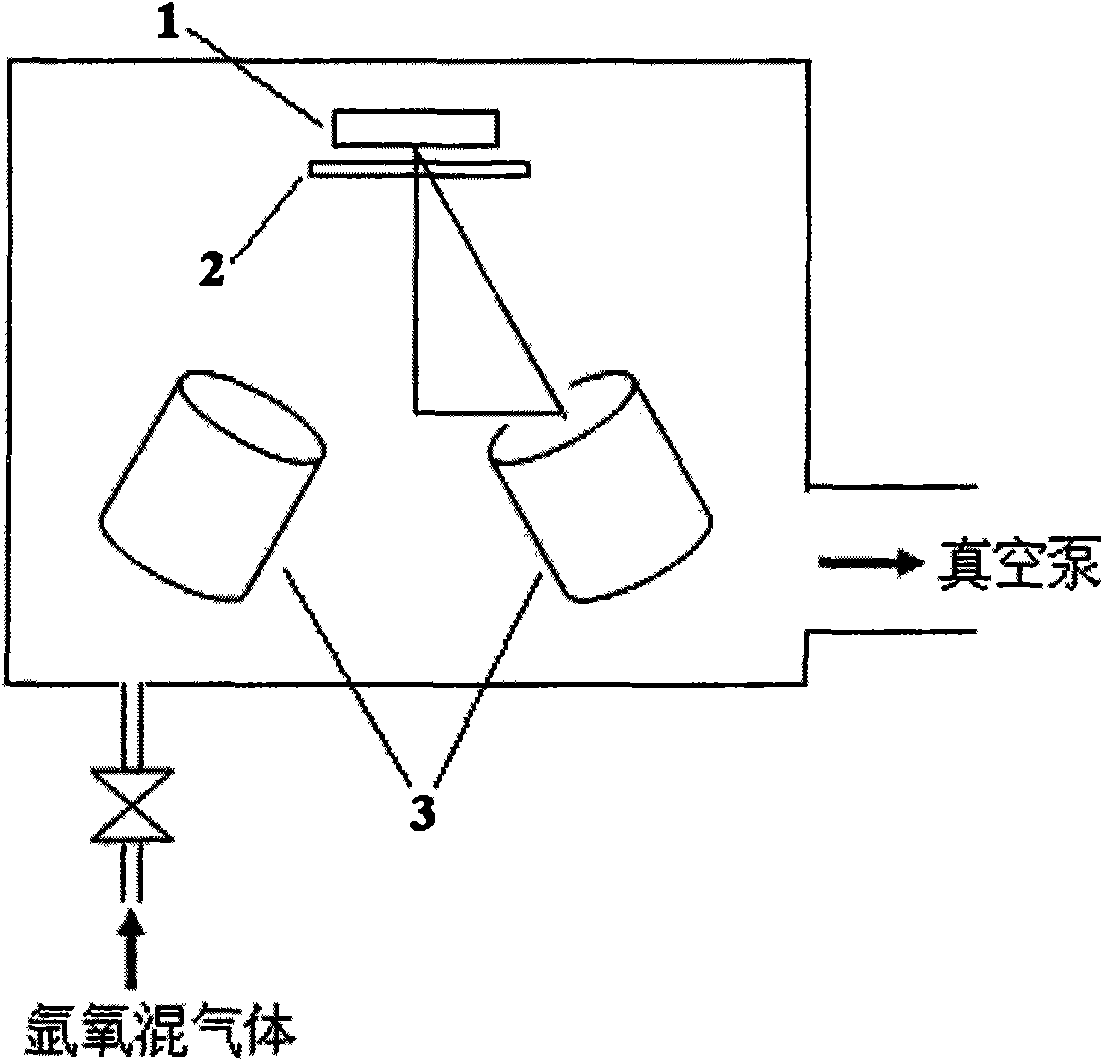

[0015] Example 1: A low-indium-doped zinc oxide transparent conductive film was prepared by multi-target co-sputtering magnetron sputtering.

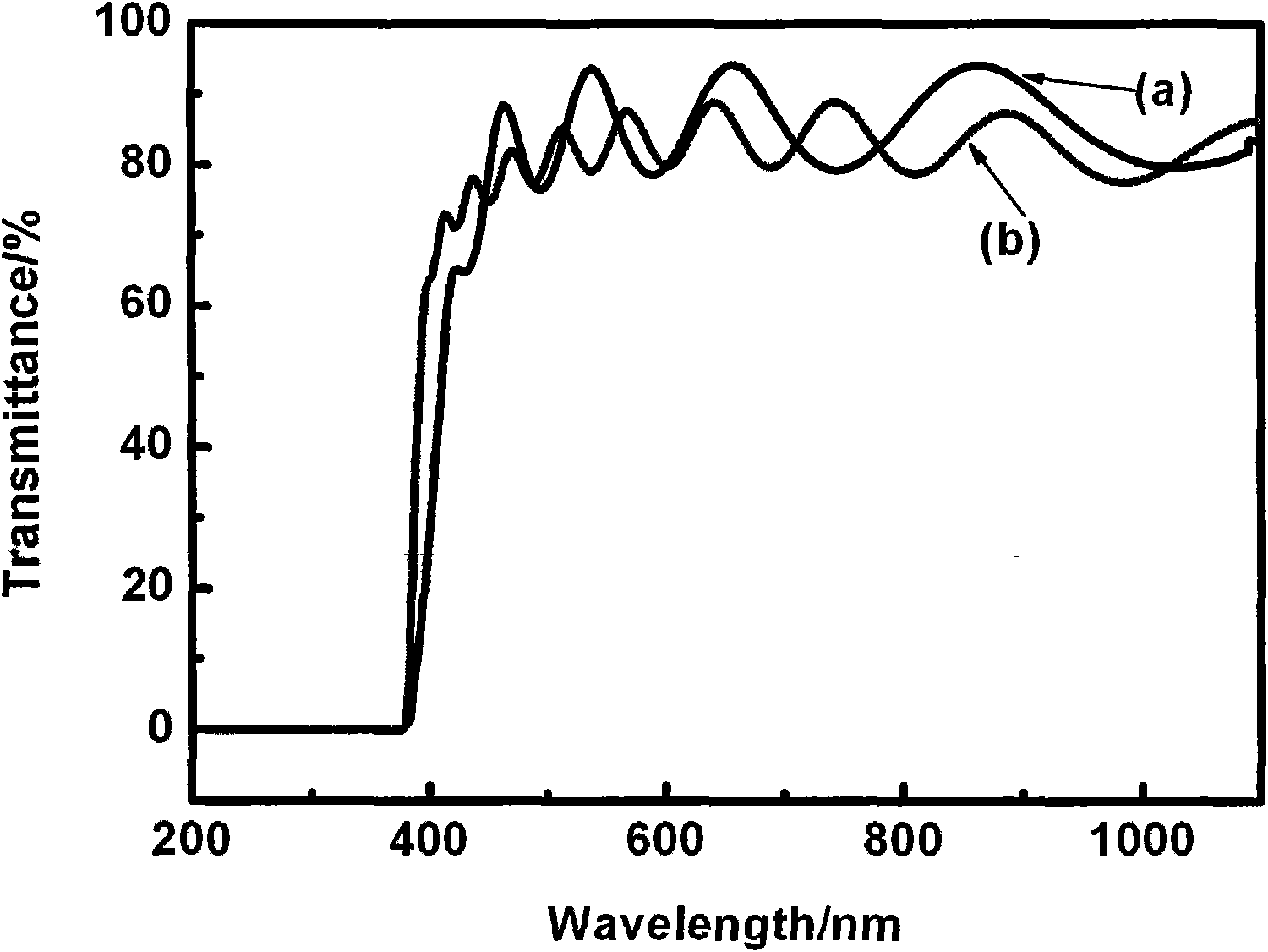

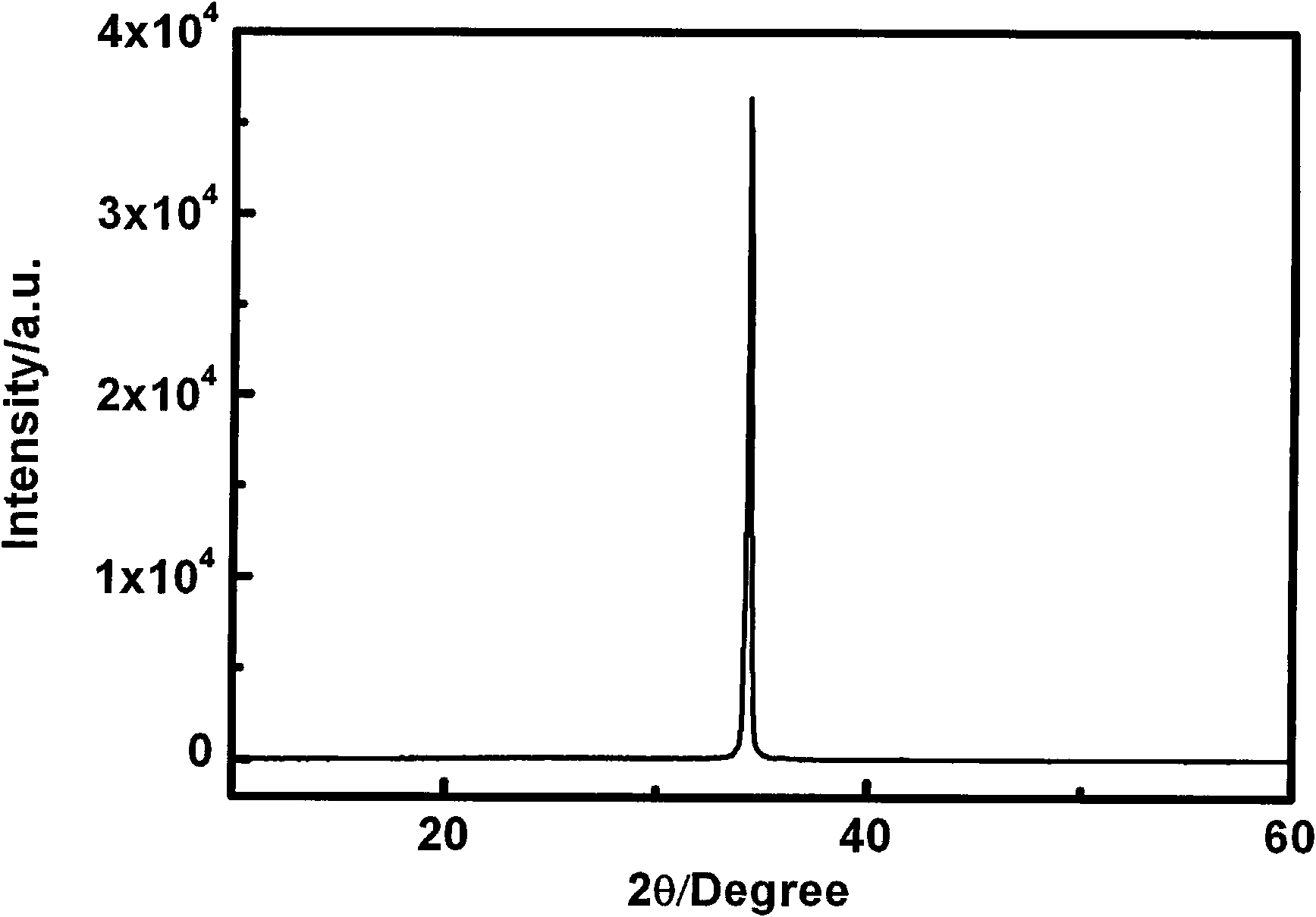

[0016] The purity of the zinc oxide ceramic target for sputtering is 99.9%, the purity of the indium metal target is 99.9%, and the relative density is ~0.90. Install the targets in two opposing target guns (such as figure 1 shown), adjust the angle between the target gun and the vertical direction to ~30°, and evacuate until the background vacuum degree of the vacuum chamber is higher than 2.0×10 -4 Pa. Use quartz glass as the substrate, keep the substrate temperature at 400°C, feed 40sccm argon and 2sccm oxygen into the vacuum chamber (sccm means standard milliliters per minute), adjust the pressure of the vacuum chamber to 0.5Pa, and the RF power supply corresponding to the zinc oxide target The power is adjusted to 150W, the power of the RF power supply corresponding to the indium target is adjusted to 15W, the bias voltage is adj...

Embodiment 2

[0018] The purity of the zinc oxide ceramic target for sputtering is 99.9%, the purity of the indium metal target is 99.9%, and the relative density is ~0.90. Install the targets in two opposing target guns (such as figure 1 shown), adjust the angle between the target gun and the vertical direction to be ~30°, and evacuate until the background vacuum degree of the vacuum chamber is higher than 2.0×10 -4 Pa. With ordinary alkali glass as the substrate, the substrate temperature is kept at 400°C, 40sccm argon gas (sccm means standard milliliter per minute) is introduced into the vacuum chamber, the pressure of the vacuum chamber is adjusted to 0.5Pa, and the RF power supply corresponding to the zinc oxide target is adjusted. The power of the RF power supply corresponding to the indium target is adjusted to 25W, the bias voltage is adjusted to -50V, and the sample rotation rate is 6 rpm. Under these conditions, the film growth rate is ~22nm / min. Before the formal deposition of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com