Multi-walled composite conductive carbon nanotube-polyvinylidene fluoride ultrafiltration membrane and preparation method thereof

A kind of technology of multi-wall carbon nanotube and polyvinylidene fluoride

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

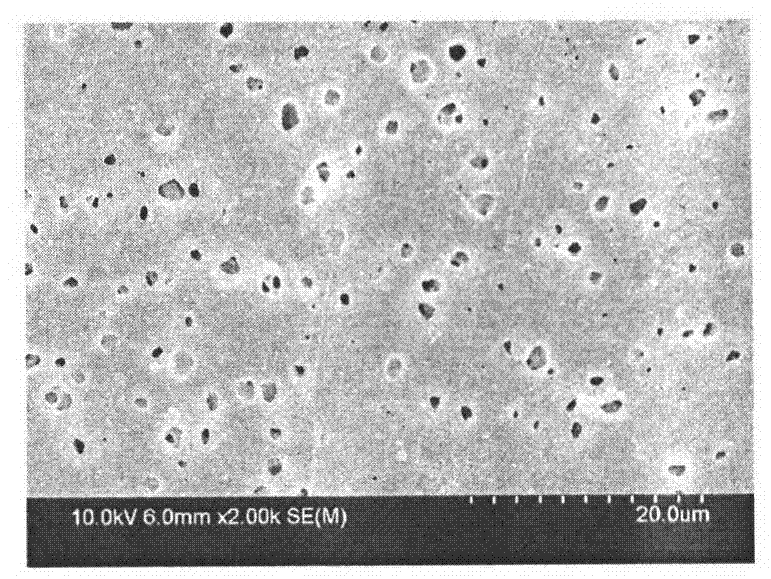

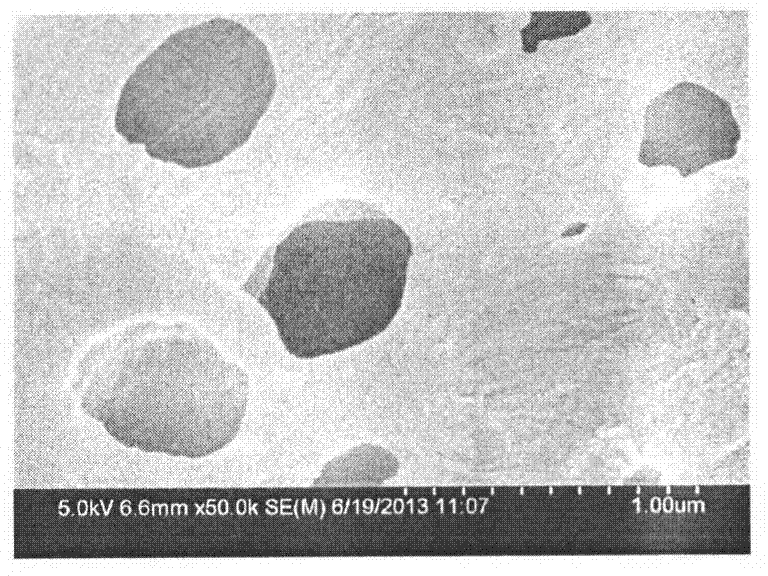

Embodiment 1

[0029] Add 0.18g of carboxylated multi-walled carbon nanotubes (with an aspect ratio of 500-3000:1) to 42g of N-N dimethylacetamide and disperse ultrasonically for 1 hour through an ultrasonic cleaner, then put them into a cell pulverizer for ultrasonic dispersion Half an hour, then add 6g of polyvinylidene fluoride, stir magnetically in a constant temperature water bath at 60°C for 5 hours, then ultrasonically disperse for 2 hours with an ultrasonic cleaner, then put it into a cell pulverizer for ultrasonic dispersion for 1 hour, and finally place it at 35°C After standing in a vacuum drying oven for 2 hours for degassing, scrape a film with a uniform thickness on a glass plate at room temperature. After repeated washing with water, soak in new deionized water for 48 hours, soak the membrane in absolute ethanol for 48 hours, take it out, rinse it with deionized water repeatedly, and finally dry the cleaned membrane in a vacuum at 40 °C After oven drying, the film performance ...

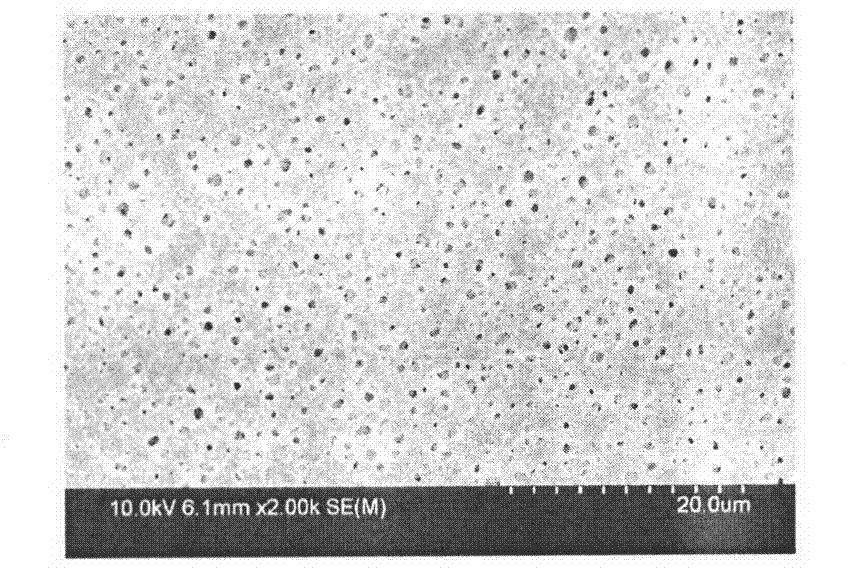

Embodiment 2

[0031] Add 0.35g of carboxylated multi-walled carbon nanotubes (with an aspect ratio of 500-3000:1) into 40g of N-N dimethylacetamide and disperse ultrasonically for 1 hour with an ultrasonic cleaner, then put them into a cell pulverizer for ultrasonic dispersion Half an hour, then add 7g of polyvinylidene fluoride, stir magnetically in a constant temperature water bath at 60°C for 5 hours, then ultrasonically disperse for 2 hours with an ultrasonic cleaner, then put it into a cell pulverizer for ultrasonic dispersion for 1 hour, and finally place it at 35°C After standing in a vacuum drying oven for 2 hours for degassing, scrape a film with a uniform thickness on a glass plate at room temperature. After repeated washing with water, soak in new deionized water for 48 hours, soak the membrane in absolute ethanol for 48 hours, take it out, rinse it with deionized water repeatedly, and finally dry the cleaned membrane in a vacuum at 40 °C After oven drying, the film performance c...

Embodiment 3

[0033] Add 0.5g (length-diameter ratio: 500-3000:1) carboxylated multi-walled carbon nanotubes to 60g N-N dimethylacetamide, ultrasonically disperse for 1 hour through an ultrasonic cleaner, and then put into a cell pulverizer for ultrasonic dispersion After half an hour, add 5g of polyvinylidene fluoride, stir magnetically in a constant temperature water bath at 60°C for 5 hours, then ultrasonically disperse for 2 hours with an ultrasonic cleaner, then put it into a cell pulverizer for ultrasonic dispersion for 1 hour, and finally place it at 35°C After standing in a vacuum drying oven for 2 hours for degassing, scrape a film with a uniform thickness on a glass plate at room temperature. After repeated washing with water, soak in new deionized water for 48 hours, soak the membrane in absolute ethanol for 48 hours, take it out, rinse it with deionized water repeatedly, and finally dry the cleaned membrane in a vacuum at 40 °C After oven drying, the film performance can be test...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com