Method for preparing hydroxyapatite bioactive coating

A technology of hydroxyapatite and biological activity, applied in the direction of coating, etc., can solve the problem of poor bonding strength between carbon nanotubes and matrix materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

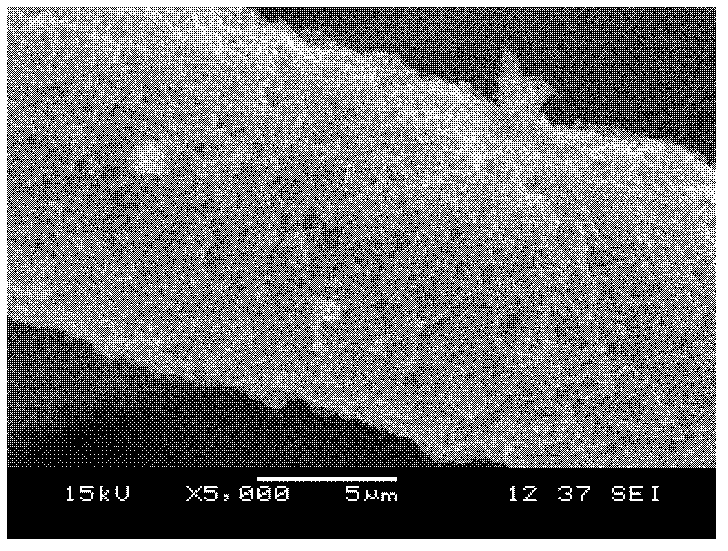

Image

Examples

Embodiment 1

[0020] (1) The carbon fiber prefabricated body is ultrasonically cleaned with acetone, absolute ethanol and distilled water in sequence, and then placed in a vacuum drying oven to dry to obtain sample A;

[0021] (2) Sample A was placed in nitric acid (50% by volume), soaked at 50°C for 10 hours, then ultrasonically cleaned with distilled water and then dried in a vacuum oven to obtain sample B;

[0022] (3) Nickel nitrate and acetone were mixed according to the mass ratio of 1%, and ultrasonically oscillated for 30 minutes to form a uniform solution;

[0023] (4) Place sample B in the solution prepared in step (3), soak for 12 hours at 25 degrees, and then put it into a vacuum drying oven to dry to obtain sample C;

[0024] (5) Place sample C in a chemical vapor deposition furnace, calcinate at 400°C for 30 minutes, then feed in hydrogen with a flow rate of 80L / h for reduction reaction, and the reduction time is 20 minutes; then heat up to 720°C, and feed in propylene (Flow ...

Embodiment 2

[0029] (1) The carbon / carbon composite material was ultrasonically cleaned with acetone, absolute ethanol and distilled water in sequence, and then put into a vacuum drying oven to dry to obtain sample A;

[0030] (2) Sample A was placed in nitric acid (60% by volume), soaked at 60°C for 12 hours, then ultrasonically cleaned with distilled water and then dried in a vacuum oven to obtain sample B;

[0031] (3) Nickel nitrate and acetone were mixed according to a mass ratio of 3%, and ultrasonically oscillated for 60 minutes to form a uniform solution;

[0032] (4) Place sample B in the solution prepared in step (3), soak for 15 hours at 30 degrees, and then put it into a vacuum drying oven to dry to obtain sample C;

[0033] (5) Place sample C in a chemical vapor deposition furnace, calcinate at 450°C for 50 minutes, then feed in hydrogen with a flow rate of 100L / h for reduction reaction, the reduction time is 30 minutes; then heat up to 750°C, and feed in propylene (Flow rate...

Embodiment 3

[0037] (1) The carbon fiber prefabricated body is ultrasonically cleaned with acetone, absolute ethanol and distilled water in sequence, and then placed in a vacuum drying oven to dry to obtain sample A;

[0038] (2) Sample A was placed in nitric acid (55% by volume), soaked at 55°C for 11 hours, then ultrasonically cleaned with distilled water and then dried in a vacuum oven to obtain sample B;

[0039] (3) Nickel nitrate and acetone were mixed according to the mass ratio of 2%, and ultrasonically oscillated for 45 minutes to form a uniform solution;

[0040](4) Place sample B in the solution prepared in step (3), soak for 14 hours at 28 degrees, and then put it into a vacuum drying oven to dry to obtain sample C;

[0041] (5) Place sample C in a chemical vapor deposition furnace, calcinate at 420°C for 40 minutes, then feed in hydrogen with a flow rate of 90L / h for reduction reaction, the reduction time is 25 minutes; then heat up to 730°C, and feed in propylene (Flow rate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com