Method for preparing graphene film

A graphene film and film technology, applied in the field of graphene, can solve problems such as environmental pollution, graphene is not easy to form a film, and process conditions are difficult to control, so as to achieve the effect of simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The preparation method of the graphene film preparation method of the present invention is introduced below in conjunction with specific examples.

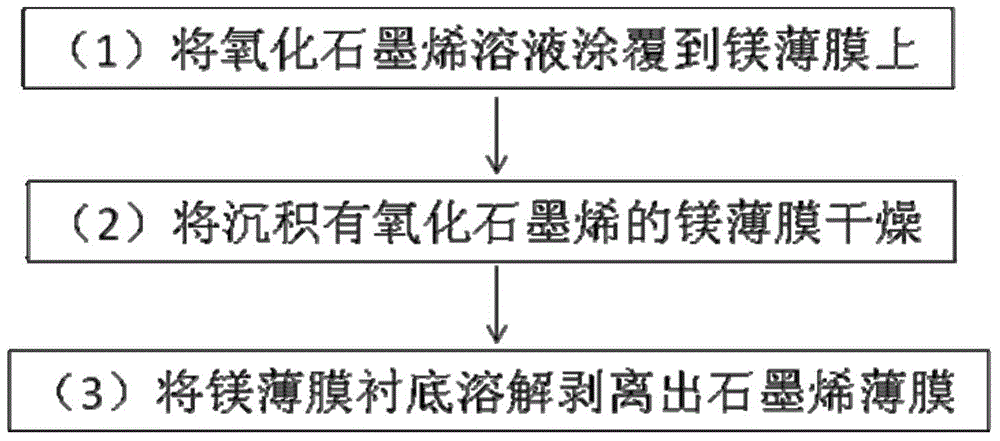

[0031] The processing steps of the preparation method for preparing graphene film provided by the embodiment of the present invention are as follows: figure 1 shown, including but not limited to the following steps:

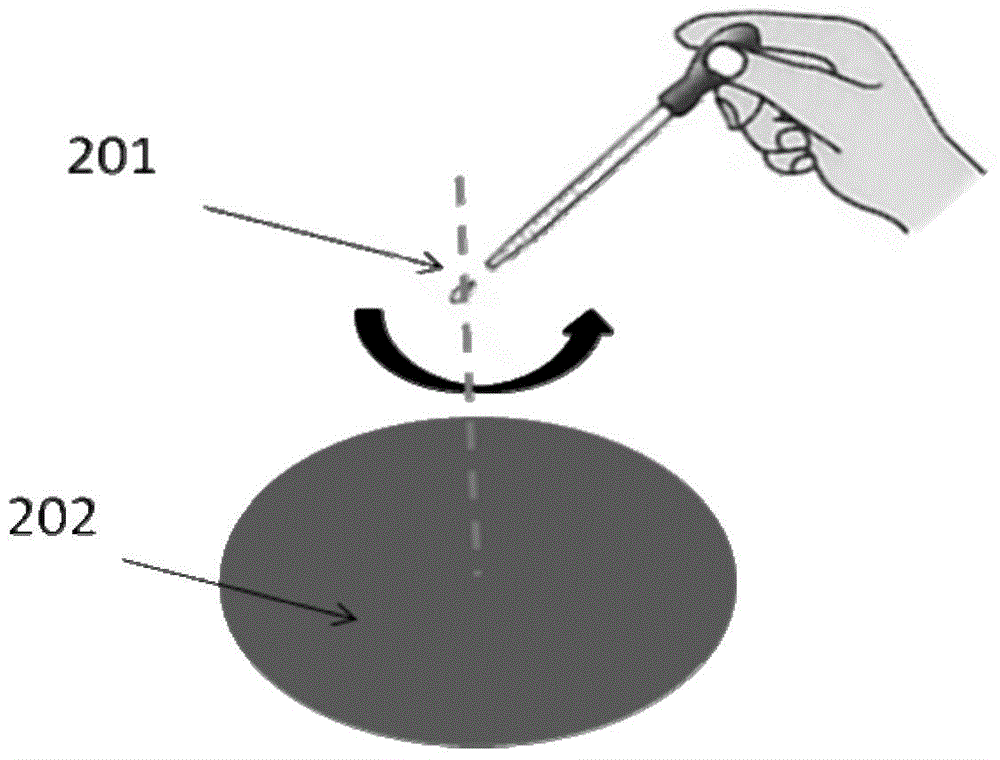

[0032] (1) graphene oxide acidic solution is coated on the magnesium film;

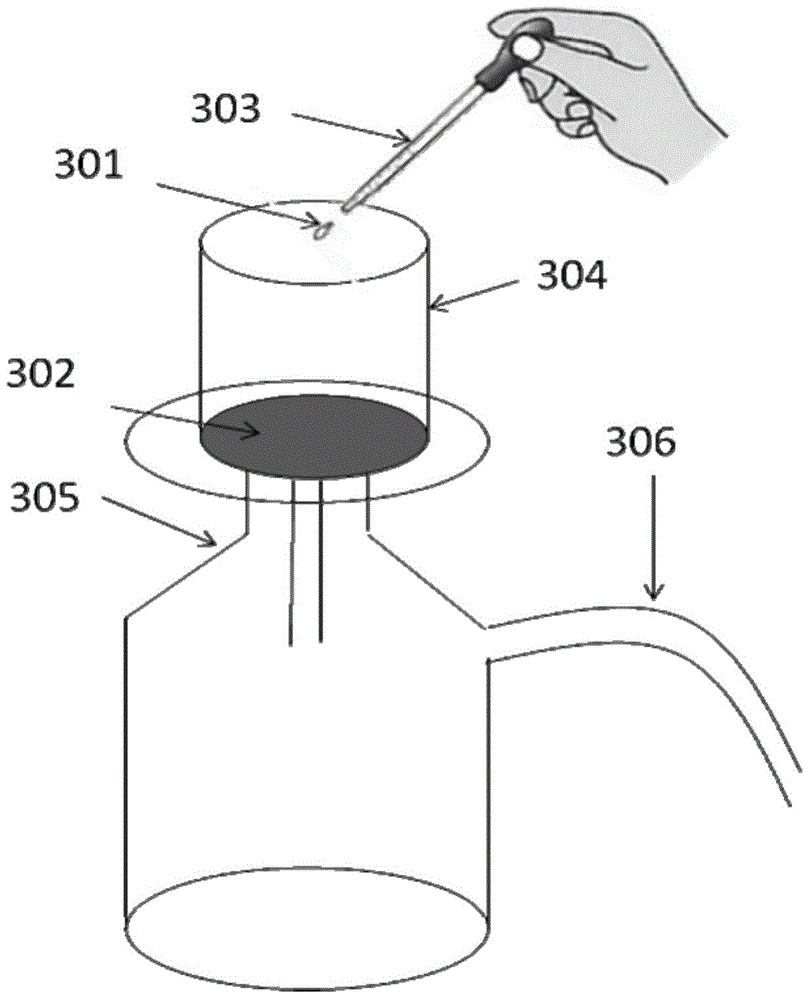

[0033] (2) drying the magnesium film deposited with graphite oxide;

[0034] (3) The graphene film is peeled off from the magnesium film.

[0035] Due to the method of preparing graphene using hydrazine hydrate as a reducing agent, the reducibility of hydrazine hydrate is too strong to cause a violent reaction and affect the quality of the graphene film. At the same time, the strong toxicity of hydrazine hydrate pollutes the environment. After a complicated waste gas treatment process, the method of vacuum thermal expansion require...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com