Method for polylactic acid high polymer material surface modified hydroxyapatite coating

A polymer material and hydroxyapatite technology, which is applied in the field of hydroxyapatite coating on the surface of polylactic acid-based polymer materials, can solve the problems of general quality of polylactic acid-based polymer materials, long coating preparation period, and coating Non-uniformity and other problems, to achieve the effect of improving osteoinductivity, shortening the preparation cycle, and being environmentally friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] 1. Take poly-L-lactic acid with a molecular weight of 10,000 and wash it with water and ethanol in order;

[0016] 2. Soak the material in 0.01mol / L dopamine aqueous solution (use tri-HCl buffer to adjust PH=8) after activation, and then wash with water once to remove physically adsorbed organic matter;

[0017] 3. Soak the activated material in 0.01mol / L calcium nitrate aqueous solution, take it out and wash it with water once to remove unadsorbed Ca 2+ ion;

[0018] 4. Then, soak in 0.006mol / L diammonium hydrogen phosphate aqueous solution (adjust PH=8 with ammonia water), take it out and wash it with primary water to remove unadsorbed PO 4 3- ion, to dry;

[0019] 5. According to steps 3 and 4, soak 3 times in a cycle to obtain a layer of uniform and dense hydroxyapatite coating.

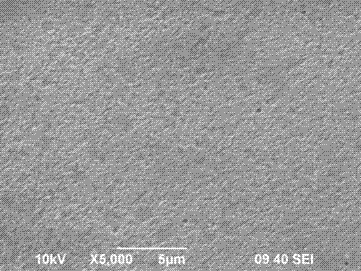

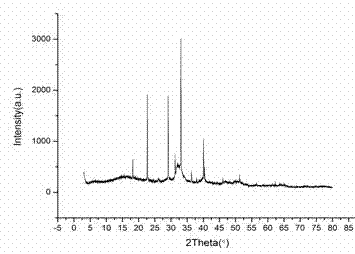

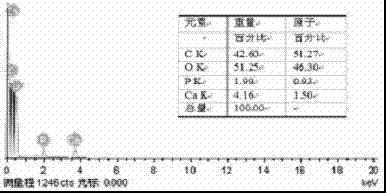

[0020] The scanning electron microscope pictures of the resulting hydroxyapatite coatings are shown in figure 1 , X-ray diffraction pattern see figure 2 , EDS energy spectrum see ...

Embodiment 2

[0022] 1. Take poly D,L-lactic acid with a molecular weight of 100,000 and wash it with water and ethanol in order;

[0023] 2. Soak the material in 0.5mol / L 2-hydroxyethylamine aqueous solution to activate it, then wash it with water once to remove the physically adsorbed organic matter;

[0024] 3. Soak the activated material in 0.5mol / L calcium chloride aqueous solution, take it out and wash it with water once to remove unadsorbed Ca 2+ ion;

[0025] 4. Then, soak in 0.3mol / L ammonium dihydrogen phosphate aqueous solution (adjust pH=10 with ammonia water), take it out and wash it with water once to remove unadsorbed PO 4 3- ion, to dry;

[0026] 5. According to steps 3 and 4, cycle soaking 20 times to obtain a layer of uniform and dense hydroxyapatite coating.

Embodiment 3

[0028] 1. Take the poly-L-lactic acid-glycolic acid copolymer with a molecular weight of 200,000 and wash it with water and ethanol in order;

[0029] 2. Soak the material in a 1mol / L β-alanine aqueous solution to activate it, then wash it with water once to remove the physically adsorbed organic matter;

[0030] 3. Soak the activated material in 1mol / L calcium hydroxide aqueous solution, take it out and wash it with water once to remove unadsorbed Ca 2+ ion;

[0031] 4. Then, soak in 0.6mol / L disodium hydrogen phosphate aqueous solution (adjust PH=12 with ammonia water), take it out and wash it with primary water to remove unadsorbed PO 4 3- ion, to dry;

[0032] 5. According to steps 3 and 4, soak 50 times in a cycle to obtain a layer of uniform and dense hydroxyapatite coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com