High-performance natural graphite-MnO composite electrode material and preparation method thereof

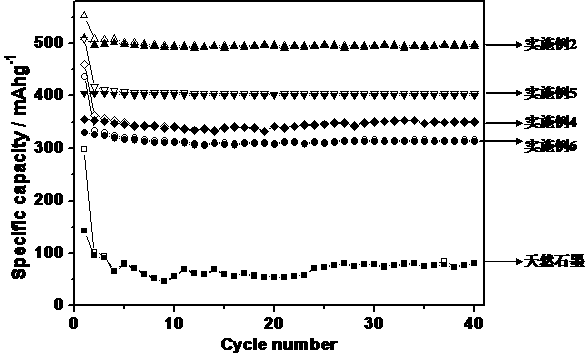

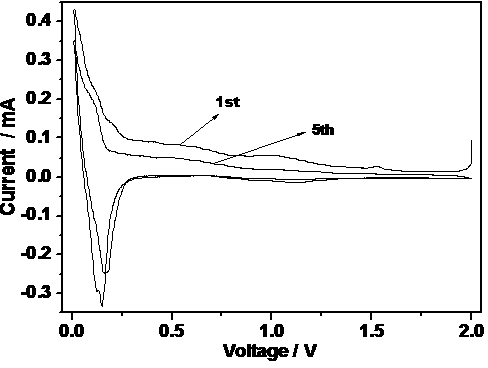

A natural graphite and electrode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of poor structural stability and low tap density, and achieve stable structure, high tap density, and good reversibility of charge and discharge reactions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

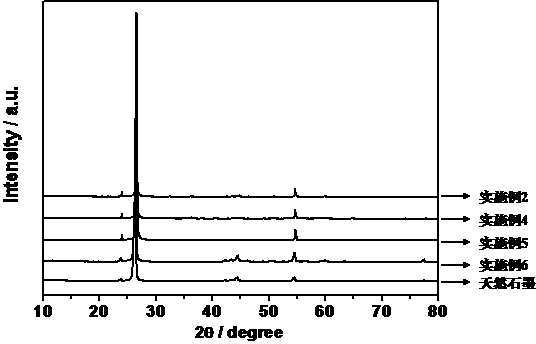

Examples

Embodiment 1

[0028] A preparation method of natural graphite and MnO composite negative electrode material:

[0029] Spheroidize natural flake graphite to average particle size D 50 = 17 μm, adding natural flake graphite to KMnO 4 In the aqueous solution (5g / L), stir into a uniform dispersion, natural flake graphite and KMnO 4 The mass percentage of 85wt%: 15wt%. Add the dispersion liquid into a stainless steel reaction kettle and seal it, heat it to 160°C, keep it warm for 10 hours, cool it to room temperature, filter it with suction, and wash it with deionized water until it is colorless. The obtained product was vacuum-dried at 50°C for 5 hours (vacuum degree -0.1MPa), and then heat-treated at 500°C for 10 hours under an argon atmosphere to obtain a composite material of natural graphite and MnO. The obtained composite material was milled in a ball mill for 4 hours, the frequency of the ball mill was 45 Hz, and after passing through a 200-mesh sieve, the composite high-performance e...

Embodiment 2

[0031] Spheroidize natural flake graphite to average particle size D 50 = 17 μm, adding natural flake graphite to KMnO 4 In the aqueous solution (5g / L), stir into a uniform dispersion, natural flake graphite and KMnO 4 The mass percentage of 85wt%: 15wt%. Add the dispersion liquid into a stainless steel reaction kettle and seal it, heat it to 160°C, keep it warm for 10 hours, cool it to room temperature, filter it with suction, and wash it with deionized water until it is colorless. The obtained product was vacuum-dried at 50°C for 5 hours (vacuum degree -0.1MPa), and then heat-treated at 600°C for 10 hours under an argon atmosphere to obtain a composite material of natural graphite and MnO. The obtained composite material was milled in a ball mill for 4 hours, the frequency of the ball mill was 45 Hz, and after passing through a 200-mesh sieve, the composite high-performance electrode material of natural graphite and MnO was obtained.

Embodiment 3

[0033] Spheroidize natural flake graphite to average particle size D 50 = 17 μm, adding natural flake graphite to KMnO 4 In the aqueous solution (5g / L), stir into a uniform dispersion, natural flake graphite and KMnO 4 The mass percentage of 85wt%: 15wt%. Add the dispersion liquid into a stainless steel reaction kettle and seal it, heat it to 160°C, keep it warm for 10 hours, cool it to room temperature, filter it with suction, and wash it with deionized water until it is colorless. The obtained product was vacuum-dried at 50°C for 5 hours (vacuum degree -0.1MPa), and then heat-treated at 700°C for 10 hours under an argon atmosphere to obtain a natural graphite and MnO composite material. The obtained composite material was milled in a ball mill for 4 hours, the frequency of the ball mill was 45 Hz, and after passing through a 200-mesh sieve, the composite high-performance electrode material of natural graphite and MnO was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com