Method of preparing electrophoretic deposited hydroxyl apatite coating on Ti or Ti alloy surface

A hydroxyapatite, electrophoretic deposition technology, applied in coatings, electrolytic coatings, electrophoretic plating, etc., can solve the problems of limited application, low bonding strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

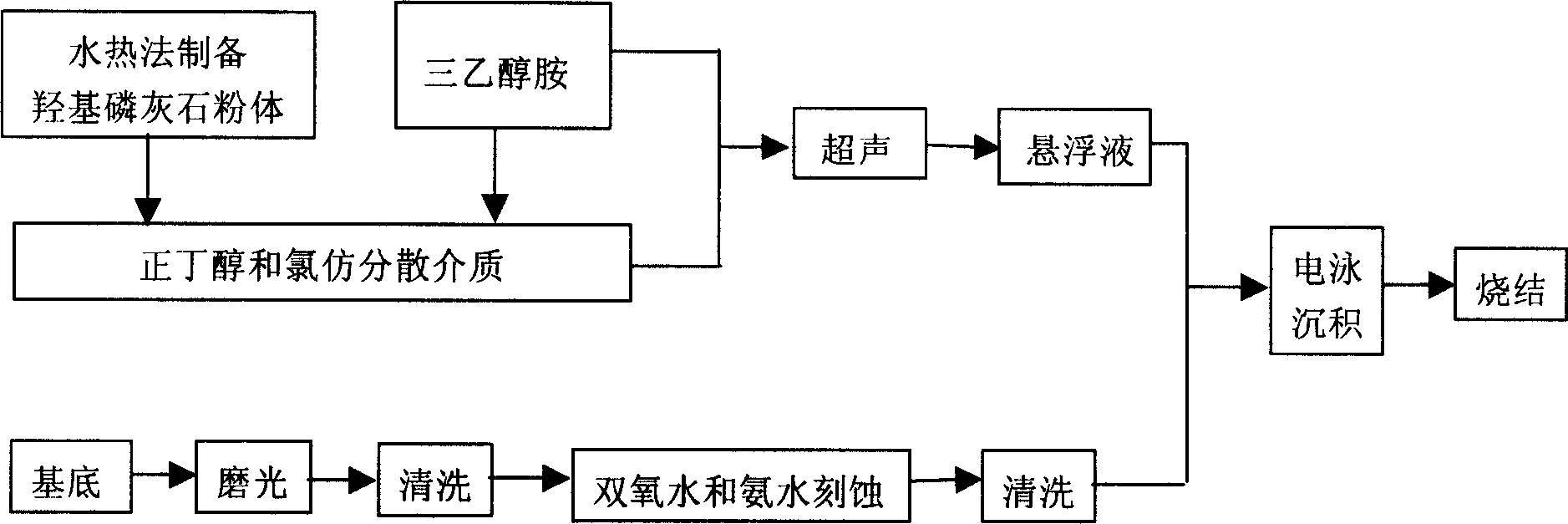

Method used

Image

Examples

Embodiment 1

[0020] Preparation of hydroxyapatite powder: add 0.2g (concentration: 8g / L) polyethylene glycol to 25mL 0.5mol / L calcium nitrate solution, stir to dissolve and adjust the pH of the solution to ≥ 11.00 with ammonia water, drop by drop under magnetic stirring Add 25mL, 0.3mol / L, ammonium phosphate solution with pH ≥ 10, and finish adding in about 10 minutes. After standing still, the precipitate and the solution were transferred into a stainless steel autoclave lined with polytetrafluoroethylene, and the autoclave was placed in a constant temperature drying oven for hydrothermal reaction at 200°C for 8 hours. After natural cooling, wash with distilled water twice, then with absolute ethanol, filter with suction, and finally dry at 100°C for 1 hour, weigh about 1.1g of hydroxyapatite powder, and store it in a weighing bottle .

[0021] Preparation of the suspension: Weigh 1g of HAp powder and add it to 50mL of the dispersion medium mixed with n-butanol and chloroform with a volu...

Embodiment 2

[0027] Preparation of hydroxyapatite powder: add 0.2g (concentration: 8g / L) polyethylene glycol to 25mL 0.5mol / L calcium nitrate solution, stir to dissolve and adjust the pH of the solution to ≥ 11.00 with ammonia water, drop by drop under magnetic stirring Add 25mL, 0.3mol / L, ammonium phosphate solution with pH ≥ 10, and finish adding in about 10 minutes. After standing still, the precipitate and solution were transferred into a stainless steel autoclave lined with polytetrafluoroethylene, and the autoclave was placed in a constant temperature drying oven for hydrothermal reaction at 200°C for 6.5 hours. After natural cooling, wash with distilled water twice, then with absolute ethanol, filter with suction, and finally dry at 100°C for 1 hour, weigh about 1.1g of hydroxyapatite powder, and store it in a weighing bottle .

[0028] Preparation of the suspension: Weigh 1g of HAp powder and add it to 50mL of the dispersion medium mixed with n-butanol and chloroform at a volume r...

Embodiment 3

[0034] Preparation of hydroxyapatite powder: add 0.2g (concentration: 8g / L) polyethylene glycol to 25mL 0.5mol / L calcium nitrate solution, stir to dissolve and adjust the pH of the solution to ≥ 11.00 with ammonia water, drop by drop under magnetic stirring Add 25mL, 0.3mol / L, ammonium phosphate solution with pH ≥ 10, and finish adding in about 10 minutes. After standing still, the precipitate and solution were transferred into a stainless steel autoclave lined with polytetrafluoroethylene, and the autoclave was placed in a constant temperature drying oven for hydrothermal reaction at 200°C for 6.5 hours. After natural cooling, wash with distilled water twice, then with absolute ethanol, filter with suction, and finally dry at 100°C for 1 hour, weigh about 1.1g of hydroxyapatite powder, and store it in a weighing bottle .

[0035] Preparation of the suspension: Weigh 1g of HAp powder and add it to 50mL of the dispersion medium mixed with n-butanol and chloroform with a volume...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com