Geopolymer adsorption material and preparation method thereof

A technology of geopolymers and adsorption materials, applied in the fields of silicon compounds, chemical instruments and methods, adsorbed water/sewage treatment, etc. Low cost, high cost, good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The preparation of embodiment 1 geopolymer adsorption material

[0038] The present embodiment provides a geopolymer adsorption material, including the following raw materials in parts by weight: 33.3 parts of fly ash, 66.7 parts of metakaolin, 65.6 parts of water glass, 14.4 parts of sodium hydroxide and 40 parts of deionized water;

[0039] Among them, metakaolin is obtained by calcining raw kaolin powder at 900°C for 3 hours, and the fly ash and metakaolin are respectively passed through a 100-mesh sieve; the modulus of water glass is 3.3.

[0040] The preparation method of the geopolymer adsorption material of the present embodiment comprises the following steps:

[0041] (1) Mix fly ash and metakaolin evenly to obtain aluminosilicate powder;

[0042] (2) After mixing water glass and sodium hydroxide, carry out ultrasonic treatment for 20 minutes, and then stand at room temperature for 24 hours to obtain an alkali activator;

[0043] (3) mix the aluminosilicate po...

Embodiment 2

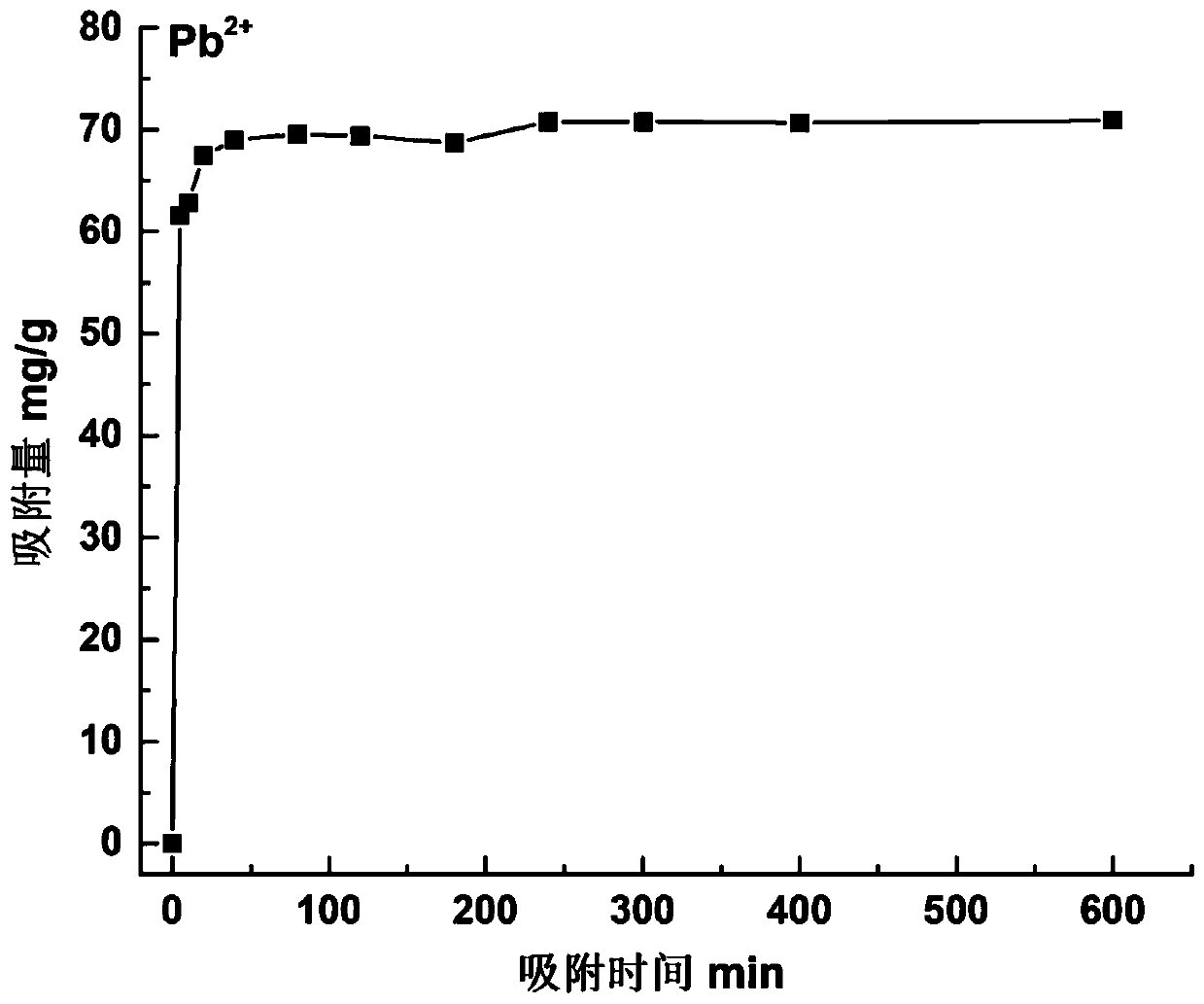

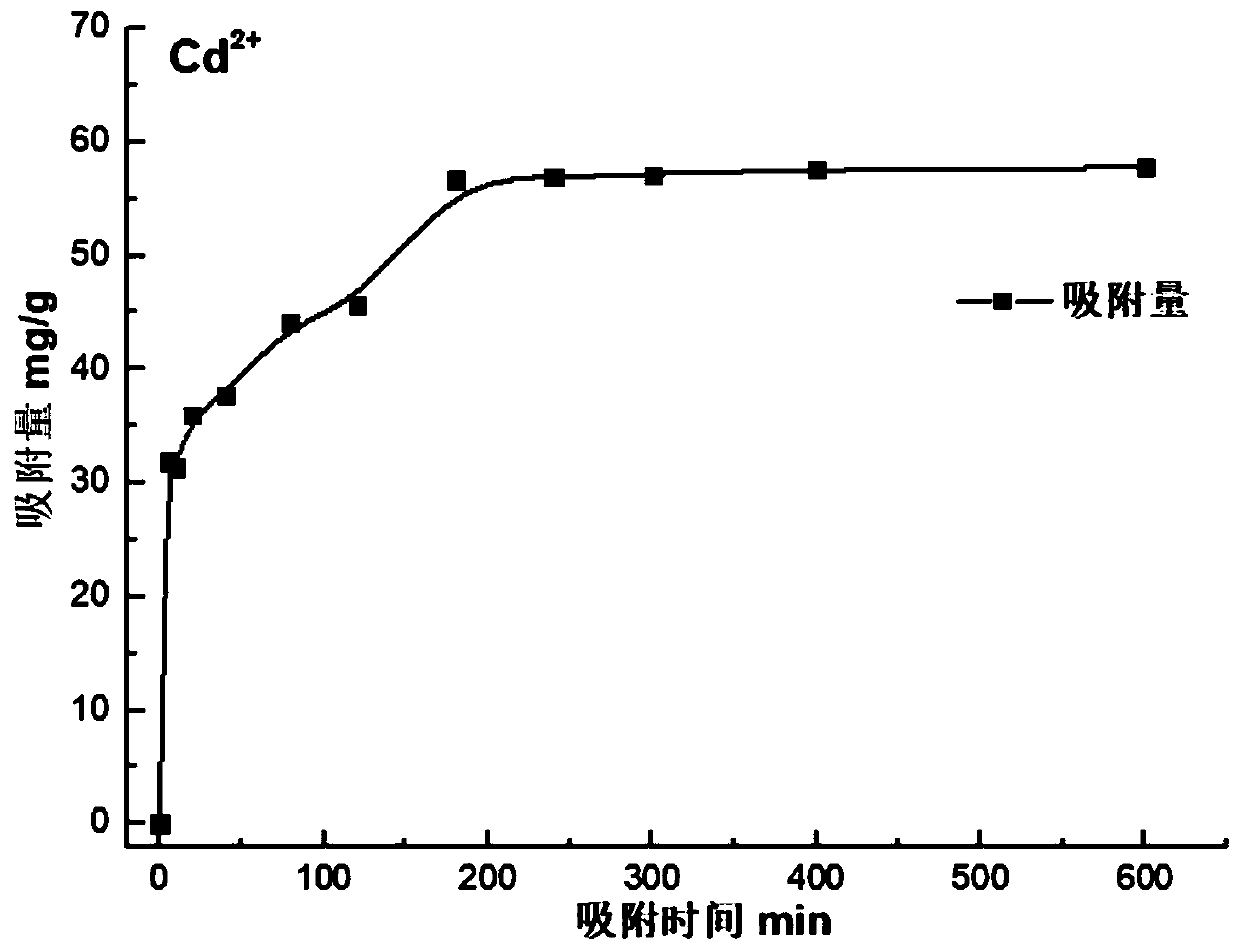

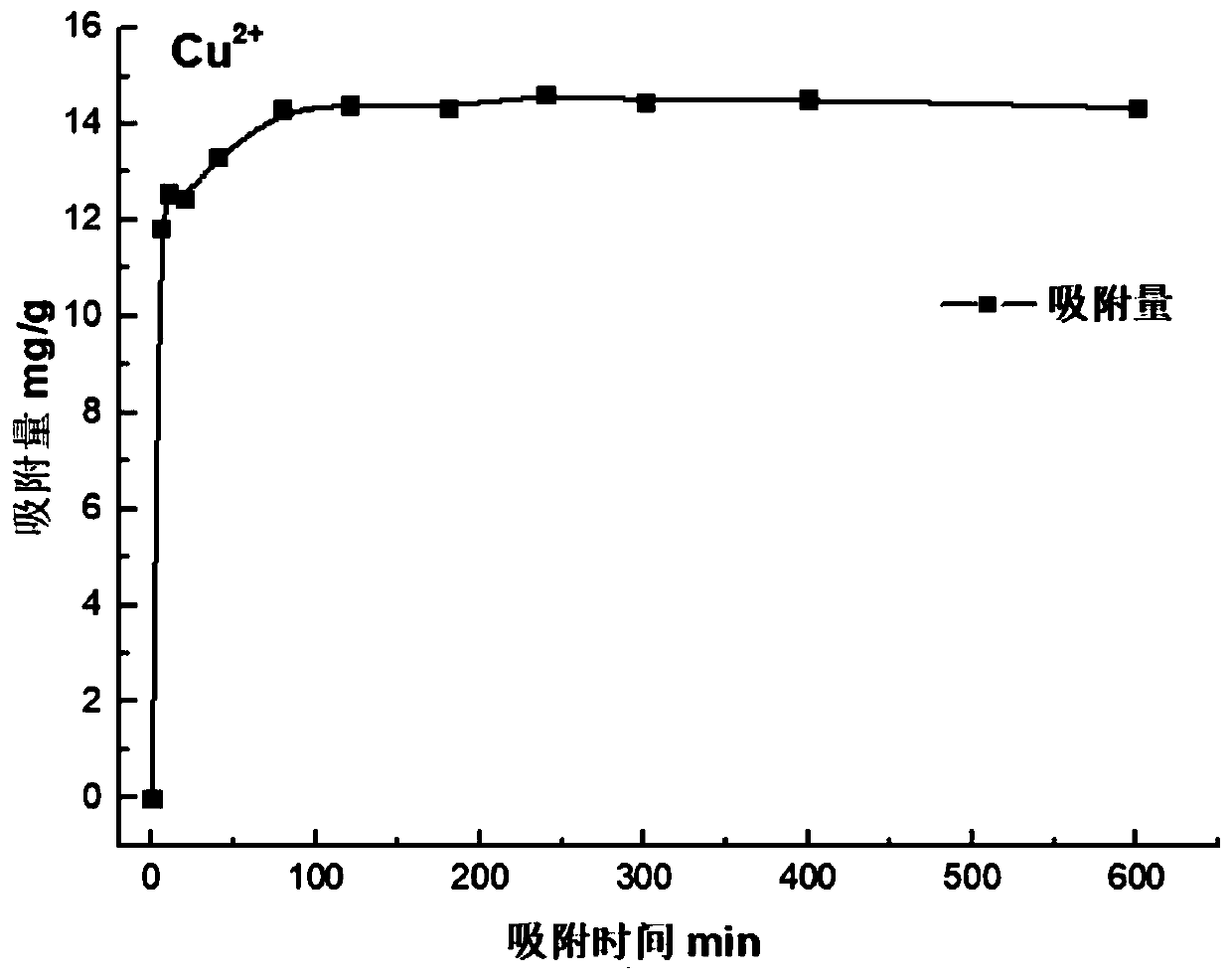

[0047] Embodiment 2 Utilizes the geopolymer adsorption material of Embodiment 1 to adsorb heavy metal ions in the solution under different time conditions

[0048] Using Pb(NO 3 ) 2 , Cd(NO 3 ) 2 and Cu(NO 3 ) 2 Reagents prepare a certain concentration of heavy metal solutions, using NaOH and HNO 3 Adjust the pH of the solution. Weigh 0.1 g of geopolymer adsorption material, add it to 25 ml of heavy metal solution, shake at 25°C, and absorb heavy metals under different time conditions. The adsorption solution was filtered through a microporous membrane with a pore size of 0.45 μm, and the concentration of heavy metal ions in the solution was determined by atomic absorption method.

[0049] Among them, the initial concentration and initial pH of heavy metal ions in each solution are: Pb 2+ 300mg / L, pH=3; Cd 2+ 300mg / L, pH=5; Cu 2+ 200mg / L, pH=4. The adsorption time gradient is set as: 0, 5, 10, 20, 40, 80, 120, 180, 240, 300, 400, 600min.

[0050] Effect of geopolym...

Embodiment 3

[0051] Embodiment 3 Utilizes the geopolymer adsorption material of Embodiment 1 to adsorb heavy metals of different concentrations

[0052] Using Pb(NO 3 ) 2 , Cd(NO 3 ) 2 , Cu(NO 3 ) 2 The reagents prepare heavy metal solutions with different concentration gradients, using NaOH and HNO 3 Adjust the pH of the solution. Pb 2+ The initial pH is set to 3, and the initial concentration gradient is set to 100, 200, 300, 500, 800, 1000mg / L; Cd 2+ The initial pH is set to 5, and the initial concentration gradient is set to 50, 100, 200, 300, 500, 800mg / L; Cu 2+ The initial pH was set to 4, and the initial concentration gradient was set to 50, 100, 200, 300, 500mg / L.

[0053] Weigh 0.1 g of geopolymer adsorption material, add it to 25 ml of heavy metal solution, and shake for 300 min at 25 ° C to make the adsorption reach equilibrium. The adsorption solution was filtered through a microporous membrane with a pore size of 0.45 μm, and the concentration of heavy metal ions in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com